In-plane multidirectional loading fundamental frequency adjustable shake table model test shearing box

A technology of multi-directional loading and model testing, which is applied in vibration testing, testing of material strength by applying stable shear force, testing of machine/structural components, etc., can solve problems such as inability to realize multi-directional loading, and reduce the boundary effect, simple structure, and reduced boundary effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

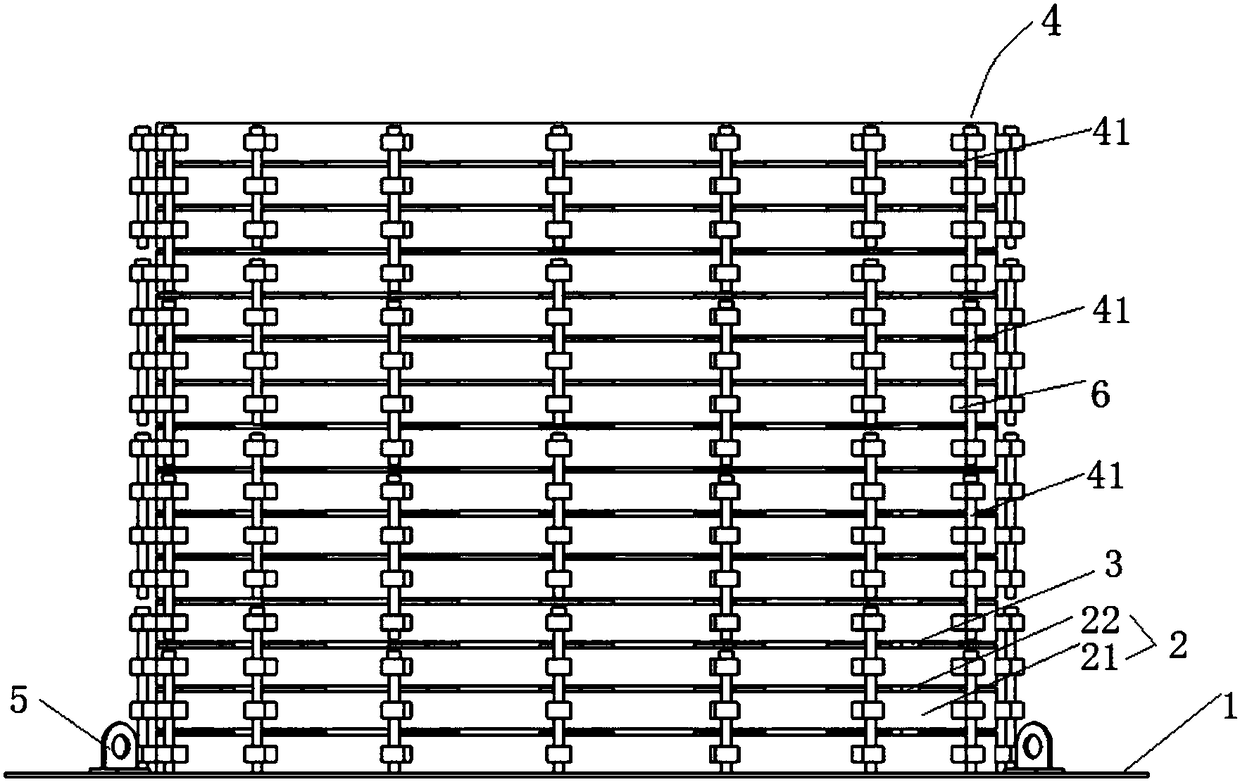

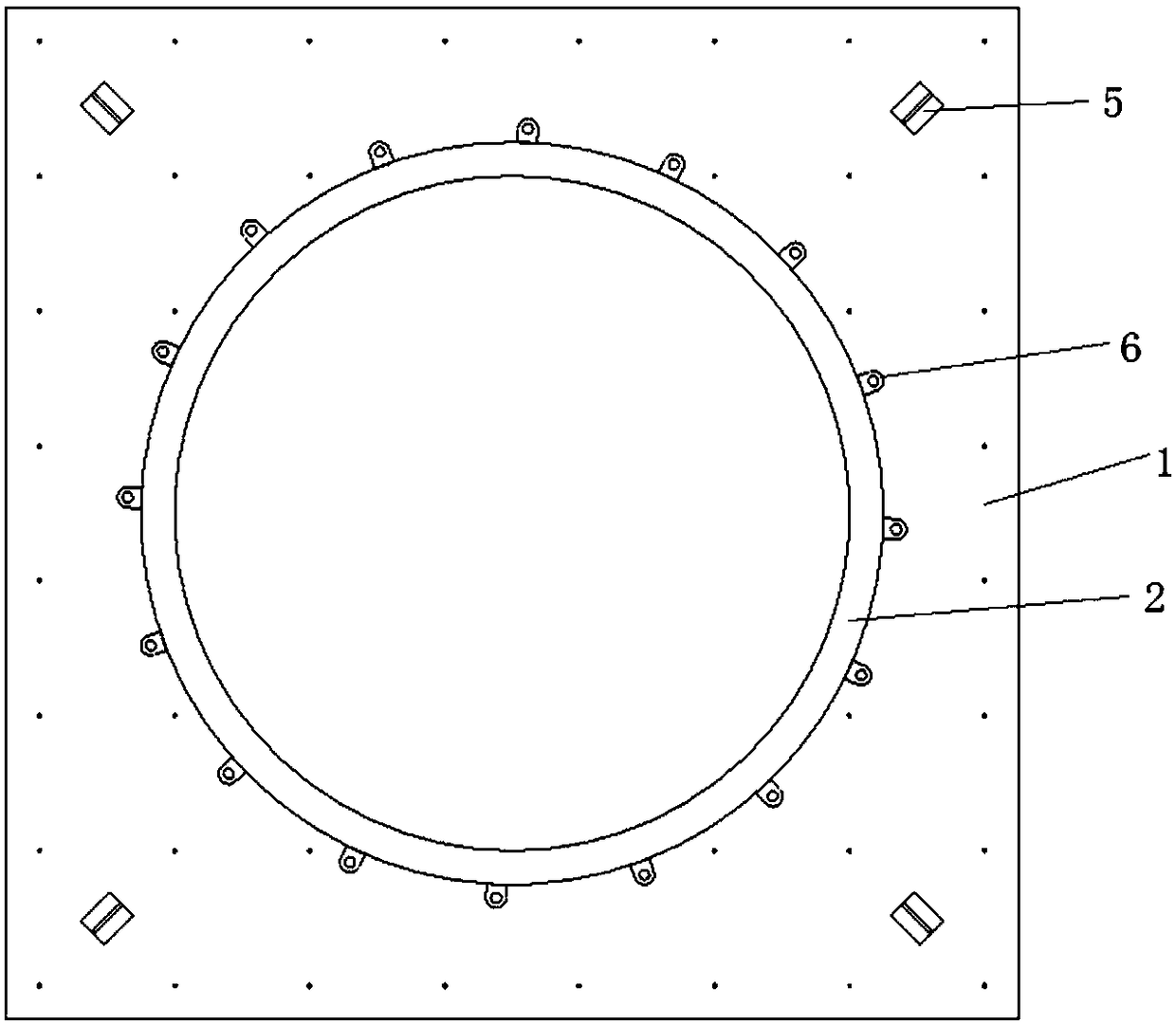

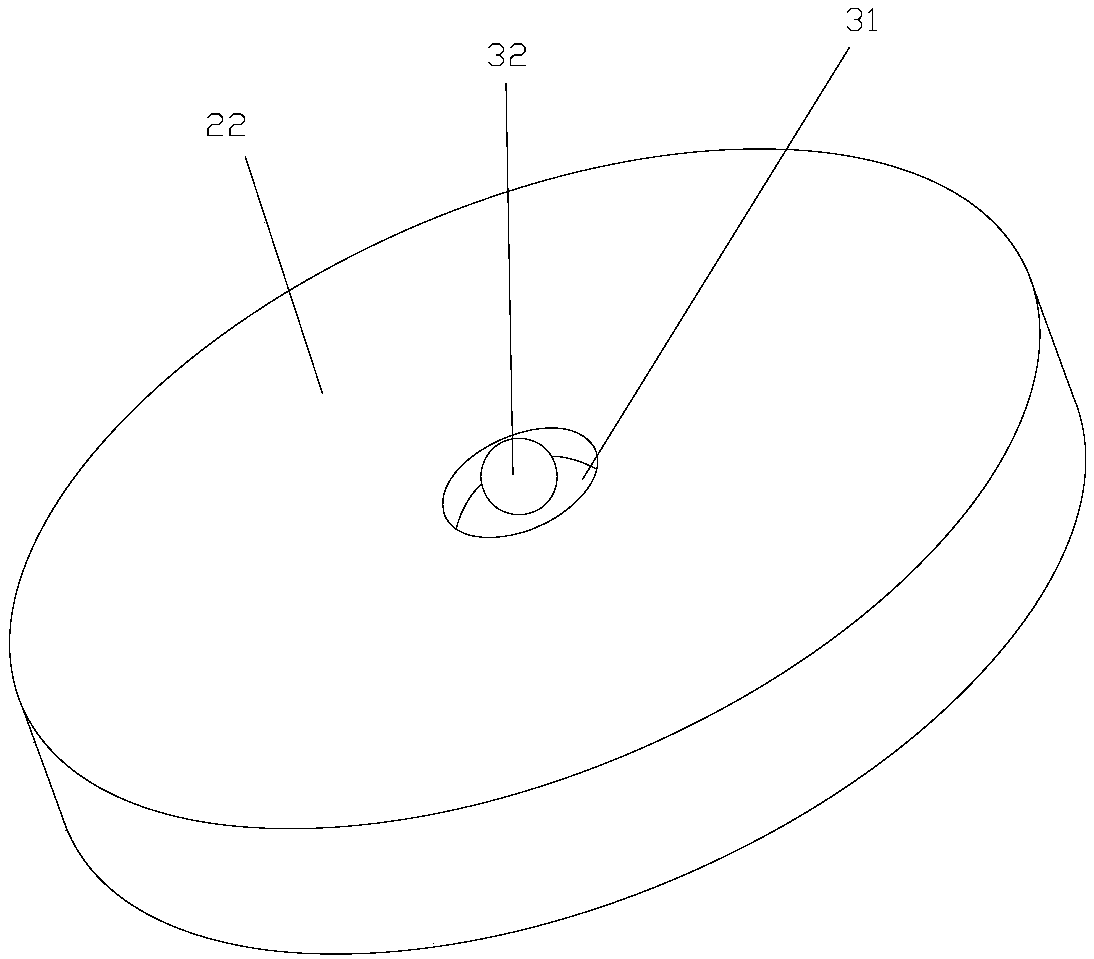

[0025] Such as Figure 1-Figure 5 As shown, the present invention provides an in-plane multi-directional adjustable fundamental frequency vibration table model test shear box, including a base 1, a box frame 2 stacked on the base 1, and a box frame 2 arranged between adjacent box frames 2. The sliding connection structure 3 between them and the stiffness adjustment device 4 connecting the box frame 2, the stiffness adjustment device 4 is evenly distributed along the circumference of the outer surface of the box frame 2, and the stiffness adjustment device 4 includes several stiffness adjustment units 41 , the stiffness adjustment units 41 are distributed along the same vertical direction, and each stiffness adjustment unit 41 is connected to an adjustable number of adjacent box frames 2 .

[0026] Such as Figure 1-Figure 3 As shown, several rings 5 for hoisting and moving the shear box are arranged symmetrically on the base 1 . The box frame 2 at the bottom is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com