Multi-layer type multi-stage array pressure sensor

A pressure sensor, multi-layer technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc., can solve the problems of high mechanical fatigue strength, low hysteresis, high spatial resolution, etc., to reduce manufacturing costs and difficulty, testing and manufacturing simplicity, and the effect of improving inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

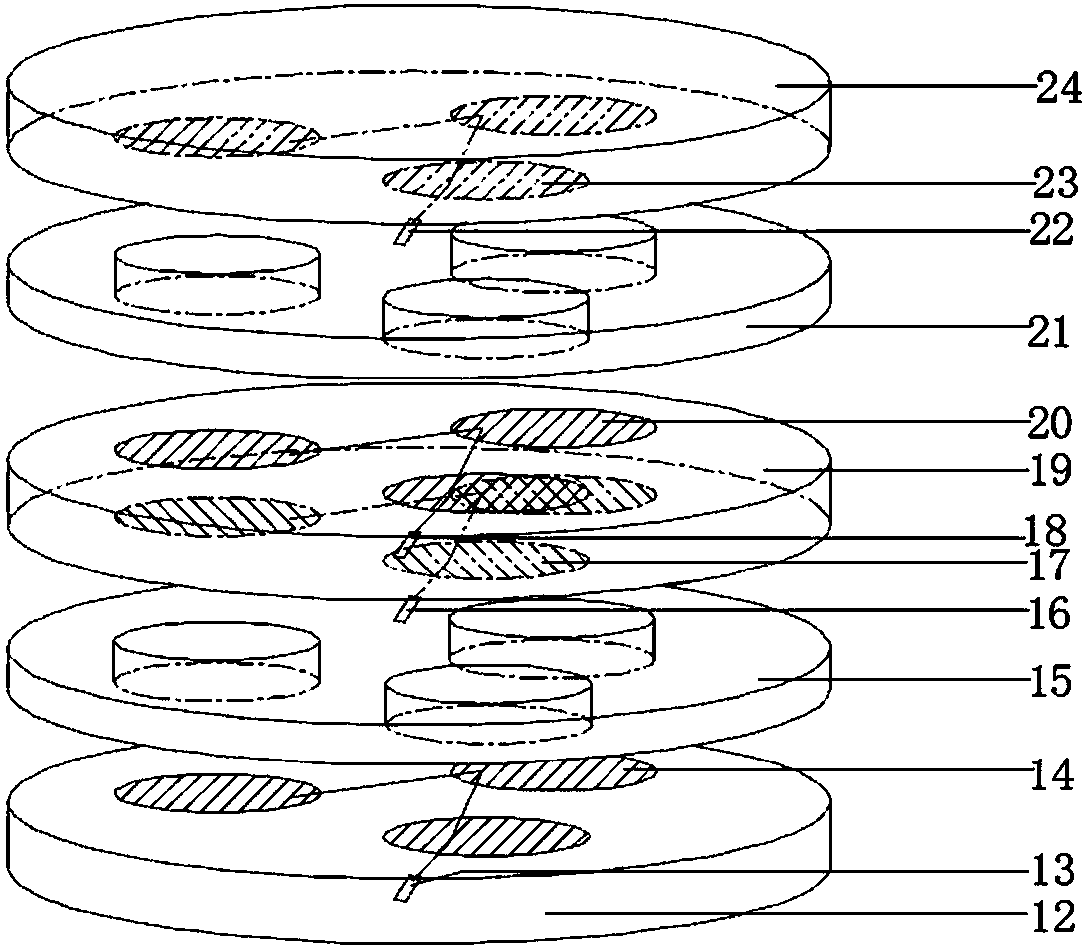

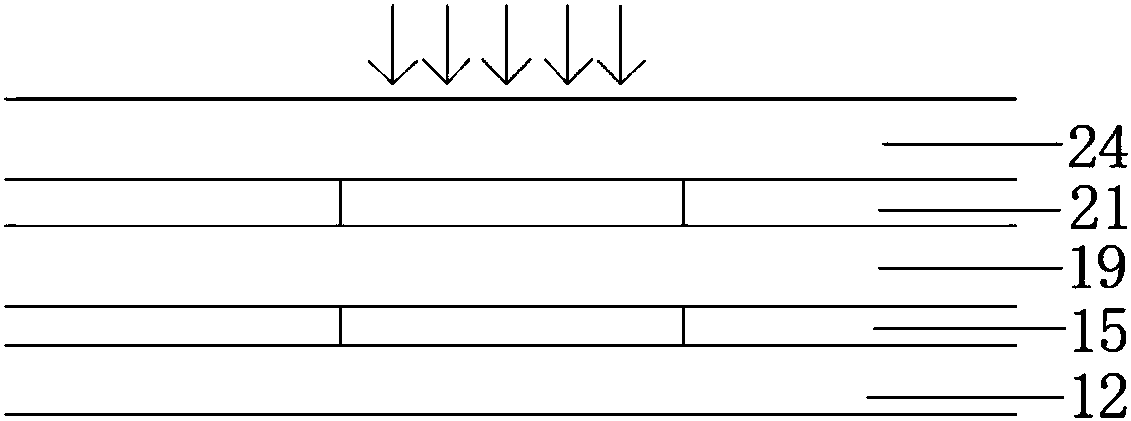

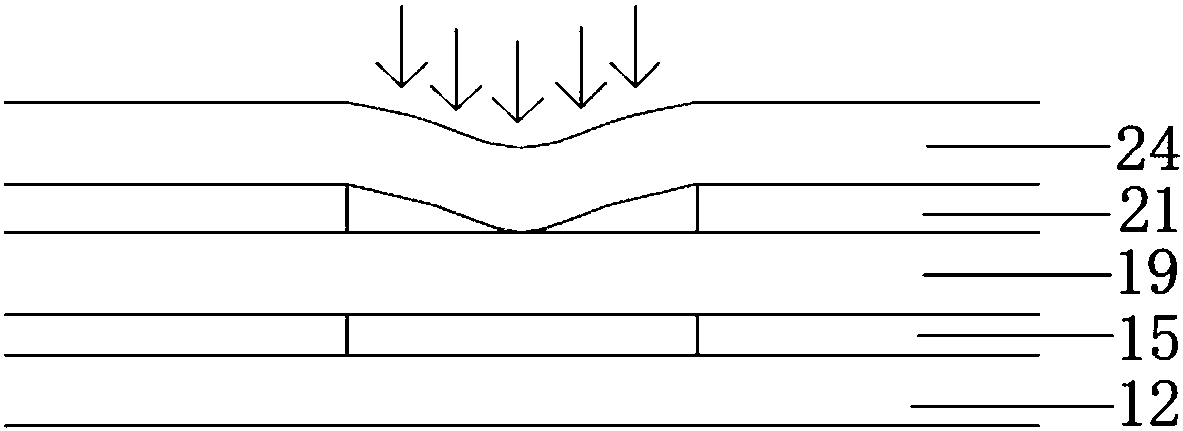

[0028] Such as figure 1 As shown, the present invention comprises a pressure sensing unit mainly composed of a bottom layer 12, a lower spacer layer 15, an intermediate layer 19, an upper spacer layer 21 and a top layer 24 which are closely laminated from bottom to top; the upper surface of the bottom layer 12 is provided with three A bottom electrode 14 uniformly distributed along the circumferential direction, three through holes corresponding to the positions of the three bottom electrodes 14 are provided in the lower spacer layer 15 and the upper spacer layer 21, and the lower surface of the middle layer 19 is provided with the three through holes respectively. Three intermediate layer lower electrodes 17 corresponding to the positions of the bottom electrodes 14, the upper surface of the intermediate layer 19 is provided with three intermediate layer upper electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com