A kind of preparation method of high-purity oxygen-free high silver-containing copper rod

A high-purity, copper rod technology is applied in the field of preparation of high-purity, oxygen-free and high-silver-containing copper rods, which can solve the problems of increasing product contact resistance, low yield, shortening material service life, etc., and achieves increased tensile strength and extension. rate, improved anti-oxidative properties, and good anti-oxidative properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

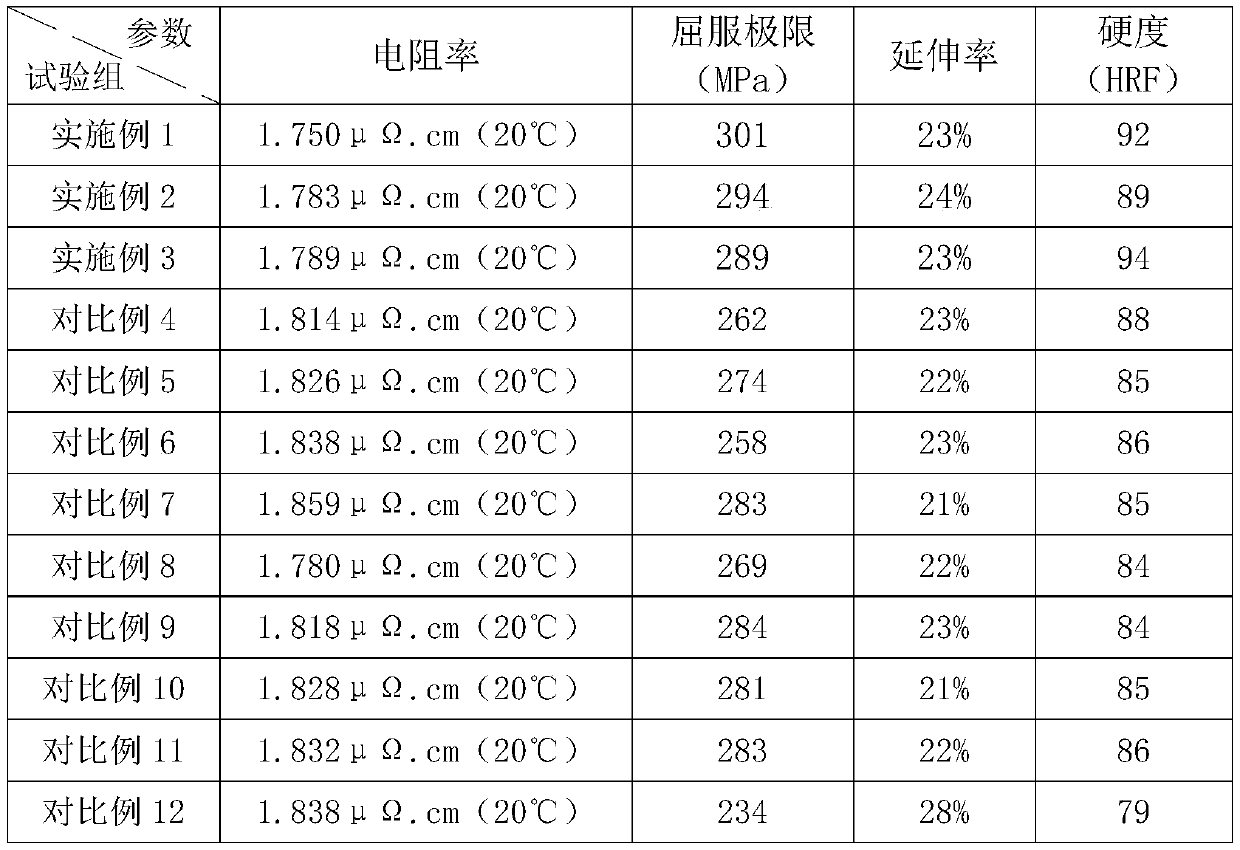

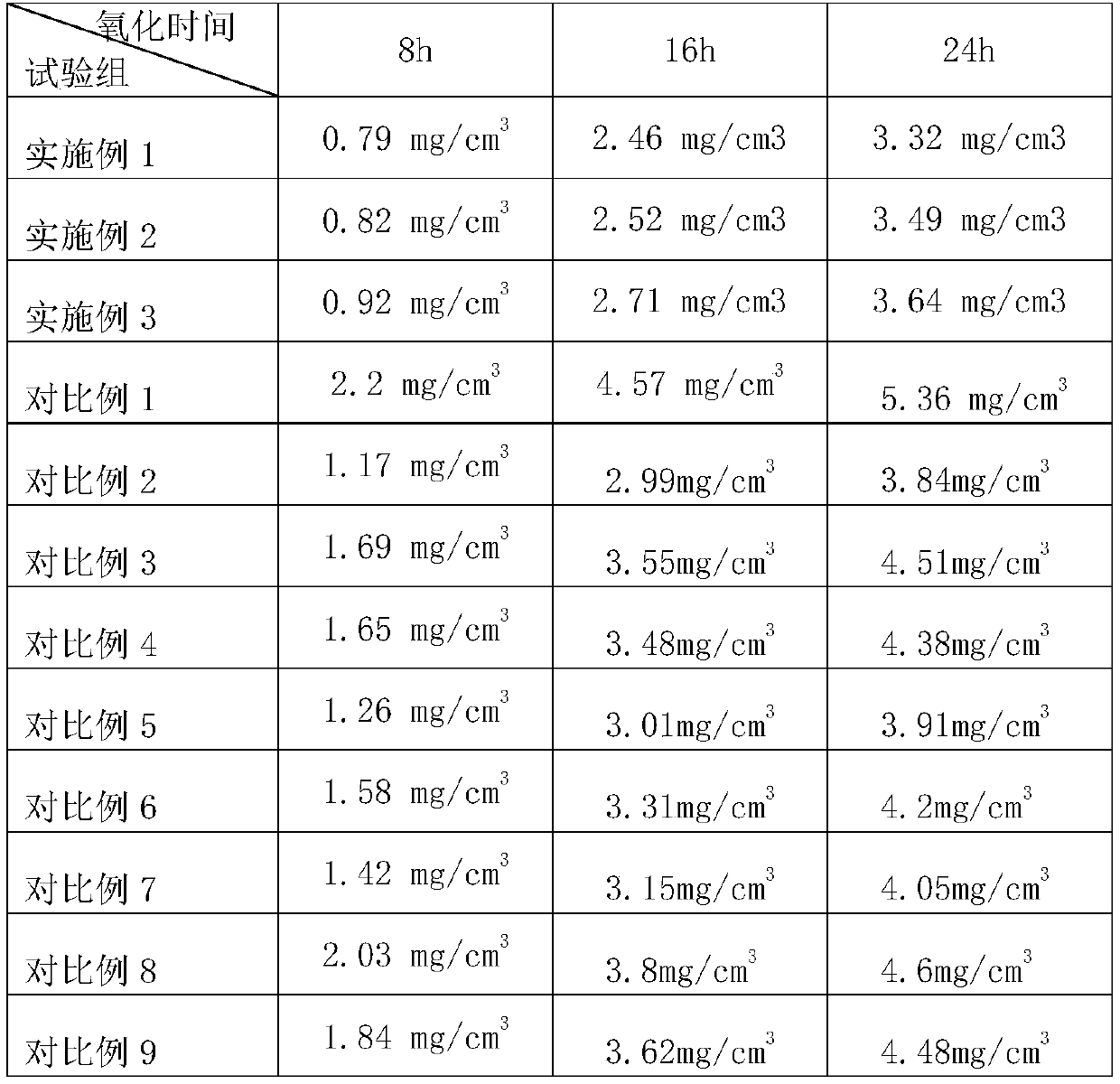

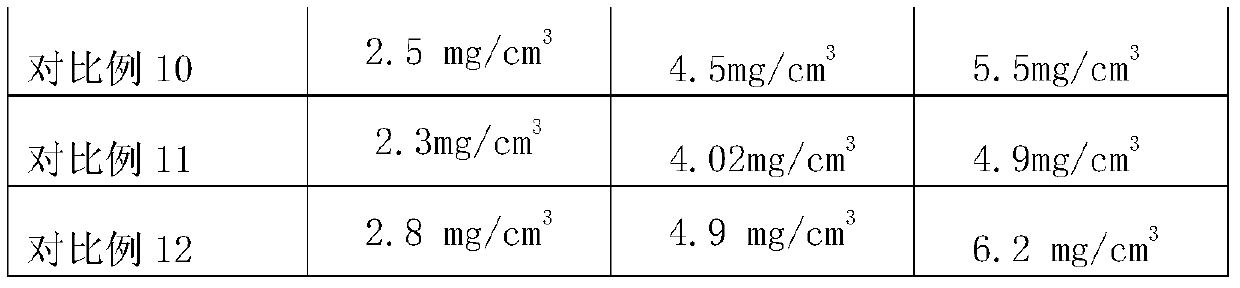

Embodiment 1

[0024] A method for preparing a high-purity oxygen-free high silver-containing copper rod is prepared by an up-drawing process, comprising the following steps:

[0025] (1) Ingredients: Prepare the raw materials in the following weight percentages: 0.009% silver, 0.018% zirconium, 0.015% chromium, and 99.958% copper, wherein silver is selected from silver ingots with a purity of 99.99%, and the resistivity of silver at 20° C. is 1.784 μΩ. cm, the copper is high-purity cathode electrolytic copper;

[0026] (2) Place the high-purity cathode electrolytic copper to be used above the uplink power frequency furnace for baking, and bake out the moisture in the electrolytic copper;

[0027] (3) Melting the raw materials in step (1) into a solution at 1288°C, adding other raw materials in step (1) for each row of electrolytic copper, so that the weight percentage of each raw material meets the requirements;

[0028] (4) In the melting step (1) raw materials are covered with graphite f...

Embodiment 2

[0032] A method for preparing a high-purity oxygen-free high silver-containing copper rod is prepared by an up-drawing process, comprising the following steps:

[0033] (1) Ingredients: Prepare the raw materials in the following weight percentages: 0.03% silver, 0.03% zirconium, 0.022% chromium, and 99.918% copper, wherein silver is selected from silver ingots with a purity of 99.99%, and the resistivity of silver at 20° C. is 1.821 μΩ. cm, the copper is high-purity cathode electrolytic copper;

[0034] (2) Place the high-purity cathode electrolytic copper to be used above the uplink power frequency furnace for baking, and bake out the moisture in the electrolytic copper;

[0035] (3) Melting the raw materials in step (1) into a solution at 1350°C, adding other raw materials in step (1) for each row of electrolytic copper, so that the weight percentage of each raw material meets the requirements;

[0036] (4) In the melting step (1) raw materials are covered with graphite fla...

Embodiment 3

[0040] A method for preparing a high-purity oxygen-free high silver-containing copper rod is prepared by an up-drawing process, comprising the following steps:

[0041](1) Ingredients: Prepare the raw materials in the following weight percentages: 0.18% silver, 0.045% zirconium, 0.029% chromium, and 99.746% copper, wherein silver is selected from silver ingots with a purity of 99.99%, and the resistivity of silver at 20° C. is 1.848 μΩ. cm, the copper is high-purity cathode electrolytic copper;

[0042] (2) Place the high-purity cathode electrolytic copper to be used above the uplink power frequency furnace for baking, and bake out the moisture in the electrolytic copper;

[0043] (3) Melting the raw materials in step (1) into a solution at 1460° C., adding other raw materials in step (1) for each row of electrolytic copper, so that the weight percentage of each raw material meets the requirements;

[0044] (4) In the melting step (1) raw materials are covered with graphite f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com