First type absorption heat pump set testing device

A technology of absorption heat pump and test device, which is applied in the direction of measuring device, testing of machine/structural components, instruments, etc., can solve the problems of high energy consumption, high operating cost, long debugging time, etc., to improve heat energy and reduce investment. , the effect of increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

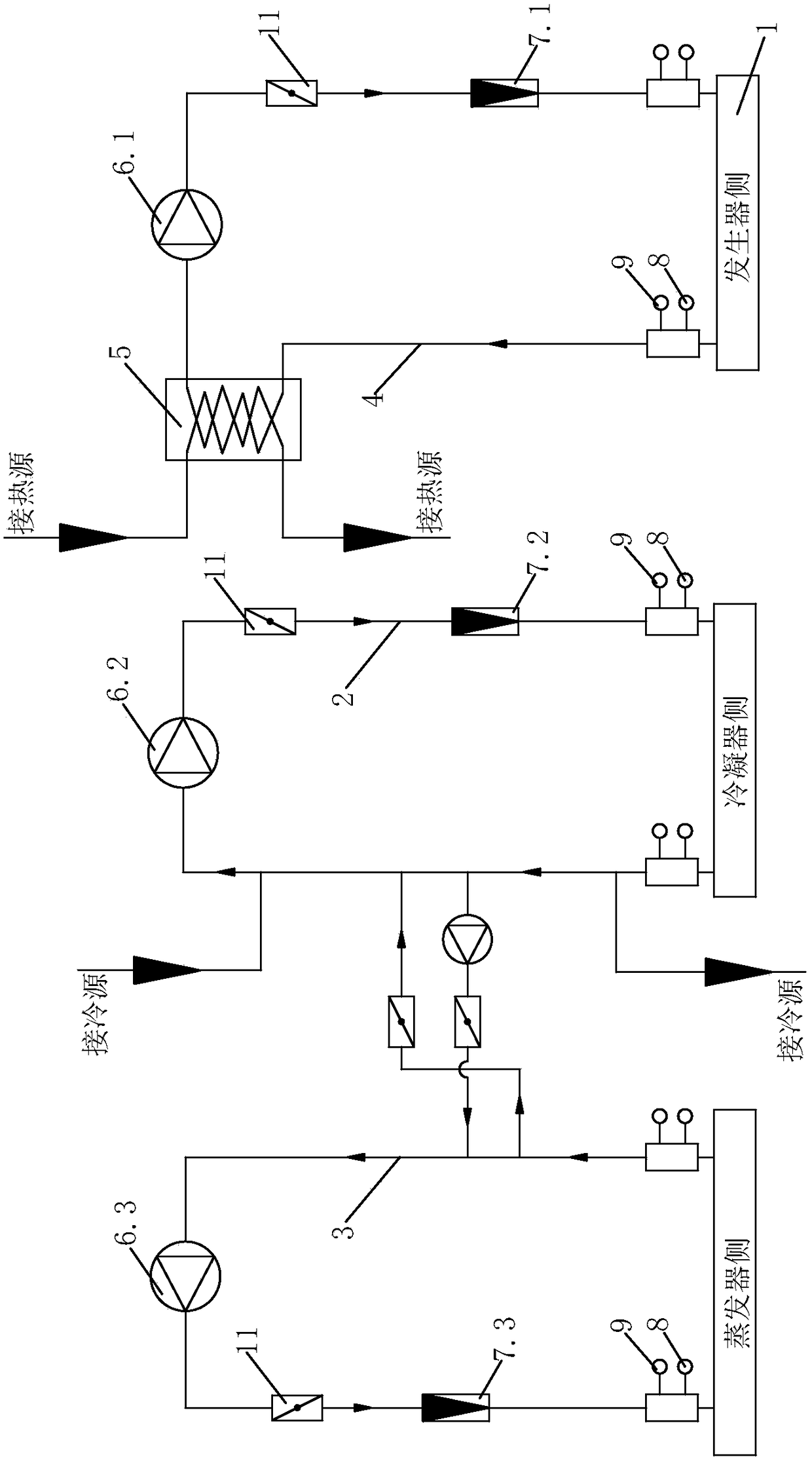

[0026] The first type of absorption heat pump is also called heat-increasing heat pump. Such as figure 1 As shown, a test device of the first type of absorption heat pump unit includes an evaporator side circulation pipeline 3 connected to the evaporator and a condenser side circulation pipeline 2 connected to the condenser, and the evaporator side circulation pipeline The pipeline 3 communicates with the condenser side circulation pipeline 2 through the water mixing circulation pipeline, and the water mixing circulation pipeline is provided with a water mixing pump controlled by frequency conversion and a valve for controlling the opening and closing of the pipeline. The connected generator side circulation pipeline 4, the generator side circulation pipeline 4 is connected with a heat exchanger 5, and the heat exchanger 5 is connected to a heat source, through which the heat exchanger 5 will enter the circulation of the generator 1 The water is warmed up, that is, the low-te...

Embodiment 2

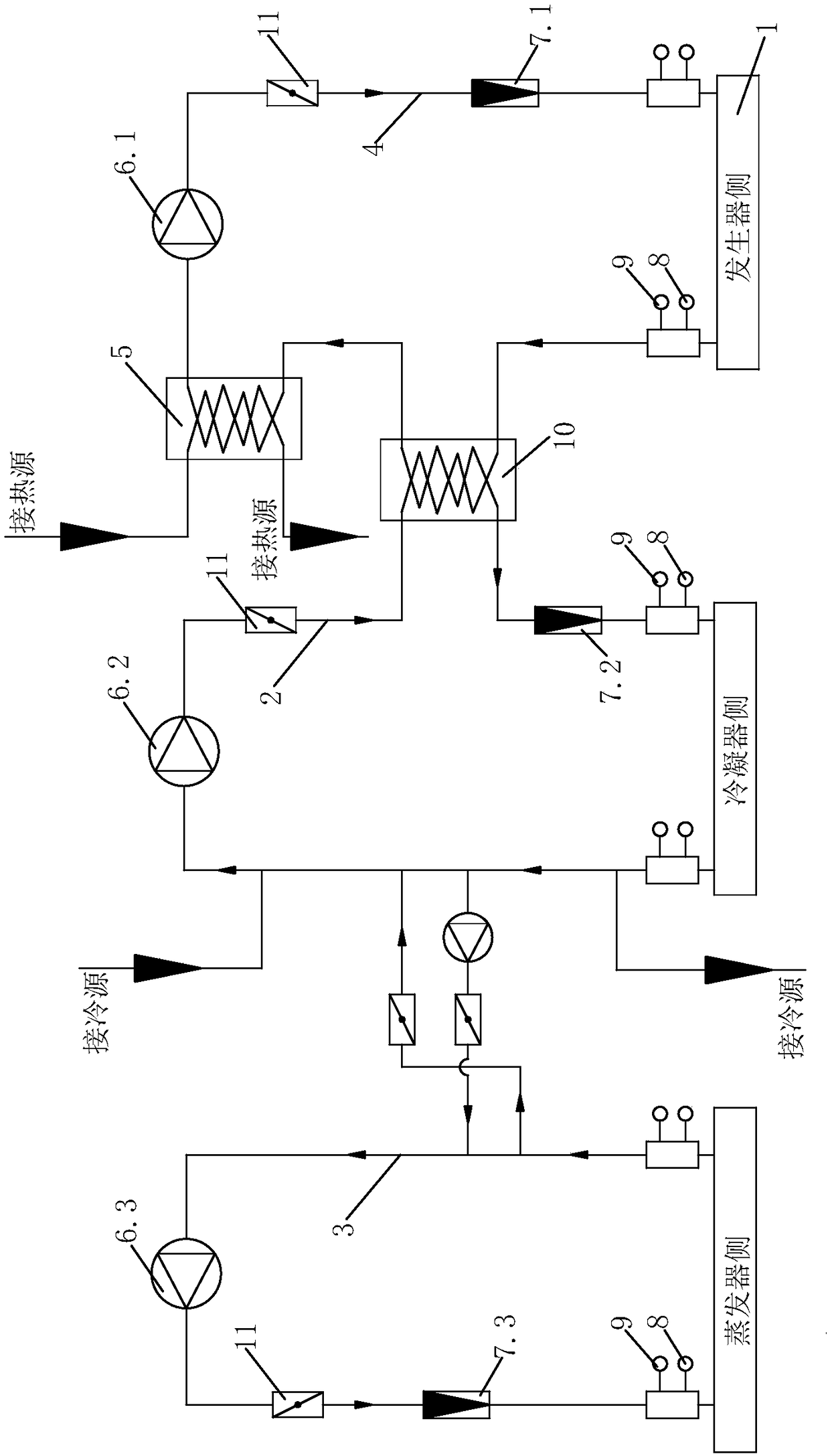

[0029] Such as figure 2 As shown, on the basis of Example 1, an auxiliary heat exchanger 10 is connected to the generator side circulation pipeline 4, and the auxiliary heat exchanger 10 is located between the heat exchanger 5 and the outlet of the generator 1 , the auxiliary heat exchanger 10 is also connected to the condenser side circulation pipeline 2, and is arranged between the cooling water pump 6.2 and the inlet of the condenser. Through such an arrangement, the low-temperature circulating water flowing out of the generator 1 passes through the auxiliary heat exchanger 10 and exchanges heat with the medium-temperature cooling water in the condenser-side circulation pipeline 2, and then enters the heat exchanger 5 to be heated by an upstream external heat source. , which undoubtedly reduces the input of the heat source, and the temperature of the cooling water is lowered after heat exchange, thereby reducing the input amount of the cold source that plays a role in bala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com