Modular net belt chain and net belt system

A mesh belt chain, modular technology, applied in the field of mesh belts, can solve the problems of thin mesh belt structure, affecting product quality and production cost, easy to wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

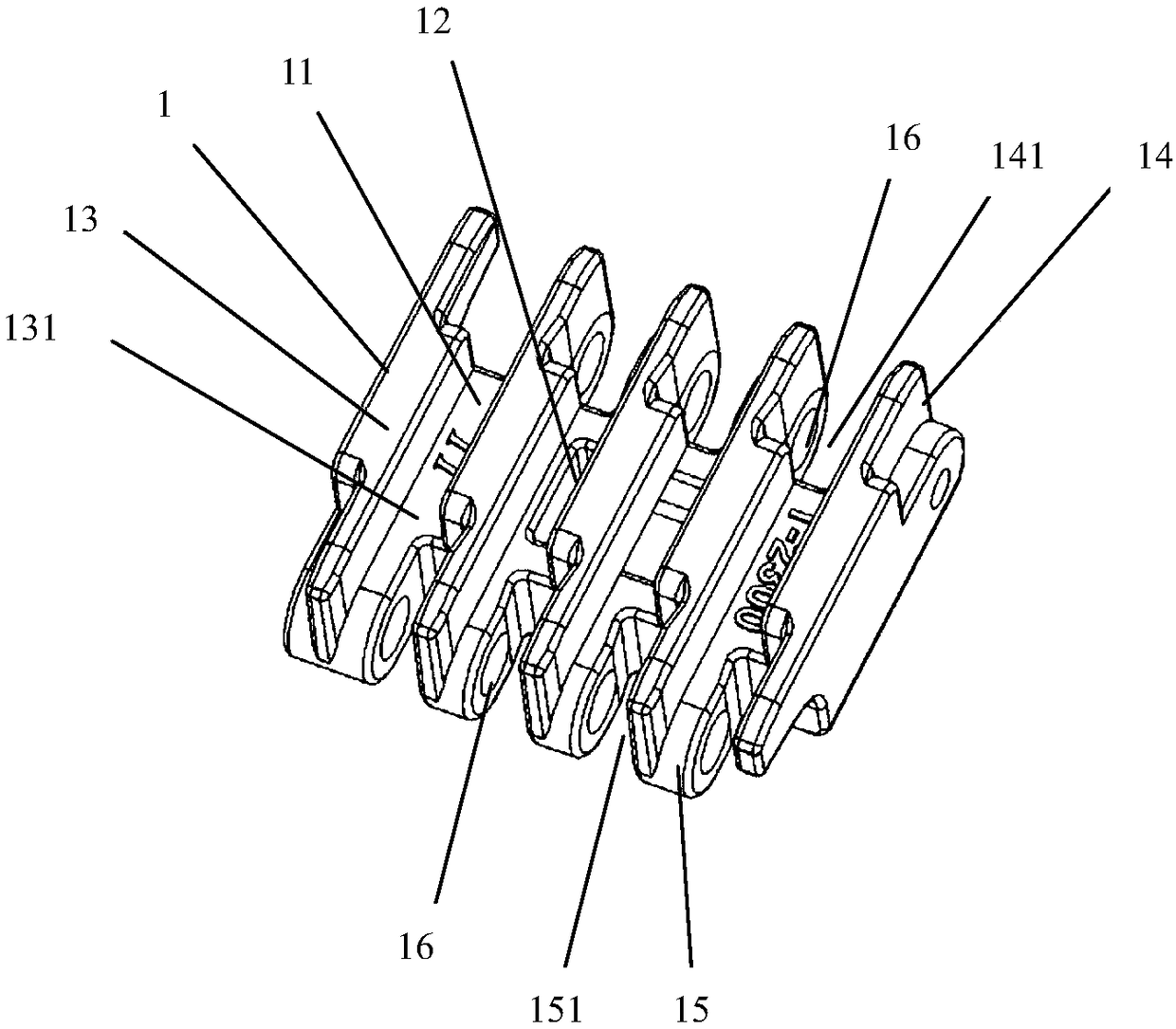

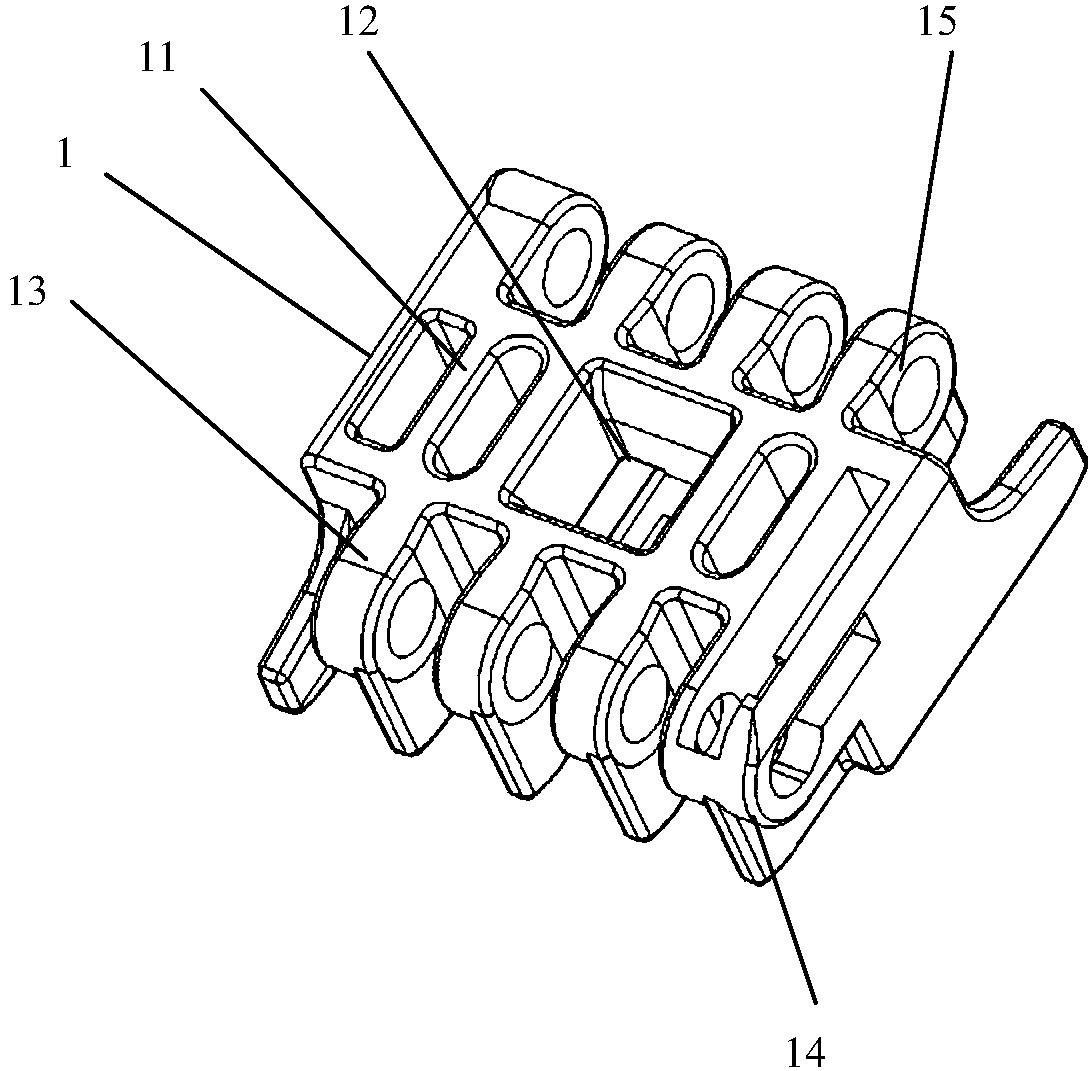

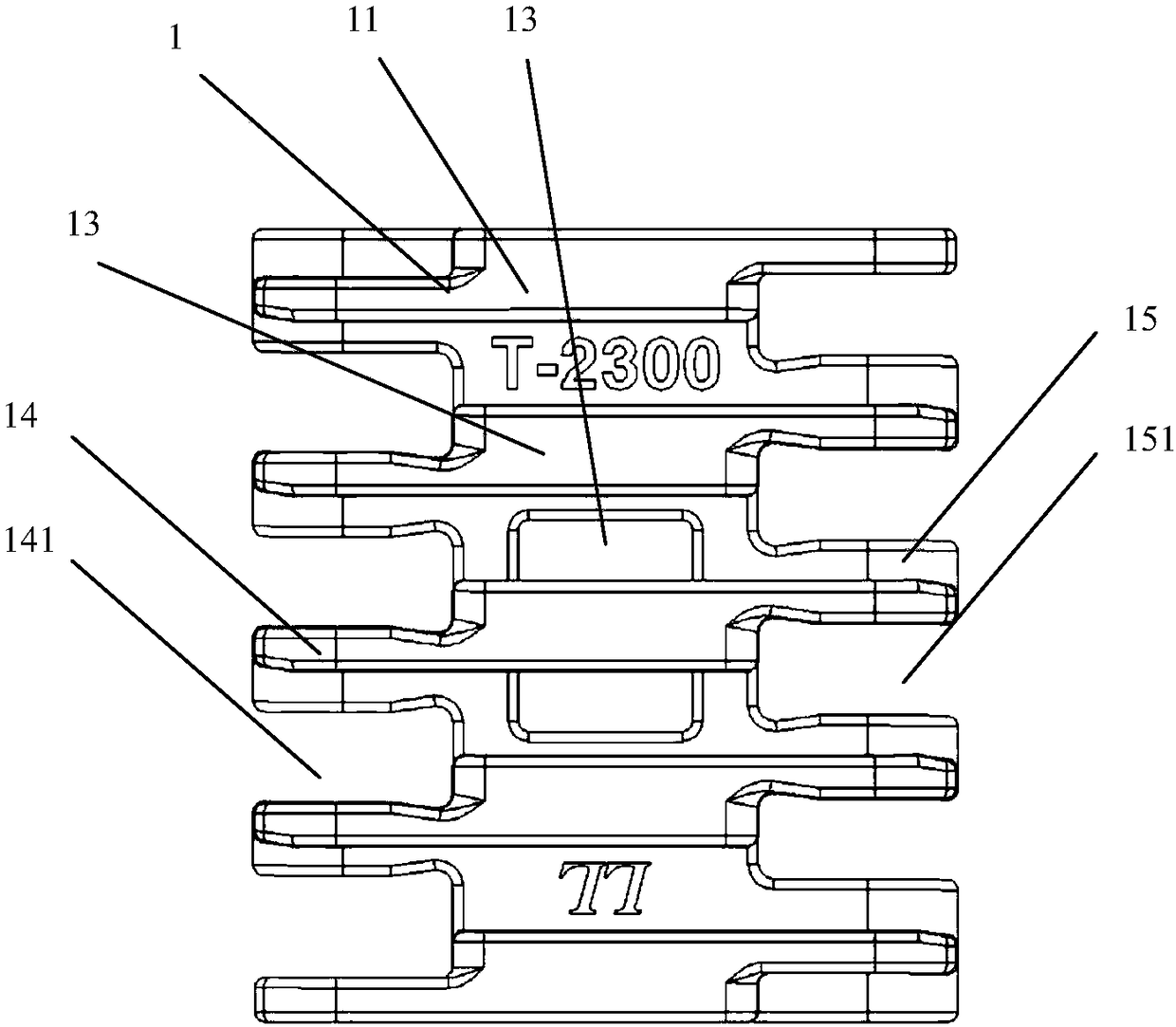

[0038] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 7 As shown, a mesh belt system of a preferred embodiment is shown, and the mesh belt system includes: a mesh belt chain 10, and also includes: a sprocket 2, and the sprocket 2 has several sprocket teeth 21, and the sprocket teeth 21 and the teeth Hole 12 matches. The mesh belt chain 10 wraps around the sprocket 2, and the movement of the mesh belt chain 10 is driven by the rotation of the sprocket 2, thereby realizing the transportation of the production line.

[0039] In a further embodiment of the present invention, the mesh belt system also includes: a transition plate 3, the transition plate 3 is horizontally fixed on one side of the sprocket 2, and one side of the transition plate 3 extends outward to form a plurality of locking teeth 31, and the plurality of locking teeth 31 is located directly above the sprocket 2, and each locking tooth 31 is matched with an upper l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com