Small laser carving machine

A laser engraving machine, a small-scale technology, applied in the field of engraving, can solve the problems of inconvenient carrying, occupying a large space, etc., and achieve the effect of easy carrying, small space occupation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

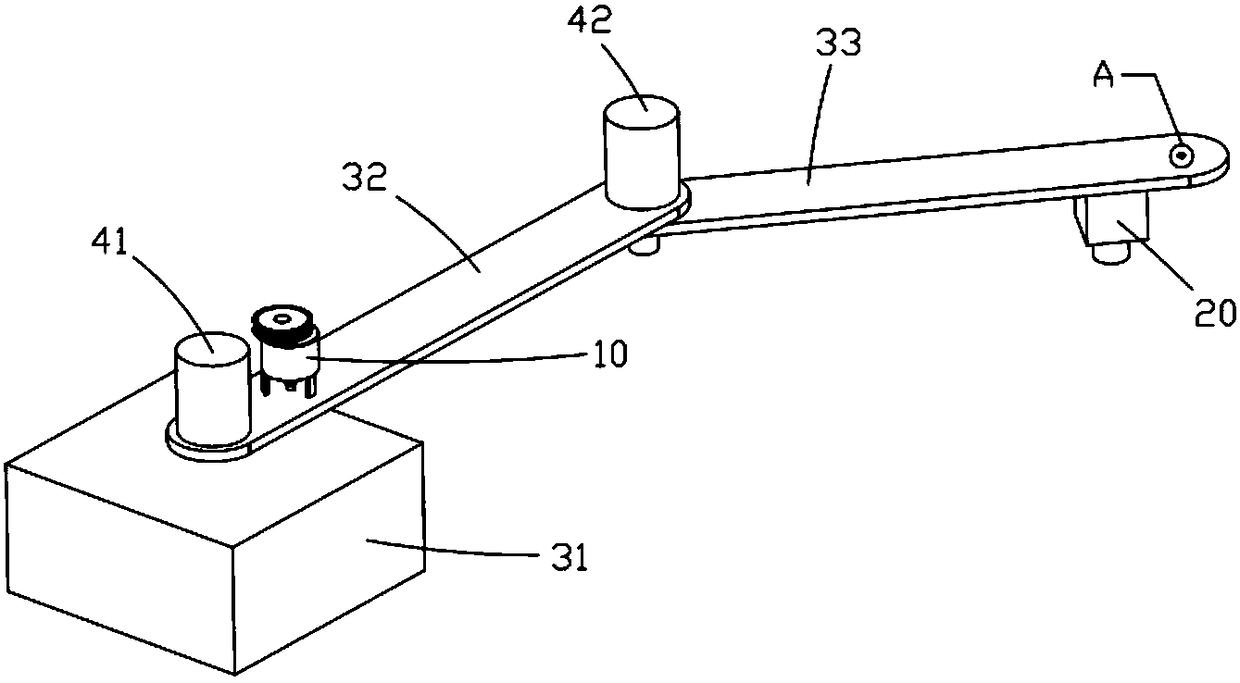

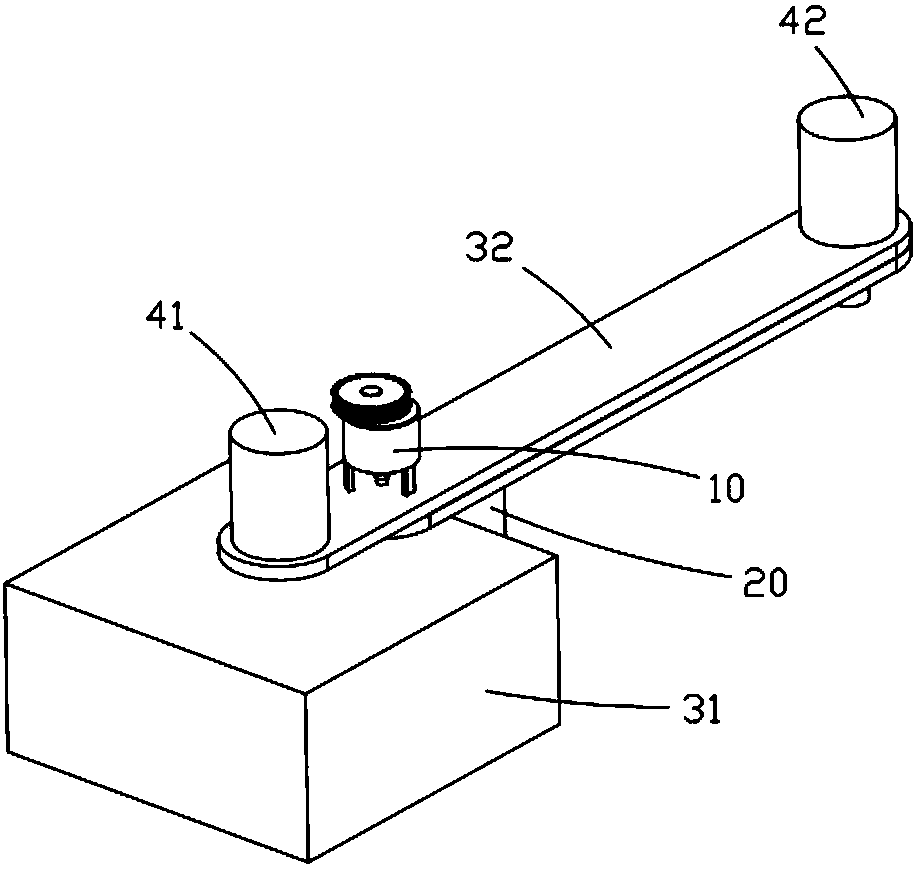

[0024] A small laser engraving machine includes a laser 20 and a driving system for driving the displacement of the laser.

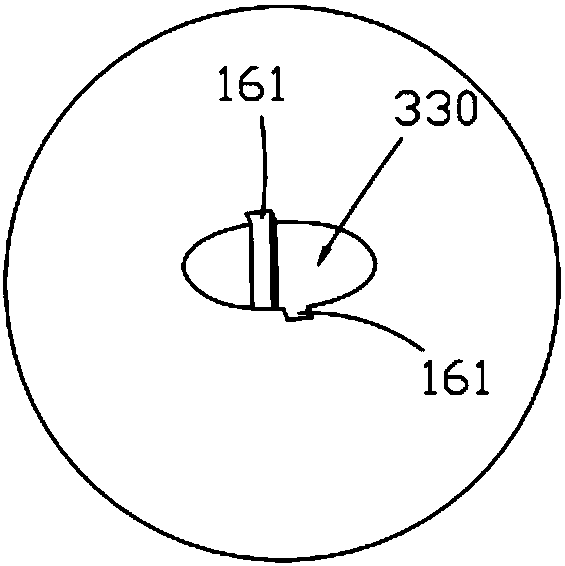

[0025] Combine figure 1 , figure 2 The driving system includes a base 31, a large arm 32, and a small arm 33. The large arm is pivotally connected to the base, the small arm is pivotally connected to the large arm, and the laser is mounted on the small arm. A servo motor 41 drives the big arm to rotate around the base, and a second servo motor 42 drives the small arm to rotate around the big arm. Wherein, the small arm 33 is located below the big arm 32, and the laser 20 is located below the small arm, so that the big arm and the small arm can be stacked up and down for storage.

[0026] The boom 32 is pivotally connected to the base 31 via a first shaft, the small arm 33 is pivotally connected to the boom via a second shaft, the first servo motor 41 is mounted on the boom, and the first servo motor Connected to the first shaft, the second servo motor 42 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap