Pressure detection method and application thereof

A detection method and pressure technology, which are applied in the measurement, measurement force, and measurement device of the property force of piezoelectric resistance materials, etc. problem, to achieve the effect of reliable temperature acquisition and accurate numerical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0047] Example 1:

[0048] A pressure detection method, the adopted hardware includes a pressure sensor 1, a temperature sensor 2, a memory 3 and a controller 4, including the following steps:

[0049] Step 1: Obtain the pressure value at the first moment through the pressure sensor 1, and obtain the temperature value at the first moment through the temperature sensor 2; the first moment is a certain moment in the detection process, not specified, with a detection duration of 1 hour For example, the first moment may specifically be a certain time point within one hour. For temperature and pressure detection, the inspection amount of the temperature value and the pressure value is related to the detection frequency. Before step 1, the temperature sampling frequency of the temperature sensor 2 can be set. By setting the temperature sampling frequency, the number of temperature values can be increased, which facilitates more accurate temperature collection and feedback. When ...

Example Embodiment

[0066] Example 2:

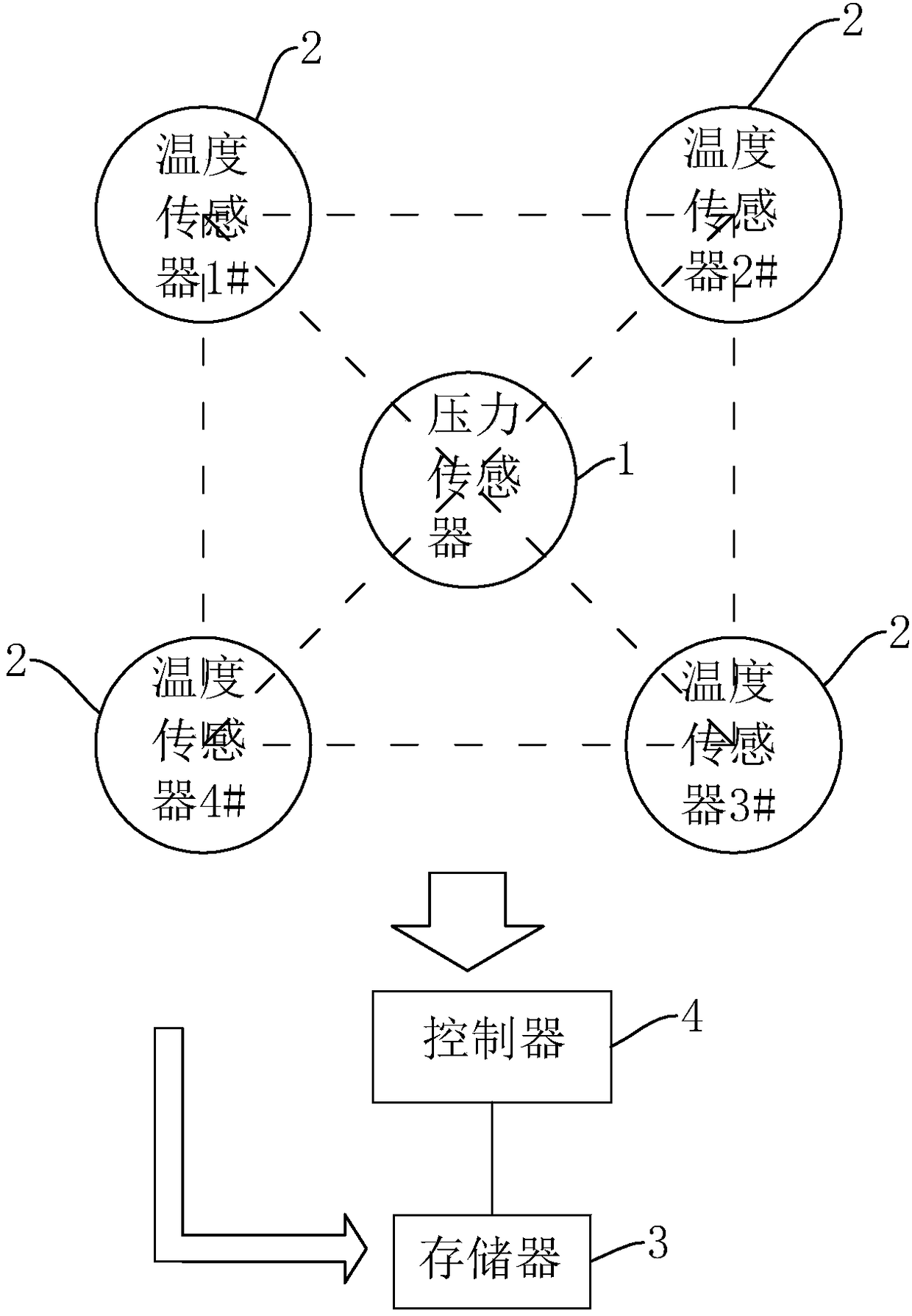

[0067] A pressure detection device such as figure 1 As shown, based on the above implementation method, it includes a pressure sensor 1, a temperature sensor 2, a memory 3 and a controller 4. The pressure sensor 1 is connected to the controller 4 to obtain the pressure value at the first moment and transmit it to the controller 4 and the memory 3;

[0068] The temperature sensor 2 is connected to the controller 4 for acquiring the temperature value at the first moment, and transmitting it to the controller 4 and the memory 3;

[0069] The controller 4 is connected to the memory 3 for calling the temperature drift coefficient, the lower limit temperature value, the upper limit temperature value, the pressure value and the temperature value in the memory 3 .

[0070] Determine whether the temperature value at the first moment is in the range between the lower limit temperature value and the upper limit temperature value: S41, when the temperature is less th...

Example Embodiment

[0075] Example 3:

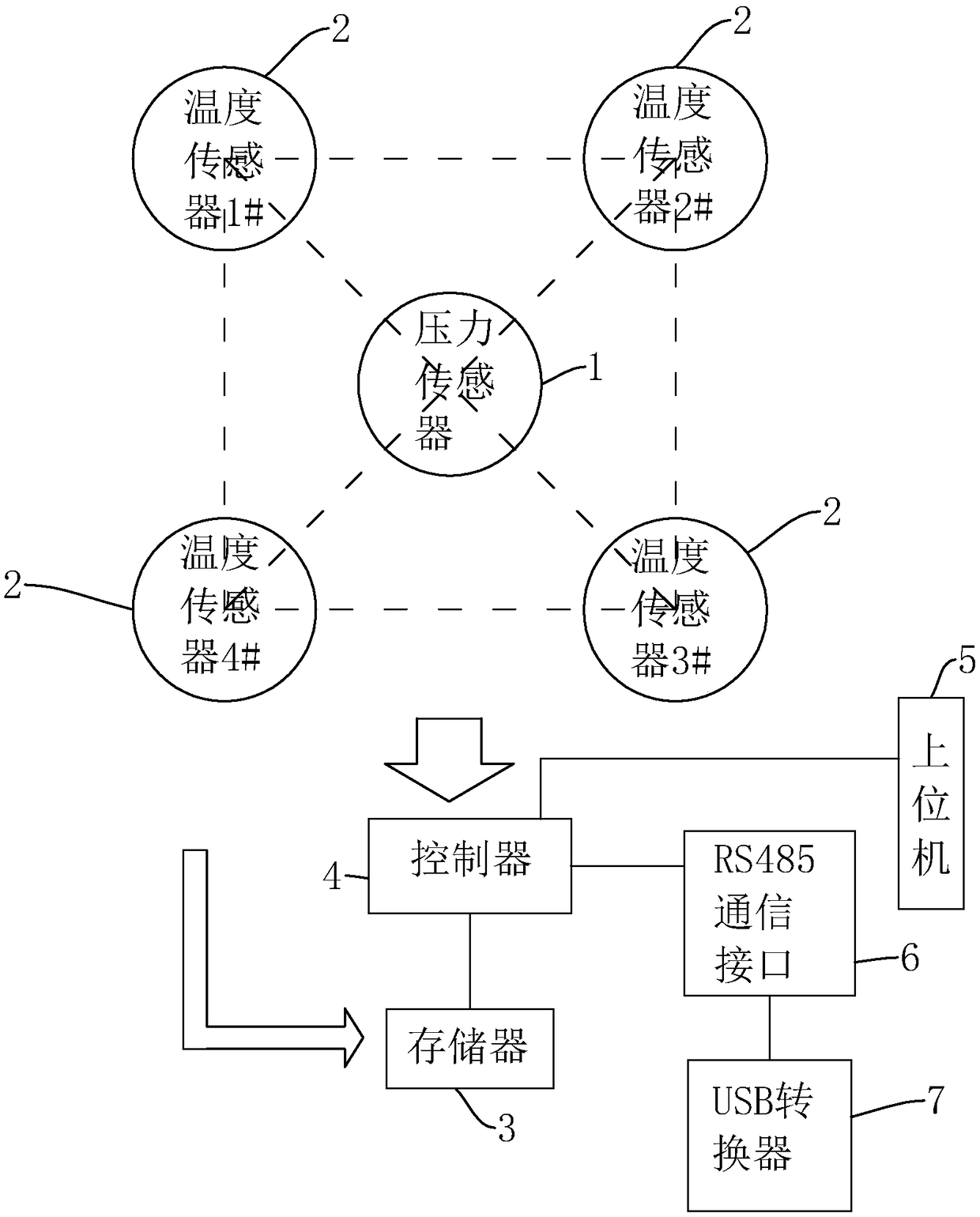

[0076] A water pump, based on embodiment 1, such as figure 2 As shown, including the above-mentioned pressure detection device, the memory 3 in the pressure detection device is connected to the upper computer 5, and the upper computer 5 is used to display the temperature drift coefficient, the lower limit temperature value, the upper limit temperature value, the pressure value, and the temperature value. The host computer 5 can be a microcontroller 4, a display, a PC, or the like.

[0077] The above-mentioned pressure detection device is applied to the water pump, and by connecting the upper computer 5, the data can be displayed intuitively, which is convenient for the operator to control and debug.

[0078] The host computer 5 has an RS485 communication interface 6 for communicating with external devices. Using RS485 communication interface 6, it can communicate with external devices and extract and modify data. The RS485 communication interface 6 is a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap