Separation device and separation method

A separation device and separation method technology, which is applied in recycling technology, mechanical material recycling, plastic recycling, etc., to achieve the effect of easy separation and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

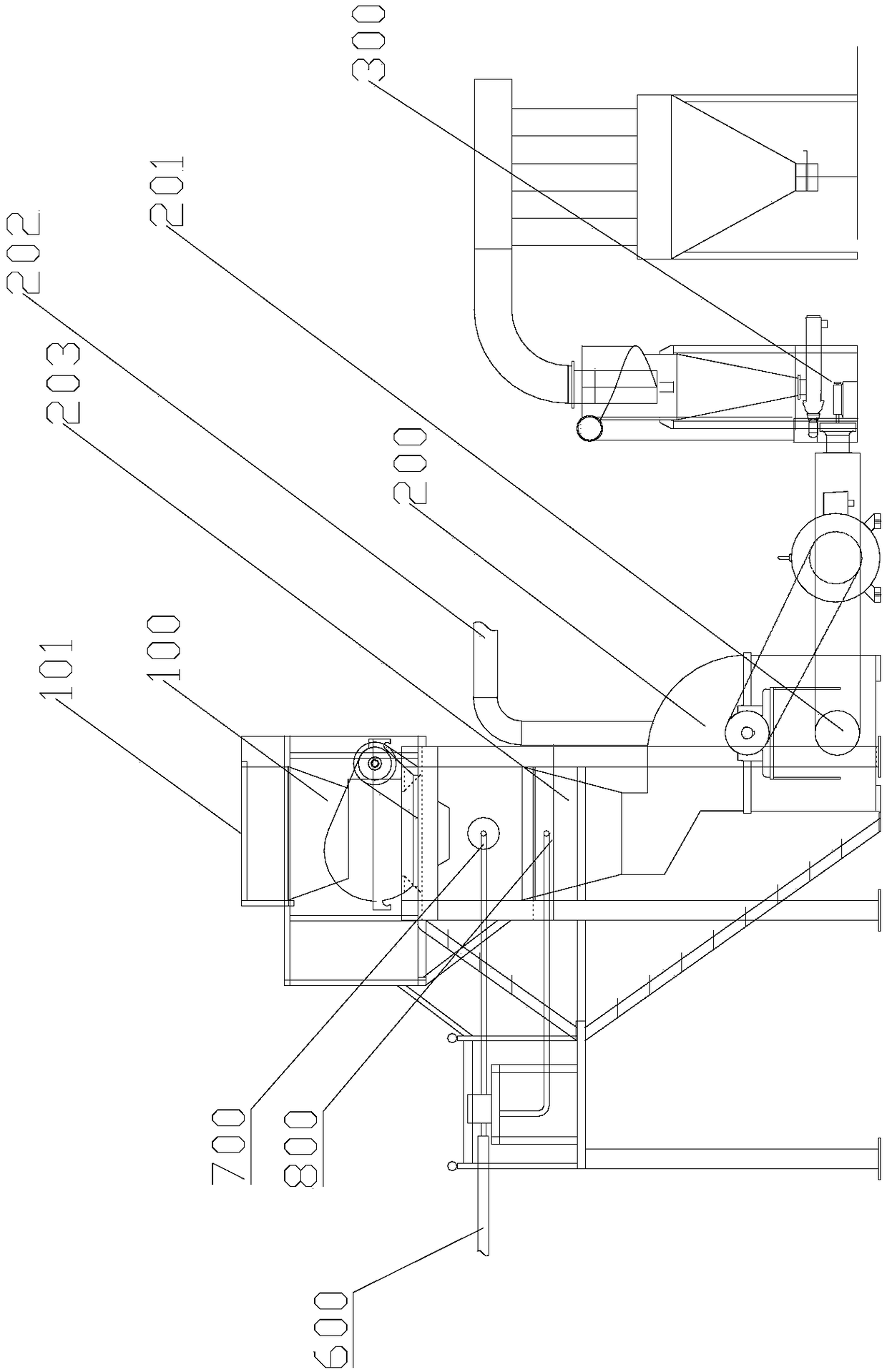

[0052] Example 1

[0053] A separation method, comprising the following steps:

[0054] S1: Add the material to the shredder for shredding;

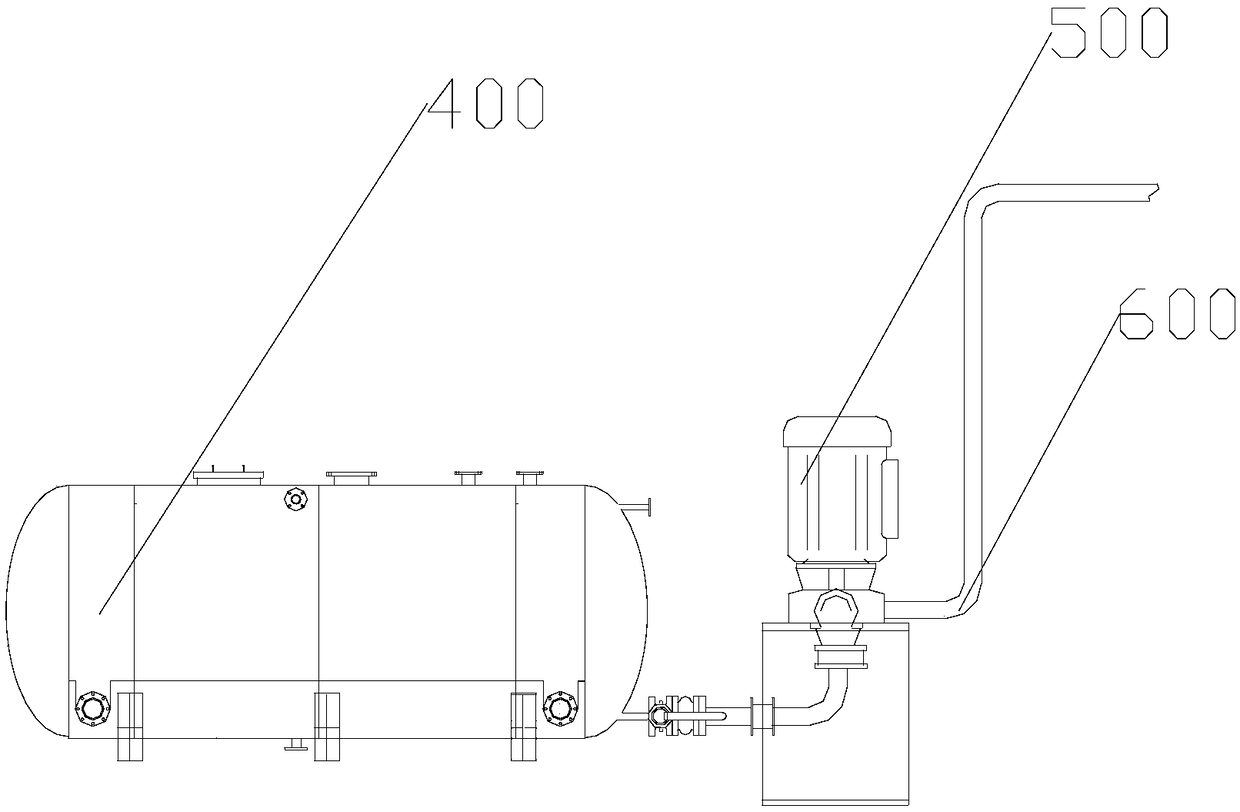

[0055] S2: Cool the shredded material;

[0056] S3: Add the cooled material to the pulverizer for pulverization; the pulverizer separates the PVC and PU in the material.

[0057] In some embodiments, the leftovers of luggage are fabrics cut out during the production of luggage, belonging to polymer materials, which are mainly divided into two layers: the inner layer is a layer of PVC (polyvinyl chloride) fabric, and the outer layer is PU (polyurethane) and other fabrics; luggage scraps are treated as materials; when the materials are separated, they are first shredded by a shredder, so that large pieces of luggage scraps are shredded into small pieces;

[0058] It cools the shredded small pieces of material, so that the PVC in the material changes hard and brittle under low temperature conditions; in this way, the PVC and PU can be se...

Example Embodiment

[0066] Embodiment 2

[0067] In addition to the above method, the method further includes step S4 : removing the dust generated by the pulverizer by using the dust collector 300 .

[0068] In the process of pulverizing materials and separating PVC and PU, dust will be generated. Using the dust collector 300 to remove the dust generated by the pulverizer is conducive to protecting the environment, improving the working environment, and avoiding dust explosion.

[0069] The separation method provided by the invention makes it easier to separate PVC and PU in the material in the pulverizer by lowering the temperature of the material, thereby improving the separation efficiency.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap