Preparation method of UV curable organosilicon resin for direct writing molding

A technology of direct writing molding and silicone, which is applied in the direction of additive processing, etc., can solve the problems affecting the curing reaction speed of silicone resin, the resin performance of curing precision, the introduction of restricted reaction end groups, and poor compatibility, so as to improve the chemical phase. Low capacitive, meet the effect of direct writing molding, fast molding and curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

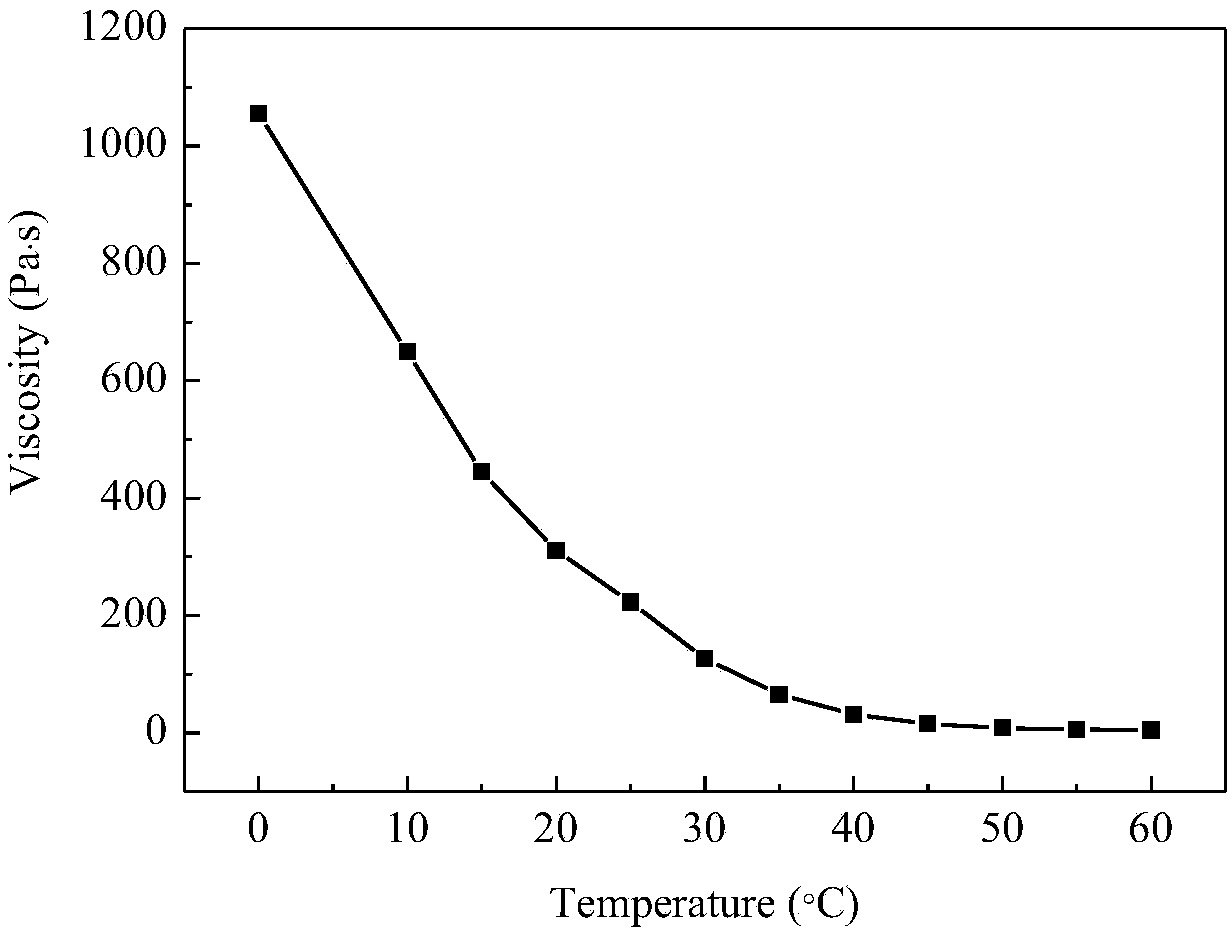

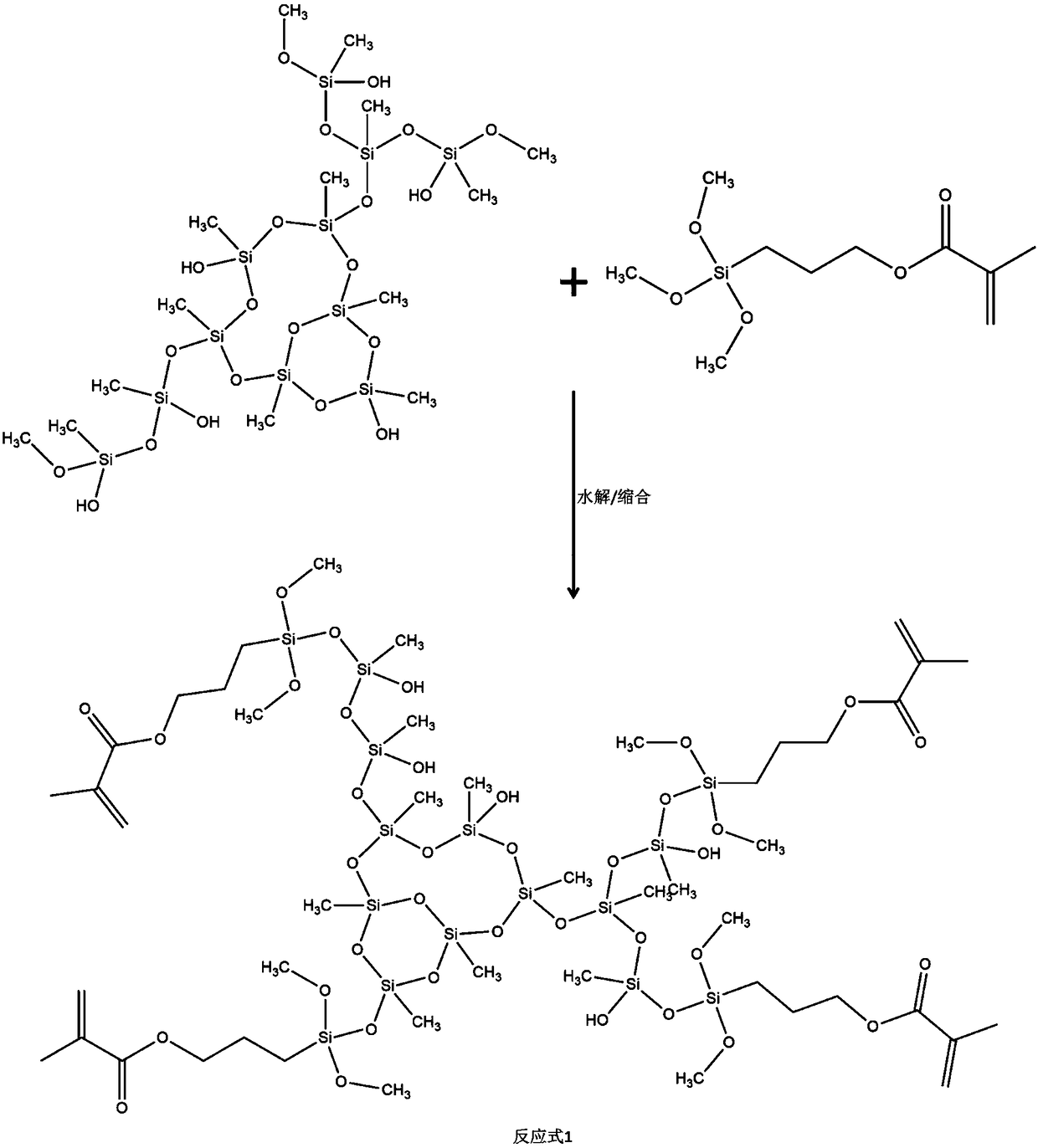

[0039] Step 1. Dissolve 20 g of hydroxyl-terminated siloxane resin and 5 g of methacryloxypropyltrimethylsilane (20.1 mmol) in 50 mL of 1,4-dioxane, stir until completely dissolved, and add 286 μL of concentrated Hydrochloric acid (0.4mmol), 362μL deionized water (20.1mmol), through N 2 protection, stirred and hydrolyzed at 20°C, and reacted for 12 hours to obtain a siloxane solution;

[0040] Step 2. Dissolve 1g of glycidyl ether methyl silsesquioxane (POSS) and 1g of hydroxypropyl acrylate in 20mL of 1,4-dioxane, add 20mg of N,N-dimethylbenzylamine, 1mg Hydroquinone, through N 2 protection, heating in an oil bath at 100°C, and reacting for 6 hours to obtain an acrylate-modified POSS intermediate;

[0041] Step 3, 1 mL of the acrylate-modified POSS intermediate 2 (0.1 g) prepared in step 2 was added dropwise to the siloxane solution (containing 5 g of reaction product siloxane) obtained in 5 mL of step 1. Stir and hydrolyze at 10°C for 2 hours, then raise the temperature t...

Embodiment 3

[0045] Step 1. Dissolve 20 g of alkoxy-terminated siloxane resin and 5 g of methacryloxypropyltrimethylsilane (20.1 mmol) in 25 mL of 1,4-dioxane, and stir at 70 rpm until completely dissolved. 286 μL concentrated hydrochloric acid (0.2 mmol), 362 μL deionized water (20.1 mmol) were added. Introduce N2 protection, stir and hydrolyze at 20°C, and react for 12 hours to obtain a siloxane solution;

[0046] Step 2: Add 1g of glycidyl ether methyl silsesquioxane (POSS) and 1g of hydroxyethyl methacrylate to 20mL of 1,4-dioxane, stir at 90rpm until completely dissolved, then add 20mg of triphenyl Based phosphine, 1mg p-benzoquinone, passed through N 2 protection, heating in an oil bath at 100°C, and reacting for 6 hours to obtain an acrylate-modified POSS intermediate;

[0047] Step 3, the acrylate-modified POSS intermediate (0.1g) prepared in 1mL step 2 was added dropwise in the siloxane solution (containing reaction product siloxane 10g) obtained in 10mL step 1, in 10 Stir and ...

Embodiment 4

[0051] Step 1. Dissolve 20 g of hydroxyl-terminated siloxane resin and 5 g of methacryloxypropyltrimethylsilane (20.1 mmol) in 50 mL of ethylene glycol dimethyl ether, stir at 70 rpm until completely dissolved, and add 286 μL of concentrated Hydrochloric acid (0.4mmol), 362μL deionized water (20.1mmol), through N 2 protection, stirred and hydrolyzed at 10°C, and reacted for 16 hours to obtain a siloxane solution;

[0052] Step 2. Add 0.5g glycidyl ether methyl silsesquioxane (POSS) and 1g pentaerythritol triacrylate to 5mL ethylene glycol dimethyl ether, stir at 60rpm until completely dissolved, then add 20mg tetramethyl bromide Ammonium chloride, 1mg p-methoxyphenol, passed through N 2 protection, heating in an oil bath at 100°C, and reacting for 6 hours to obtain an acrylate-modified POSS intermediate;

[0053] Step 3, the acrylate-modified POSS intermediate (0.3g) prepared in 1mL step 2 was added dropwise to the siloxane solution (containing 10g of reaction product siloxa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com