Automatic welding device for main girder web reinforcing steel of crane

A main girder web and automatic welding technology, applied in auxiliary devices, welding accessories, welding equipment, etc., can solve the problems of narrow space, increased cost, low production efficiency, etc., achieve a high degree of automation, prevent web deformation, and weld fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention and not to limit the present invention.

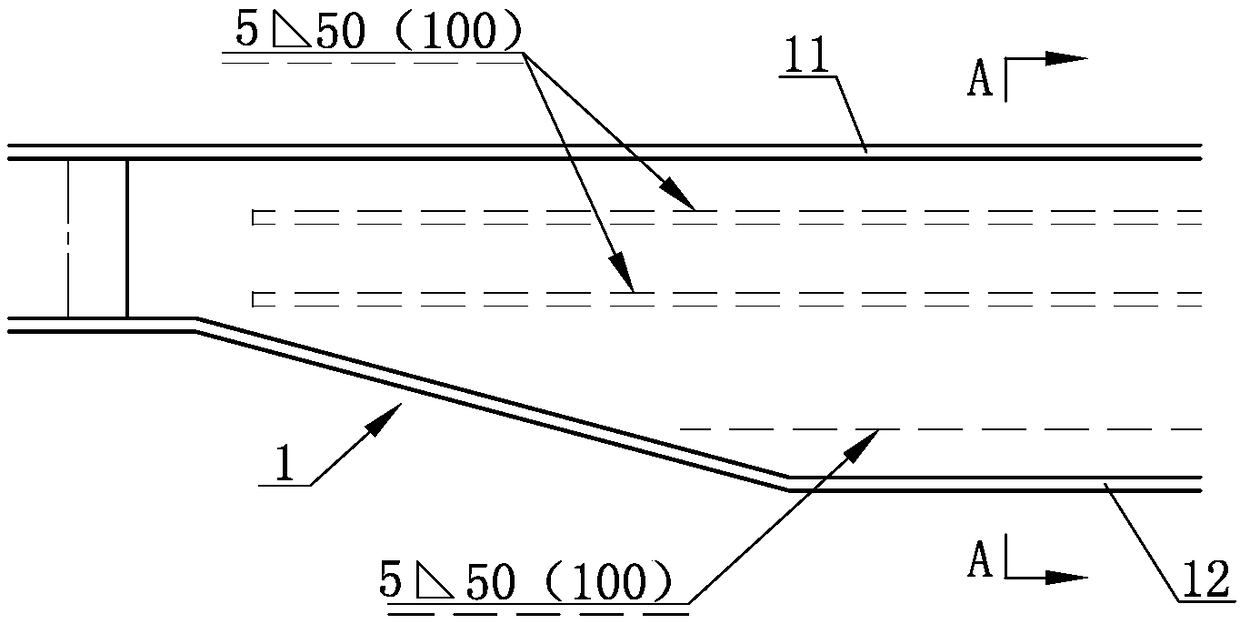

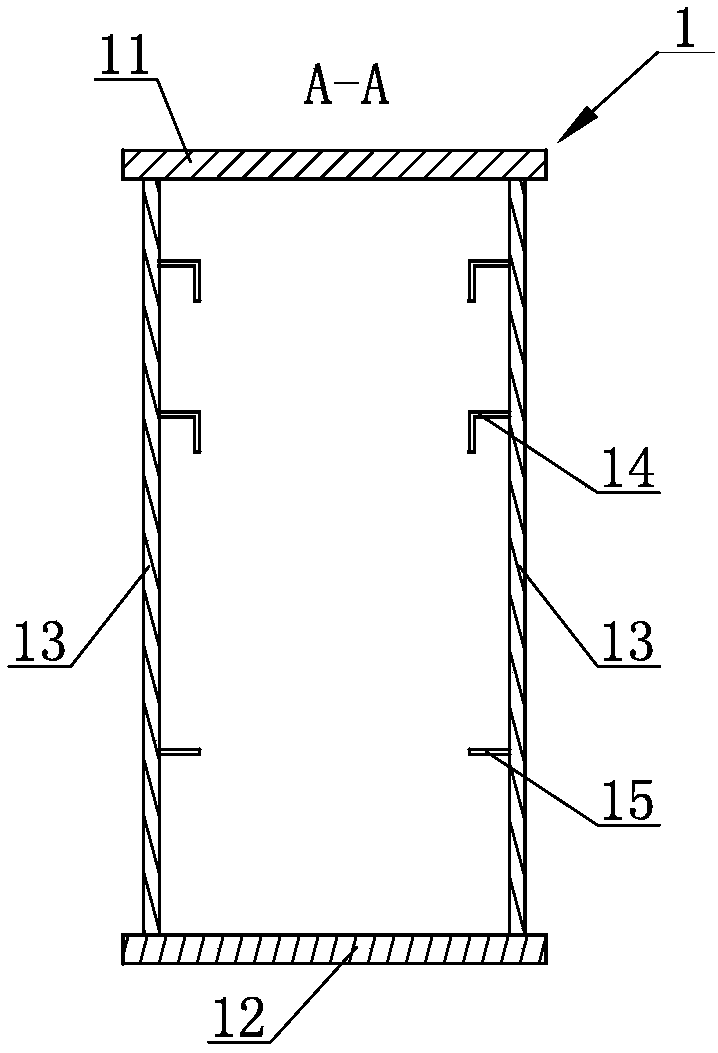

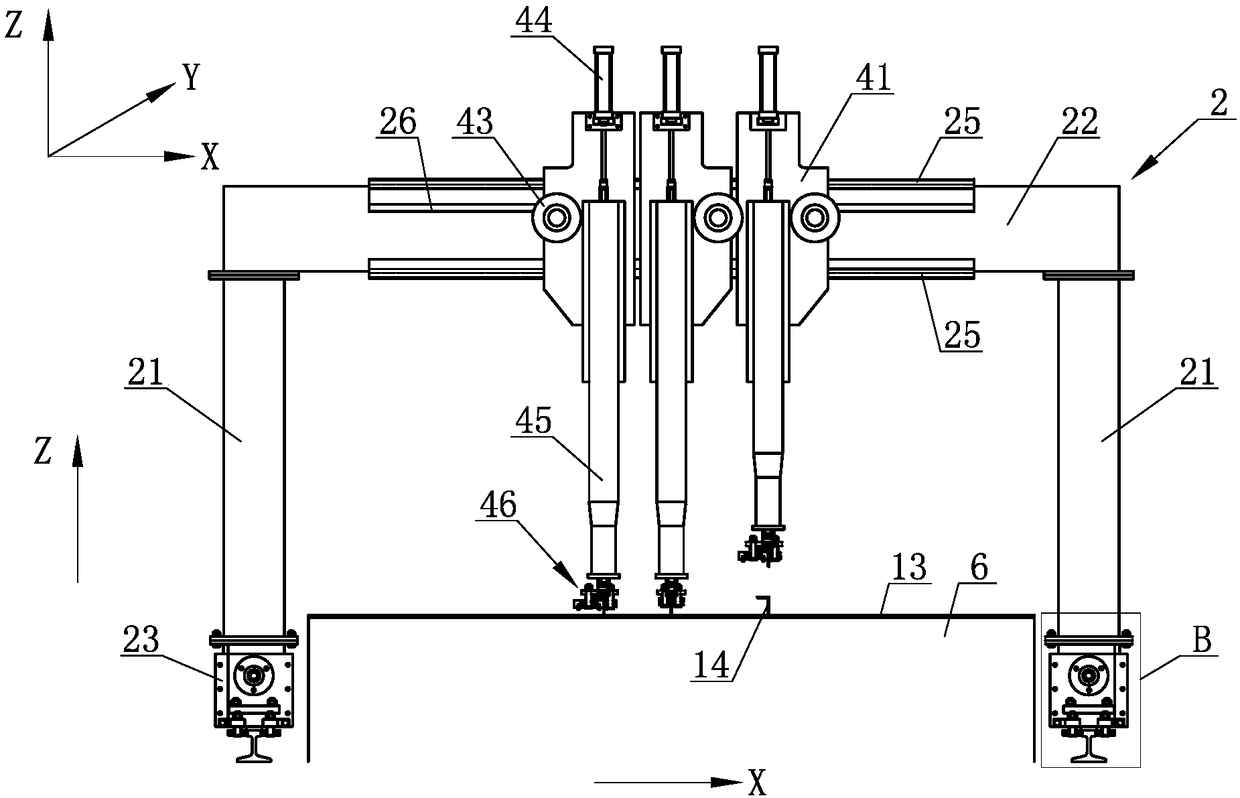

[0036] Define the XYZ coordinate system as image 3 shown.

[0037] Such as image 3 , Figure 4 and Figure 5 Commonly shown, an automatic welding device for crane main girder web reinforcement steel, a Π-shaped gantry 2, the gantry 2 includes two columns 21 and a beam 22 fixed on the upper ends of the two columns 21, and the lower ends of the two columns 21 They are respectively fixed on the box body 23, and the box body 23 is fixedly provided with a gantry motor and a gantry reducer driven by the gantry motor, and the output end of the gantry reducer is fixedly connected with walking roll...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap