Tool for detecting gear excircle of odd teeth

A technology for detecting teeth and odd numbers. It is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices. It can solve problems such as uncontrollable, error-prone, and cumbersome detection methods, and achieve the effect of simple detection and guaranteed accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0018] Combine below Figure 1 to Figure 4 The technical solution provided by the present invention is described in more detail.

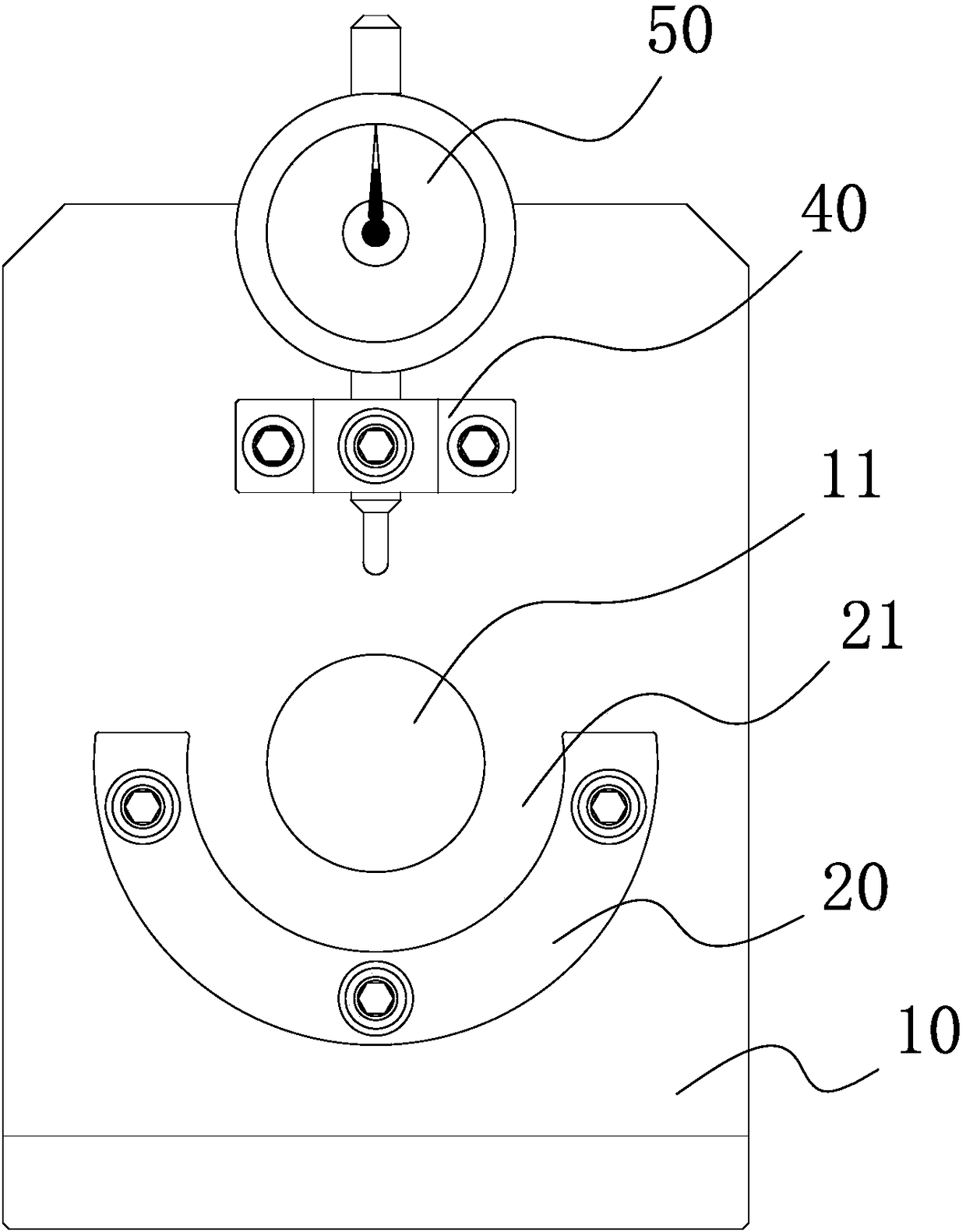

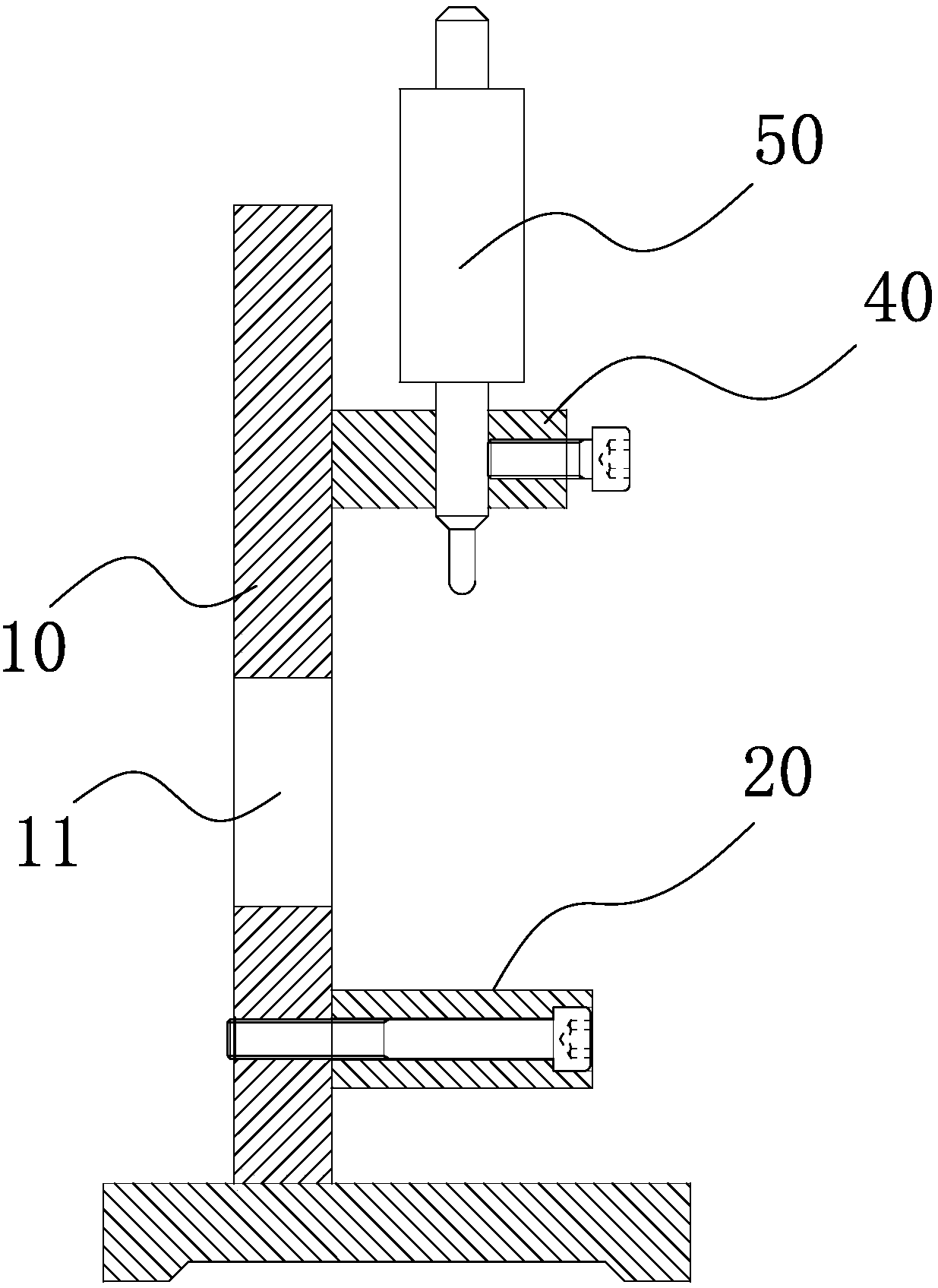

[0019] Such as Figure 1 to Figure 4 As shown, the gear outer circle tooling with an odd number of teeth in this detection includes:

[0020] The clamp base 10 is provided with a through hole 11 in the middle of the clamp base 10;

[0021] The special gauge block 20 is arranged as a semi-circular structure. The middle part of the special gauge block 20 is provided with a groove 21 with the opening facing upward. The special gauge block 20 is fixedly installed on the fixture base 10 and the through hole 11 and the groove 21 connected;

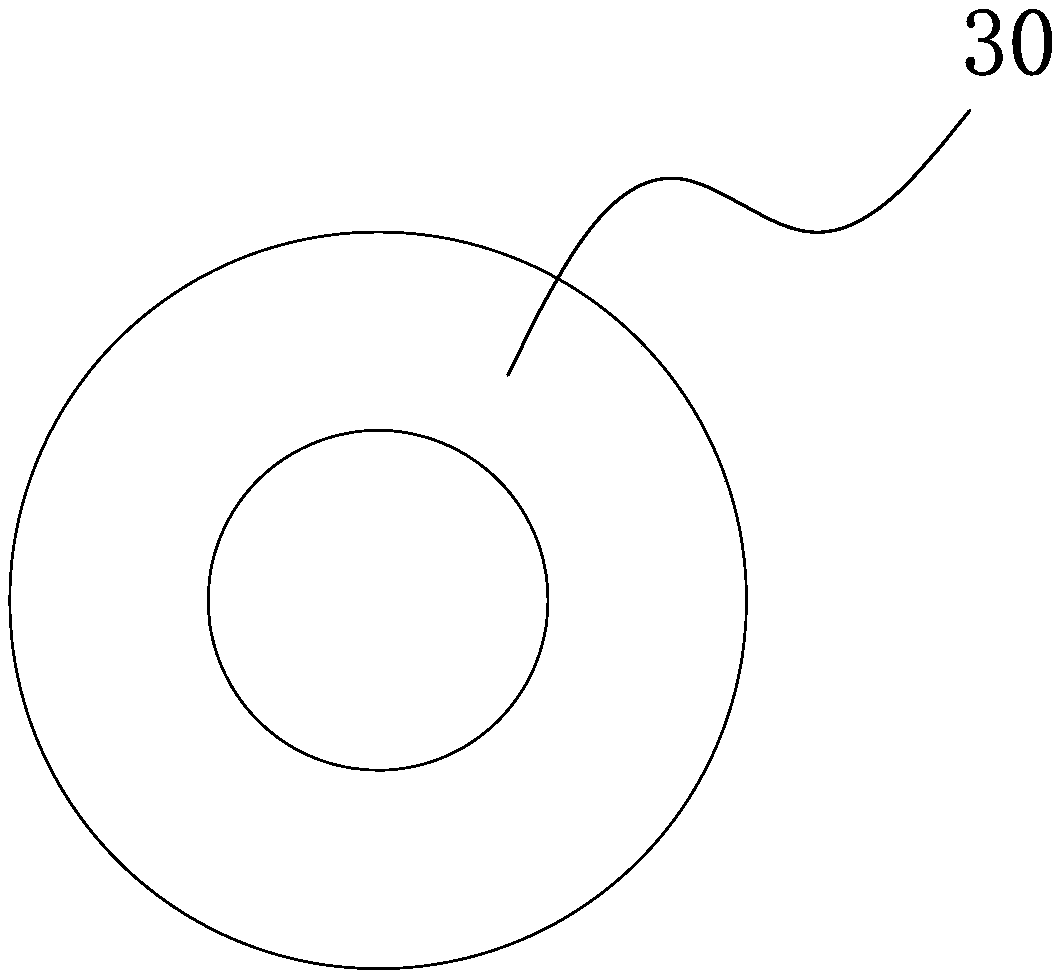

[0022] The special outer ring gauge 30 is adapted to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com