Angle-adjustable steel blade foot

A technology for adjusting angles and blade feet, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of inability to flexibly correct the posture of the box body, and cannot adjust the angle in time, and achieve low production cost, easy operation, and easy installation The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

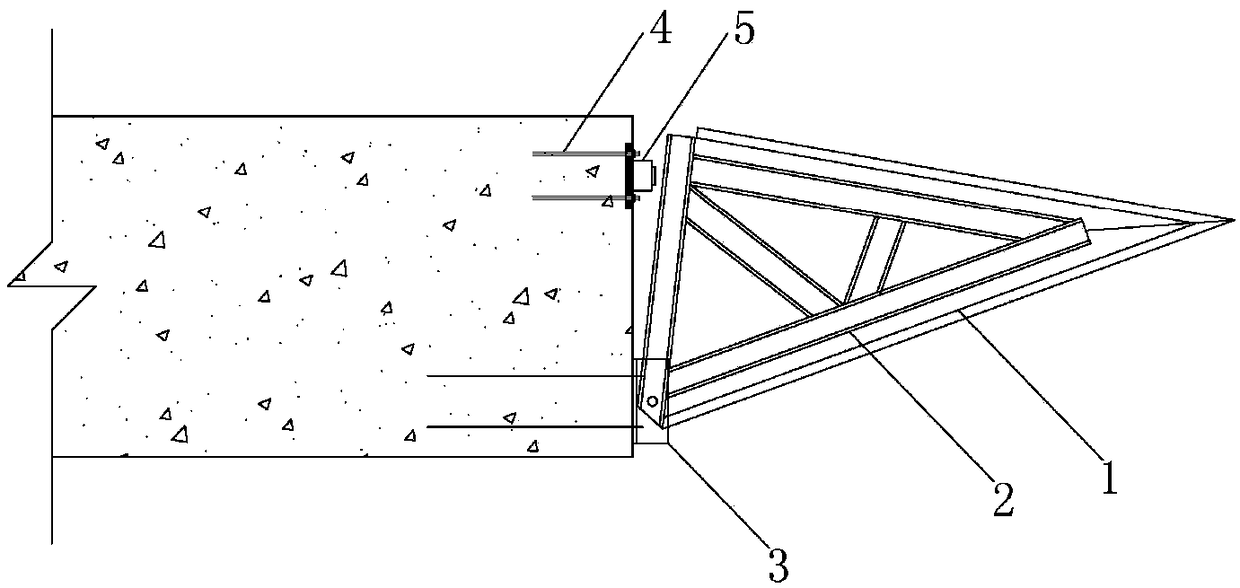

[0016] The structure of this embodiment is as figure 1 As shown, a steel blade foot device with an adjustable angle with the horizontal plane is composed of a steel blade foot 1, a steel truss 2, a fixed hinge 3, a pre-embedded flange 4, and a jack 5.

[0017] The steel blade foot 1 and the steel truss 2 are connected by welding to ensure a reliable connection between the two. The steel blade foot 1 at the bottom is used as a component for eating soil and jacking, and the steel truss 2 is used as the main force transmission component; the fixed hinge 3 is the steel truss close to The fixed nodes on the inside of the box are connected with the steel truss 2 by bolts, and the bolts can be manually adjusted;

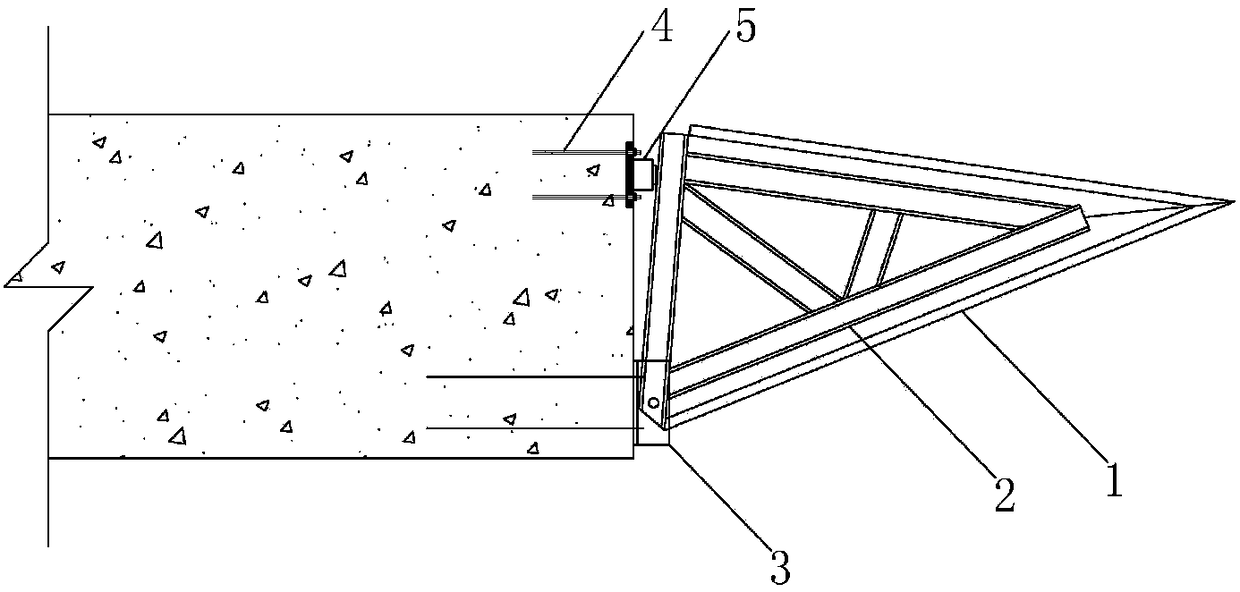

[0018] Such as figure 2 As shown, during the box culvert jacking process, the fixing hinge 3 bolts are locked; the jack 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com