A Compact Heat Pipe System for Waste Heat Utilization

A technology with compact structure and heat pipe, which is applied in the field of heat pipe, can solve the problems of uncompact structure of heat pipe waste heat utilization system, affect the heat absorption area of the evaporation end, and the small heat absorption range of the evaporation end, so as to improve the waste heat absorption capacity, compact structure, avoid The effect of local overheating or overcooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0045] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

[0046] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

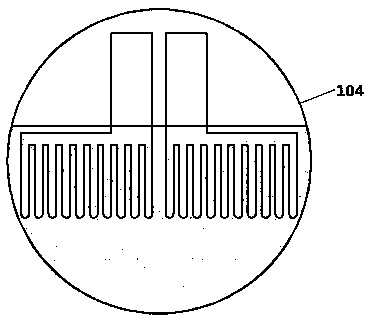

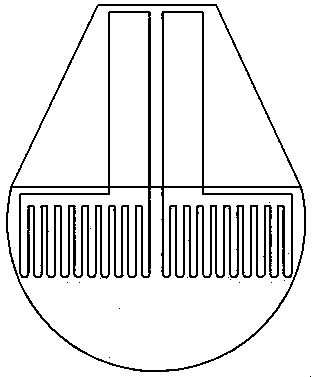

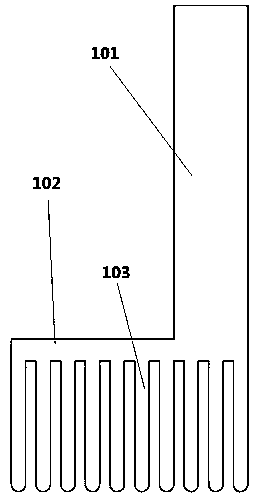

[0047] Such as Figure 1-6 As shown, a heat pipe 10 arranged in a flue and using a flue waste heat device, the heat pipe includes a vertical part 101, a horizontal part 102 and a vertical pipe 103, wherein the bottom end of the vertical part 101 communicates with the horizontal part 102, The horizontal part 102 extends from the bottom end of the vertical part 101 to a direction away from the vertical part 101, and the lower part of the horizontal part 102 communicates with a plurality of vertical pipes 103, wherein the vertical pipes 103 are the evaporation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com