Fabric dyeing machine

A technology for dyeing machines and fabrics, which is applied to textile processing machine accessories, textile material processing, and textile material processing equipment configuration. Efficiency improvement and moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention.

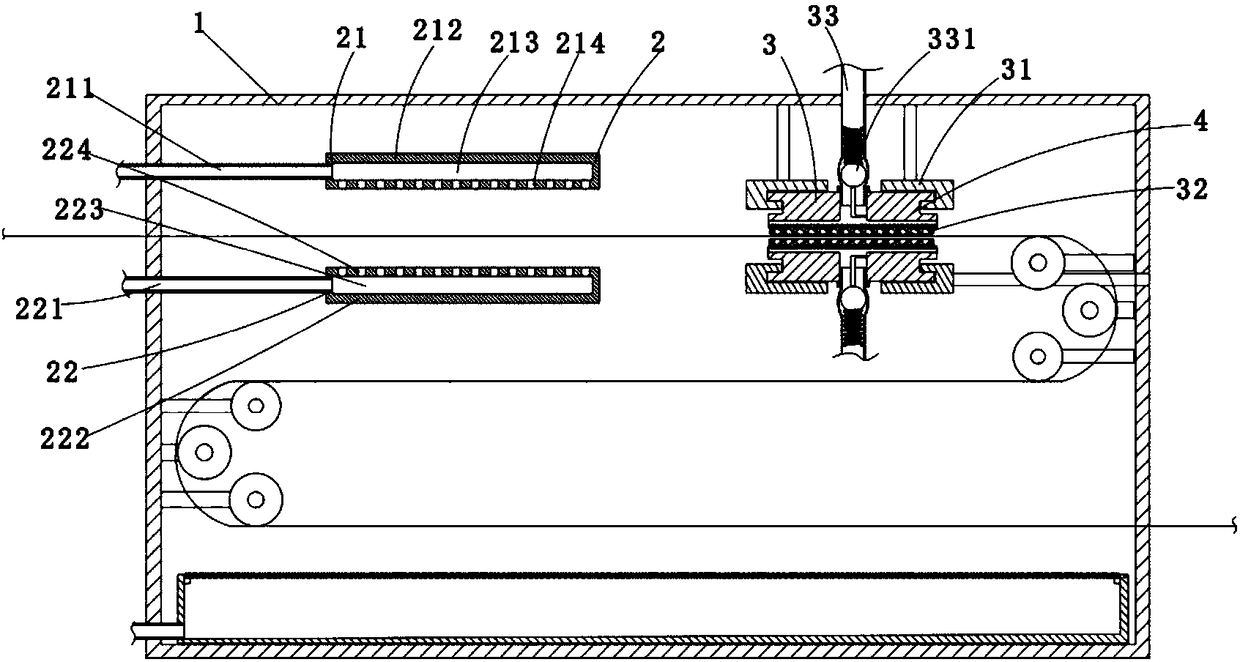

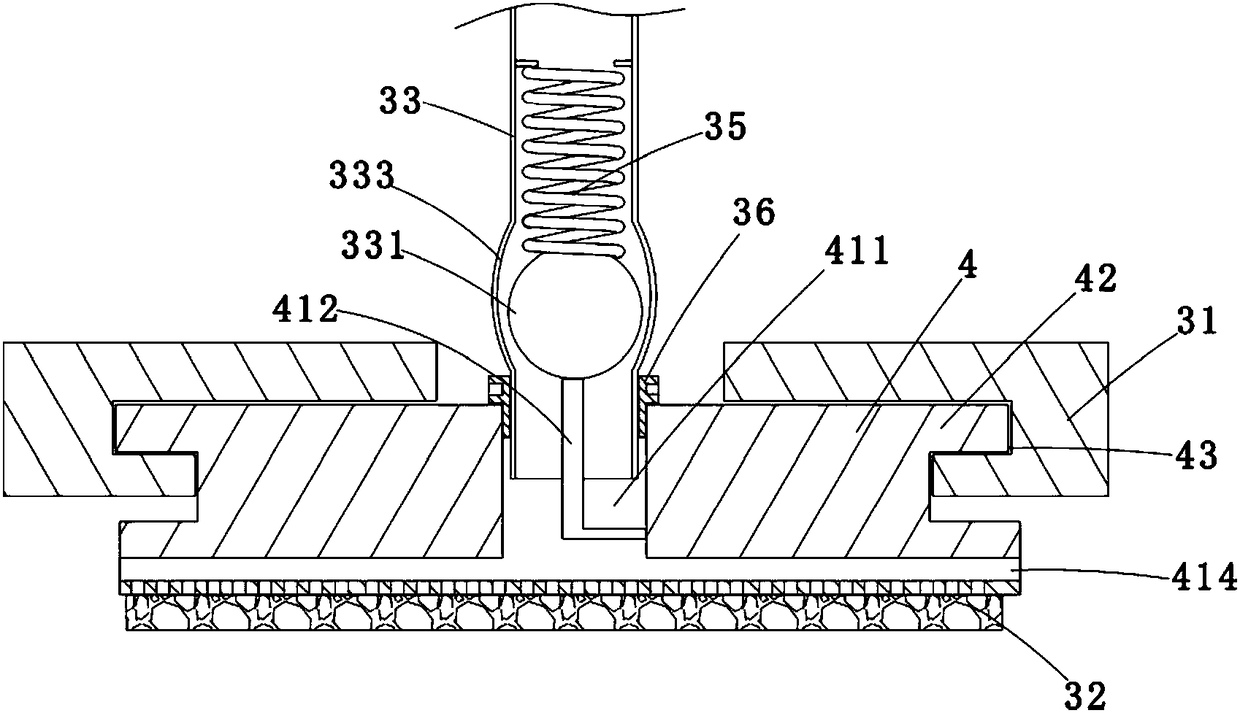

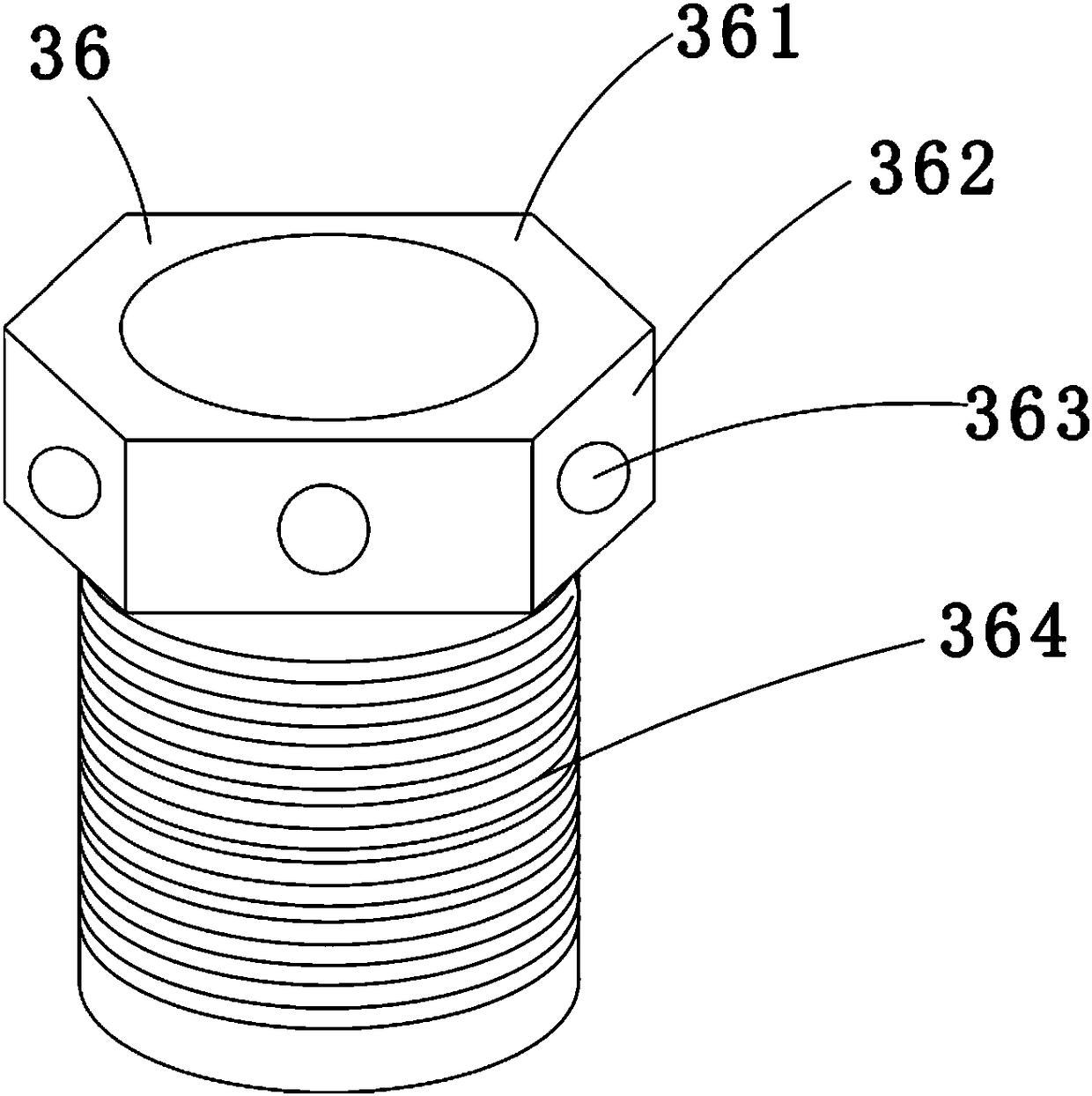

[0015] Such as Figure 1-3 As shown, a cloth dyeing machine includes a box body 1, a spray device 2 and a smoothing device 3. The box body 1 is a metal box, and the box body 1 has an openable box door, and the box body 1 The left and right side walls respectively have openings. The cloth penetrates from one side of the box 1 and exits from the other side. There are multiple metal rollers in the box 1, and the cloth does not pass through the metal rollers and is pulling In this case, the cloth moves continuously in the box 1; at the bottom of the box 1, there is a wetted pan 11, and the dye liquid will drip onto the wetted pan 11, which is a metal pan; The dye solution on...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap