A copper-based powder metallurgy friction material for wet synchronizer rings

A technology of powder metallurgy and friction materials, which is applied in the field of automobile friction materials, can solve the problems of not finding the anti-overload capacity of materials, not finding the ratio of static and dynamic friction coefficients, and protection content against extreme pressure loads, so as to improve the utilization of materials rate, stable friction coefficient, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

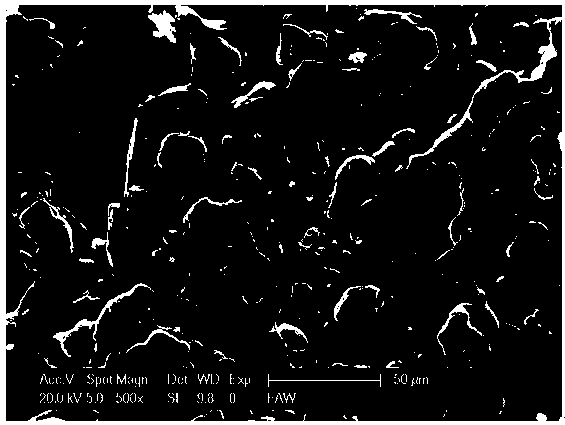

Image

Examples

Embodiment 1

[0039] The powder mixing operation is carried out according to the following components and proportions: 2.31% graphite, 1.96% Al, 0.57% SiO 2 (Natural quartz sand), 0.71% Fe, 4.21% Mo, 2.89% Sn, 2.37% W, 11.71% Zn, and the rest is Cu. The mixture was pressed and formed at 390 MPa, and pressure sintered together with the steel back. The sintering temperature was 870° C., the sintering pressure was 2.3 MPa, and the holding time was 2.5 hours.

[0040] like figure 2 The density of the copper-based powder metallurgy friction material obtained by the above method is shown as 5.1g / cm 3 , the hardness is (187~198) HV0.025,

Embodiment 2

[0042] The powder mixing operation is carried out according to the following components and proportions: 3.39% graphite, 1.68% Al, 0.86% SiO 2 (Natural quartz sand), 1.02% Fe, 5.62% Mo, 1.95% Sn, 3.68% W, 13.19% Zn, and the rest is Cu. The mixture was pressed and formed at 400 MPa, and pressure sintered together with the steel back. The sintering temperature was 900° C., the sintering pressure was 2.5 MPa, and the holding time was 3.0 hours.

[0043] The density of the copper-based powder metallurgy friction material obtained by the above method is 5.3g / cm 3 , the hardness is (196~205) HV0.025.

Embodiment 3

[0045] The powder mixing operation is carried out according to the following components and proportions: 2.89% graphite, 2.23% Al, 1.03% SiO 2 (Natural quartz sand), 0.97% Fe, 4.69% Mo, 2.32% Sn, 3.75% W, 14.51% Zn, and the rest is Cu. The mixture was pressed and formed at 420 MPa, and pressure sintered together with the steel back. The sintering temperature was 880° C., the sintering pressure was 2.6 MPa, and the holding time was 3.5 hours.

[0046] The density of the copper-based powder metallurgy friction material obtained by the above method is 5.4g / cm 3 , the hardness is (203~212) HV0.025.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com