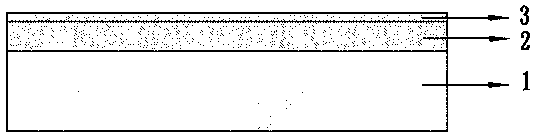

TiAl based alloy type thermal barrier coating and preparation method thereof

A thermal barrier coating and base alloy technology, applied in metal material coating process, coating, superimposed layer plating and other directions, can solve problems such as reducing room temperature processing ability, improve the ability to resist easy sintering, ensure high temperature performance, the effect of improving high temperature strength and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

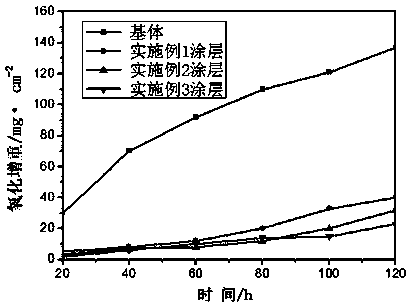

Examples

Embodiment 1

[0025] The composition of the TiAl-based alloy is (wt.%): 43Ti, 49Al, 0.3Si, 4.2Mo, 3Nb, 0.5Ni, and the size is 100mm×20mm×10mm. Sanding the substrate and 220 grit Al 2 o 3 Sandblasting, then cleaning with ethanol, and then place the annealing furnace to preheat to 50°C.

[0026] The composition of the cladding material (MCrAlY+Ti+Nb+Zr) is (wt.%): 32Co, 38Cr, 18Ti, 10Al, 0.8Y, 0.2Si, 0.5Nb, 0.5Zr.

[0027] Place the preheated TiAl-based alloy in a GS-TFL6000 CO 2 The laser cladding processing area of the laser uses the GS-TFL synchronous powder feeder to convey the cladding material synchronously. The process parameters of laser cladding are as follows: defocus (the vertical distance from the cladding surface of the substrate to the focus of the beam) is 60mm, the spot diameter is about 4mm, the protective gas is argon, and the argon flow rate is 25L h -1 , the laser power is 4kW, and the scanning speed is 360mm·min -1 , synchronous powder feeding rate 100g·min -1 . ...

Embodiment 2

[0034] The composition of the TiAl-based alloy is (wt.%): 45Ti, 47Al, 0.2Si, 5.5Mo, 2Nb, 0.3Co, and the size is 100mm×20mm×10mm. Sanding the substrate and 220 grit Al 2 o 3 Sand blasting, then cleaning with ethanol, and then place the annealing furnace to preheat to 100°C.

[0035] The composition of the cladding material (MCrAlY+Ti+Nb+Zr) is (wt.%): 38Ni, 40Cr, 10Ti, 8Al, 0.7Y, 1.8Si, 0.6Nb, 0.9Zr.

[0036] Place the preheated TiAl-based alloy in a GS-TFL6000 CO 2 The laser cladding processing area of the laser uses the GS-TFL synchronous powder feeder to transport the cladding material synchronously. The process parameters of laser cladding are as follows: the defocus amount is 60mm, the spot diameter is about 4mm, the protective gas is argon, and the argon flow rate is 25L h -1 , the laser power is 4kW, and the scanning speed is 360mm·min -1 , synchronous powder feeding rate 100g·min -1 .

[0037] The obtained cladding layer is machined, and the cladding surface is...

Embodiment 3

[0043] The composition of the TiAl-based alloy is (wt.%): 44Ti, 50Al, 0.1Si, 3.9Mo, 1.8Nb, 0.2Co, and the size is 100mm×20mm×10mm. Sanding the substrate and 220 grit Al 2 o 3 Sand blasting, then cleaning with ethanol, and then place the annealing furnace to preheat to 200°C.

[0044] The composition of the cladding material (MCrAlY+Ti+Nb+Zr) is (wt.%): 15Co+15Ni, 47Cr, 15Ti, 5Al, 0.1Y, 1.2Si, 0.9Nb, 0.8Zr, and the size is controlled at about 50nm.

[0045] Place the preheated TiAl-based alloy in a GS-TFL6000 CO 2 The laser cladding processing area of the laser uses the GS-TFL synchronous powder feeder to transport the cladding material synchronously. The process parameters of laser cladding are as follows: the defocus amount is 60mm, the spot diameter is about 4mm, the protective gas is argon, and the argon flow rate is 25L h -1 , the laser power is 4kW, and the scanning speed is 360mm·min -1 , synchronous powder feeding rate 100g·min -1 .

[0046] The obtained claddi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com