Automatic three-level carrier roller conveyor

A technology of conveyors and rollers, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of being unable to meet the multi-state requirements of automated production lines, difficult to achieve multi-functional automatic transportation, and expanding judgment errors. To achieve the effect of simple control method, high precision and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0037] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0038] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

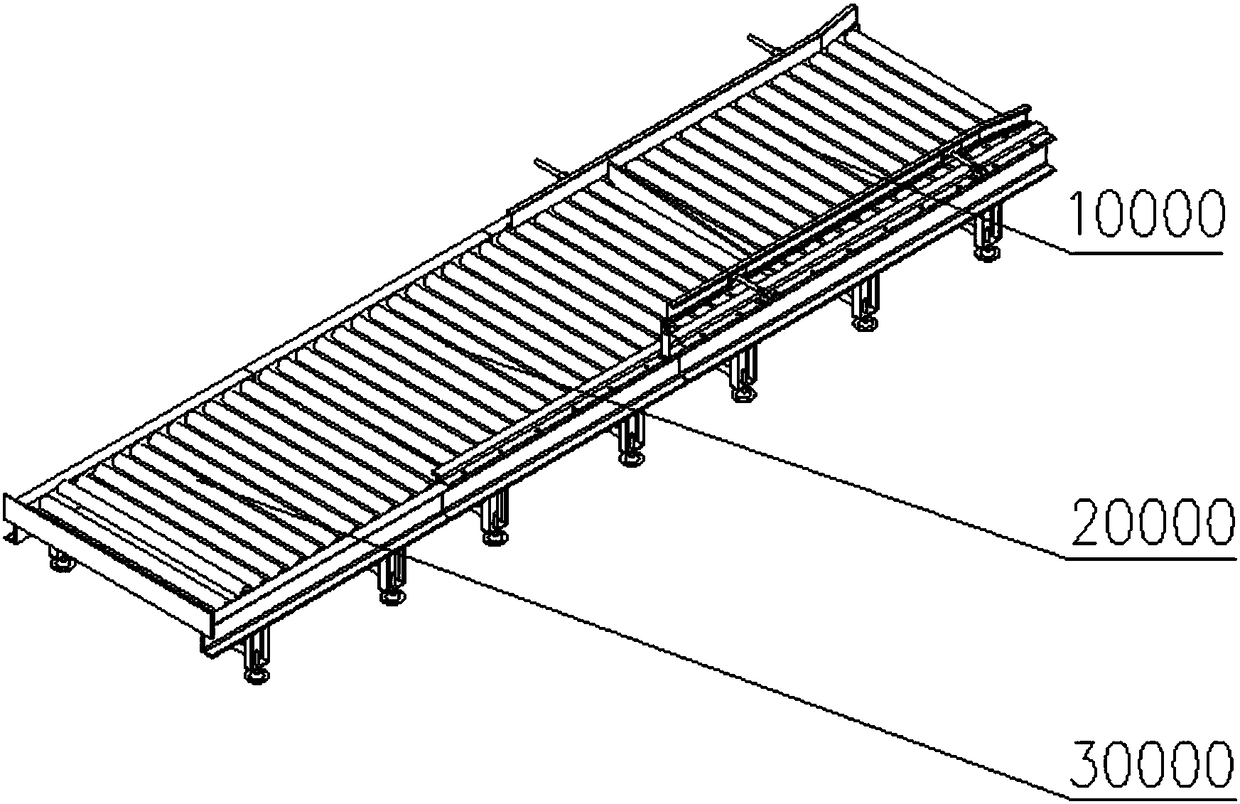

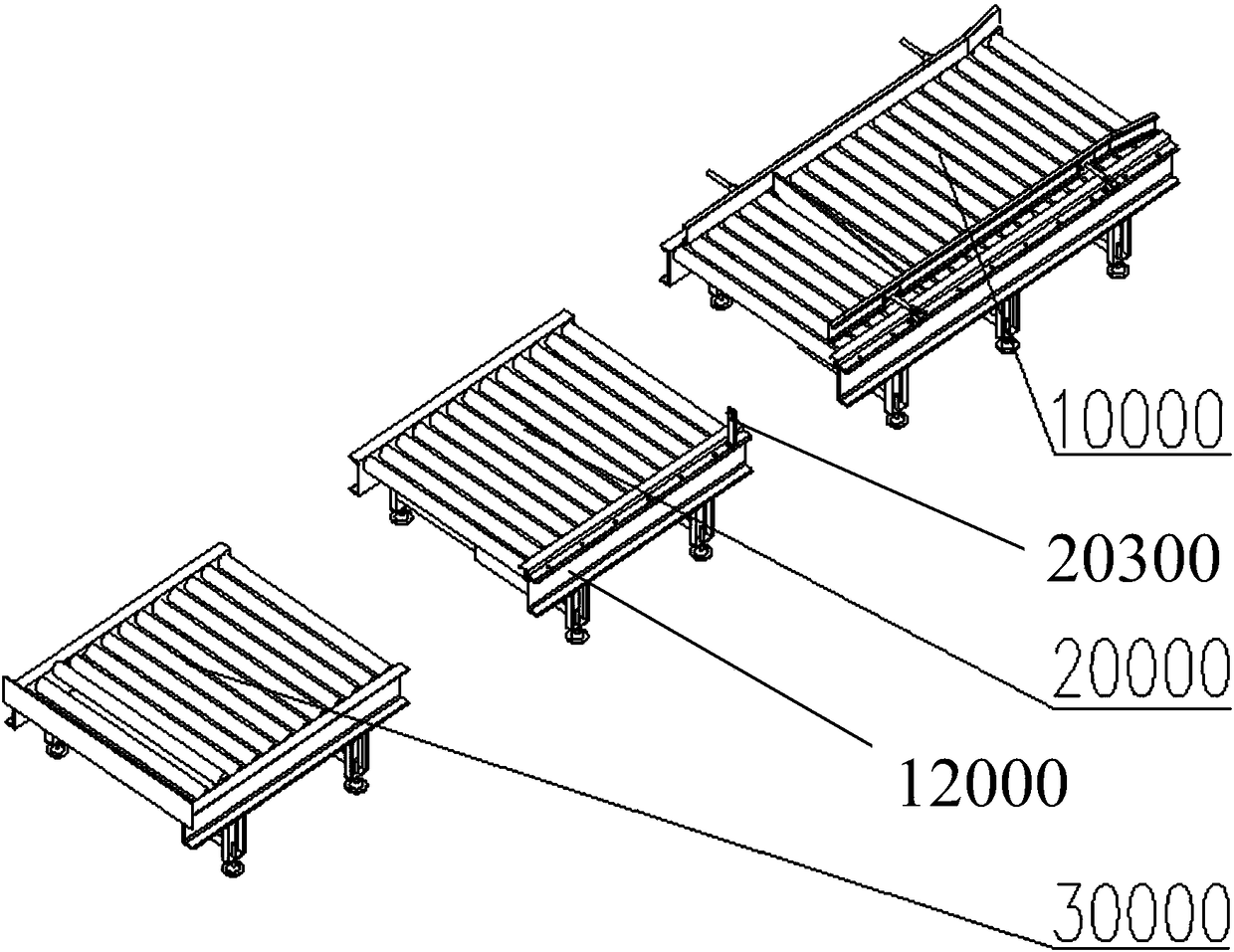

[0039] like Figure 1-2 As shown, an automatic three-stage roller conveyor in this embodiment is characterized in that it includes a main conveyor assembly 10000, an intermediate conveyor assembly 20000, and an unpowered conveyor assembly 30000 arranged in sequence along the conveying direction. The three sets of conveyor assemblies are placed on the ground in wide alignment with each other and can be bolted to the ground if required.

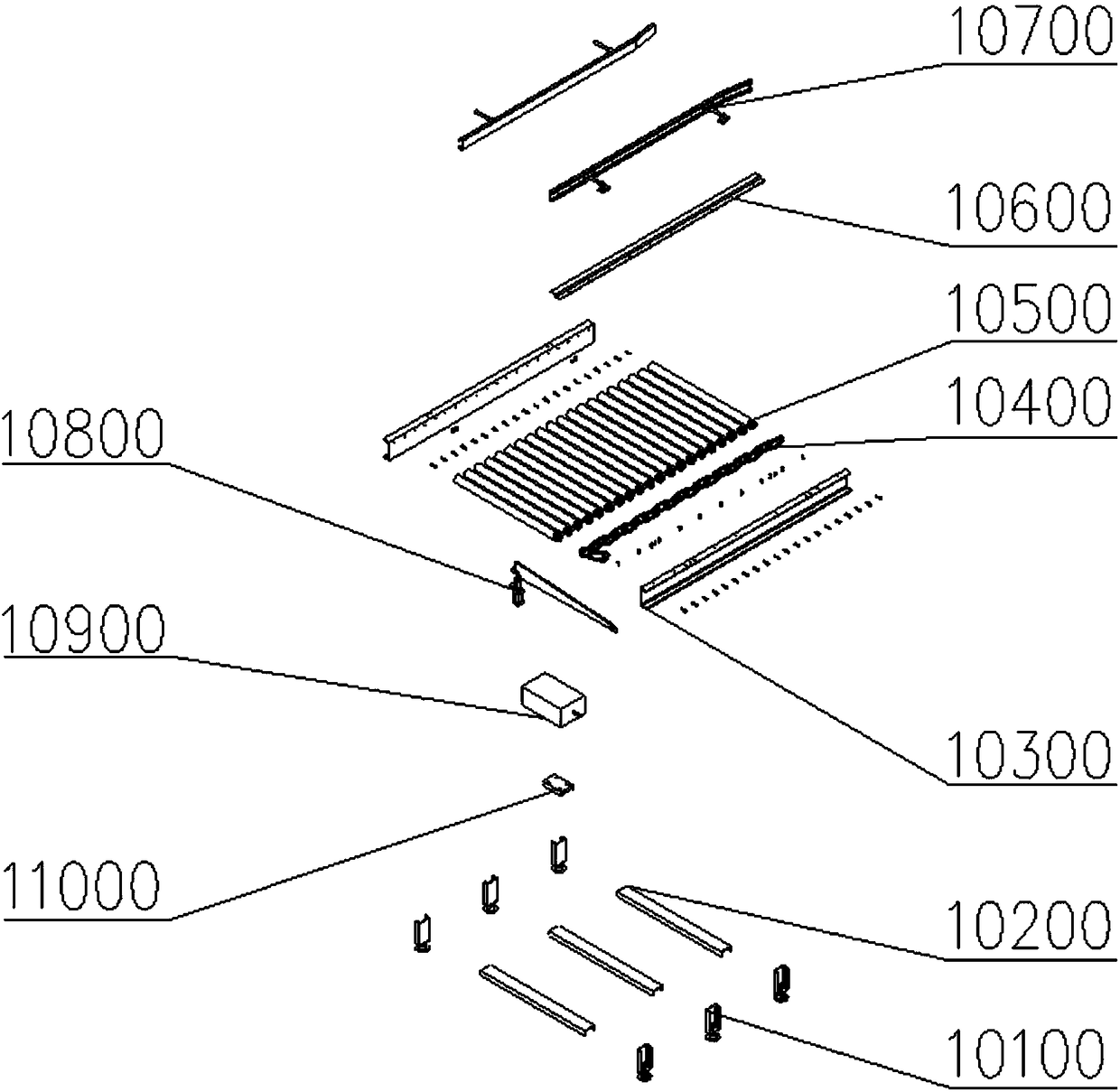

[0040] The main conveyor assembly 10000 includes a main support frame 12000, a main conveying roller assembly arranged on the main support frame 12000, a fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap