Well drilling equipment for petroleum exploitation

A technology for drilling and equipment, which is applied in the field of drilling equipment for oil development, which can solve the problems of complex operation, low drilling efficiency, and dust that cannot be treated, and achieve the effects of simple operation, high drilling efficiency, and dust treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

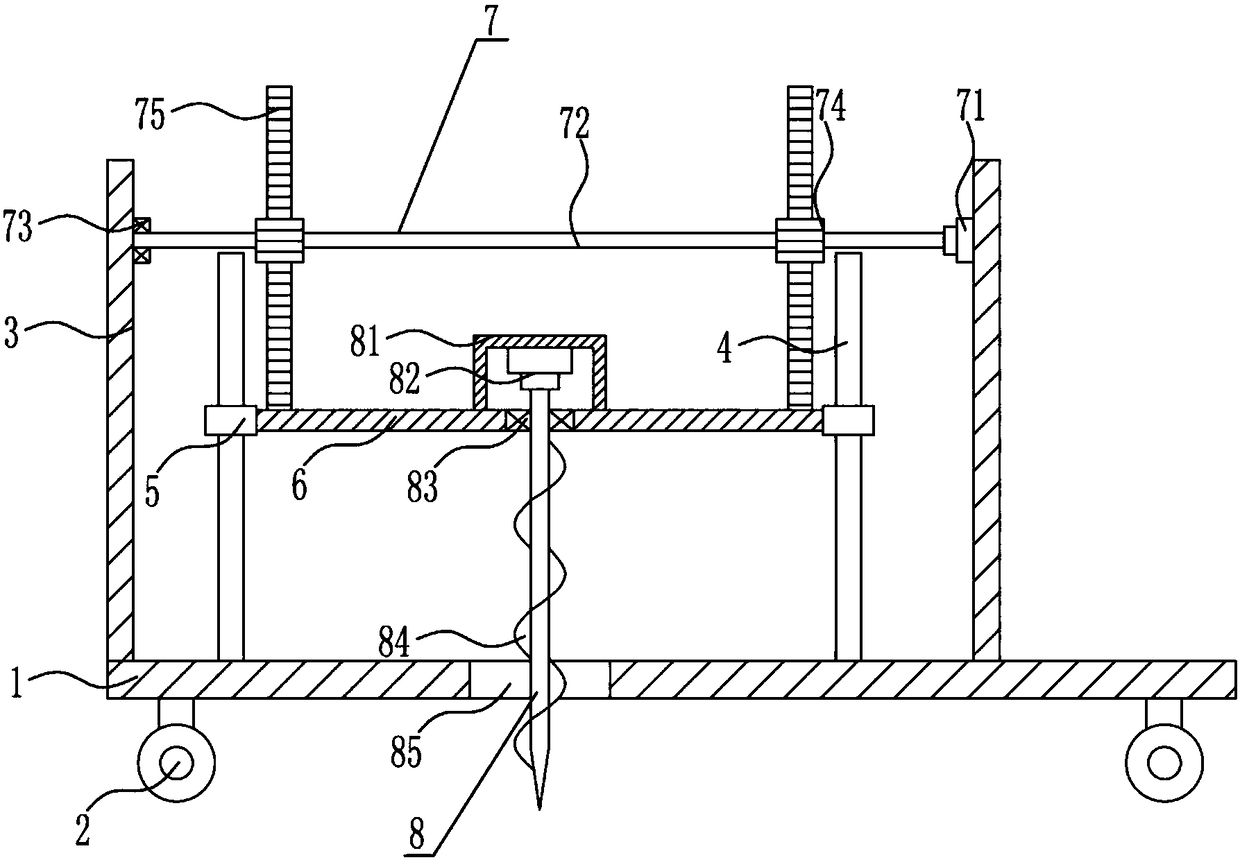

[0027] Example 1

[0028] A kind of oil exploitation uses drilling equipment, such as Figure 1-3 As shown, it includes a bottom plate 1, a wheel 2, a vertical plate 3, a guide rod 4, a guide sleeve 5, a fixed plate 6, a lifting mechanism 7 and a drilling mechanism 8. The bottom of the bottom plate 1 is provided with wheels 2, and the top of the bottom plate 1 is provided with wheels 2 on the left and right sides. The vertical plate 3, a lifting mechanism 7 is arranged on the upper part between the left and right vertical plates 3, the left and right vertical plates 3 are provided with guide rods 4 symmetrically on the left and right sides, the guide rod 4 is provided with a guide sleeve 5, and the left and right two guide sleeves 5 A fixed plate 6 is connected therebetween, and a drilling mechanism 8 is arranged in the middle of the fixed plate 6 .

Example Embodiment

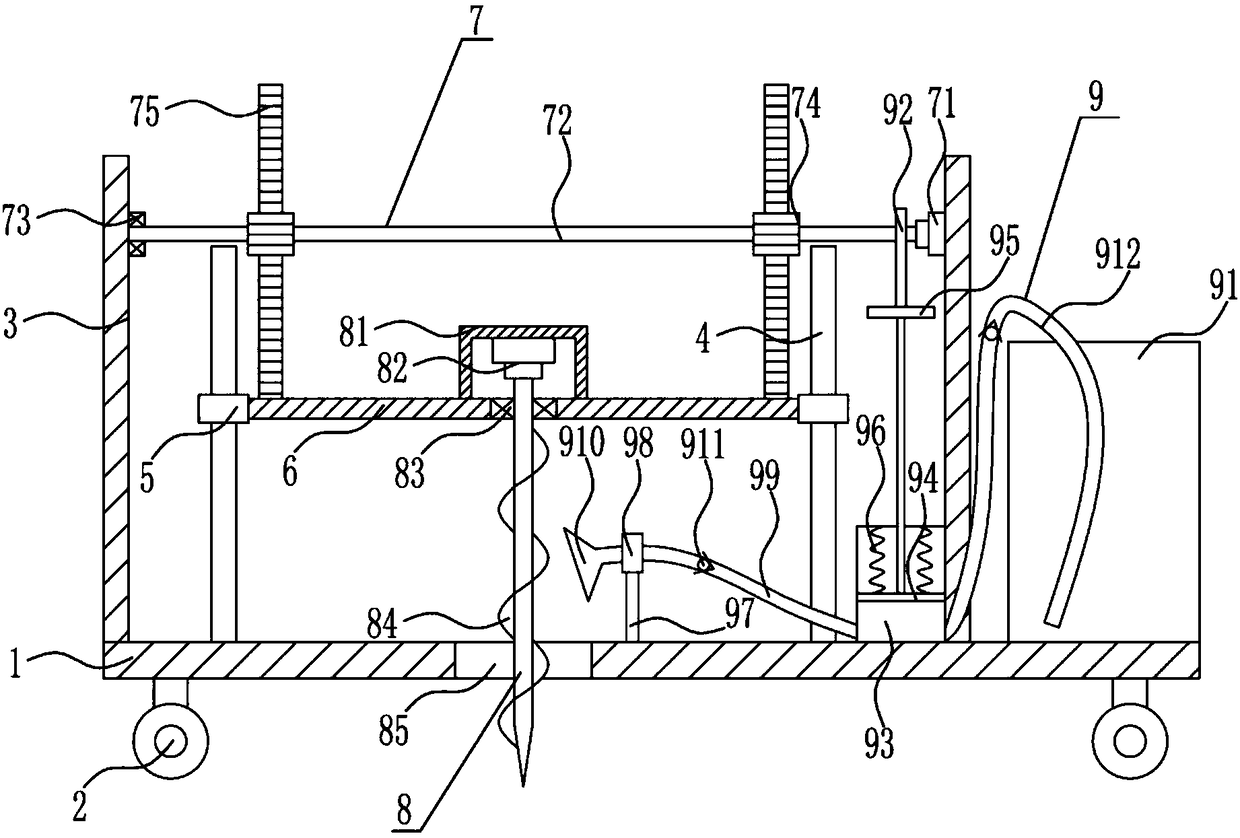

[0029] Example 2

[0030] A kind of oil exploitation uses drilling equipment, such as Figure 1-3 As shown, it includes a bottom plate 1, a wheel 2, a vertical plate 3, a guide rod 4, a guide sleeve 5, a fixed plate 6, a lifting mechanism 7 and a drilling mechanism 8. The bottom of the bottom plate 1 is provided with wheels 2, and the top of the bottom plate 1 is provided with wheels 2 on the left and right sides. The vertical plate 3, a lifting mechanism 7 is arranged on the upper part between the left and right vertical plates 3, the left and right vertical plates 3 are provided with guide rods 4 symmetrically on the left and right sides, the guide rod 4 is provided with a guide sleeve 5, and the left and right two guide sleeves 5 A fixed plate 6 is connected therebetween, and a drilling mechanism 8 is arranged in the middle of the fixed plate 6 .

[0031] The lifting mechanism 7 includes a first motor 71 , a rotating shaft 72 , a first bearing seat 73 , a gear 74 and a rac...

Example Embodiment

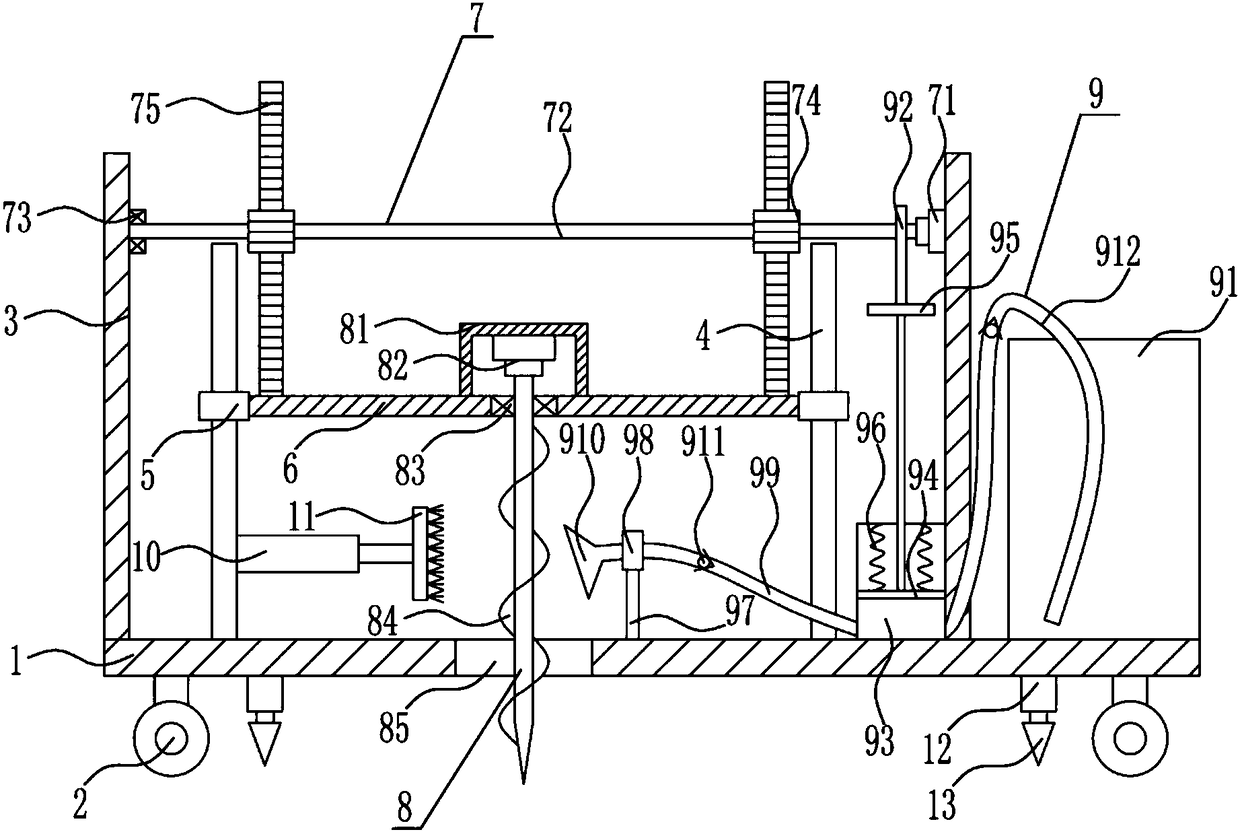

[0032] Example 3

[0033] A kind of oil exploitation uses drilling equipment, such as Figure 1-3 As shown, it includes a bottom plate 1, a wheel 2, a vertical plate 3, a guide rod 4, a guide sleeve 5, a fixed plate 6, a lifting mechanism 7 and a drilling mechanism 8. The bottom of the bottom plate 1 is provided with wheels 2, and the top of the bottom plate 1 is provided with wheels 2 on the left and right sides. On the vertical plate 3, a lifting mechanism 7 is arranged on the upper part between the left and right vertical plates 3, and a guide rod 4 is symmetrically arranged on the inner side of the left and right vertical plates 3. The guide rod 4 is provided with a guide sleeve 5, and the left and right guide sleeves 5 A fixed plate 6 is connected therebetween, and a drilling mechanism 8 is arranged in the middle of the fixed plate 6 .

[0034]The lifting mechanism 7 includes a first motor 71 , a rotating shaft 72 , a first bearing seat 73 , a gear 74 and a rack 75 , the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap