Process system and method for demulsification of oil-emulsion-containing sewage

A process system and emulsion technology, applied in separation methods, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of complex production process of demulsifier, difficulty in degrading demulsifier, high cost of demulsifier, and achieve economic benefits and environmental benefits, reduce pollution, and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

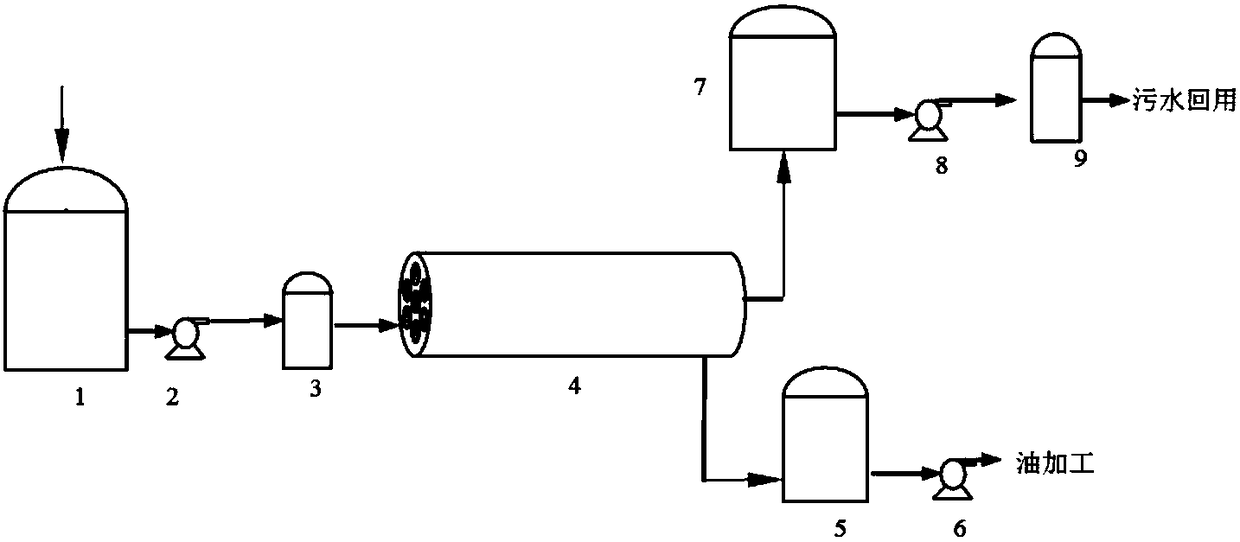

[0023] A process system for demulsifying oil-containing emulsion sewage as shown in the figure includes an emulsion sewage tank 1, a polytetrafluoroethylene tubular ultrafiltration membrane device 4, an oil phase recovery tank 5, and a water phase recovery tank 7. The above-mentioned emulsion sewage tank 1 is connected with the security filter 3 and the polytetrafluoroethylene tubular ultrafiltration membrane device 4 pipelines in turn through the material pump 2, and the polytetrafluoroethylene tubular ultrafiltration membrane device 4 is recovered with the oil phase respectively The tank 5 is connected to the water phase recovery tank 7; the oil phase recovery tank 5 processes the recovered oil through the oil pump 6; the water phase recovery tank 7 enters the activated carbon filter 9 through the water pump 8 for sewage reuse; The pore diameter of the security filter 3 is 5 μm; the polytetrafluoroethylene tubular ultrafiltration membrane device 4 is an internal pressure tubu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com