A kind of imitation stone plate and its manufacturing process

A technology of imitating stone and plate, applied in the field of building materials, can solve the problems of difficult to cover protrusions, difficult to achieve leveling, poor surface flatness, etc., to achieve the effect of improving surface flatness, improving efficiency and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

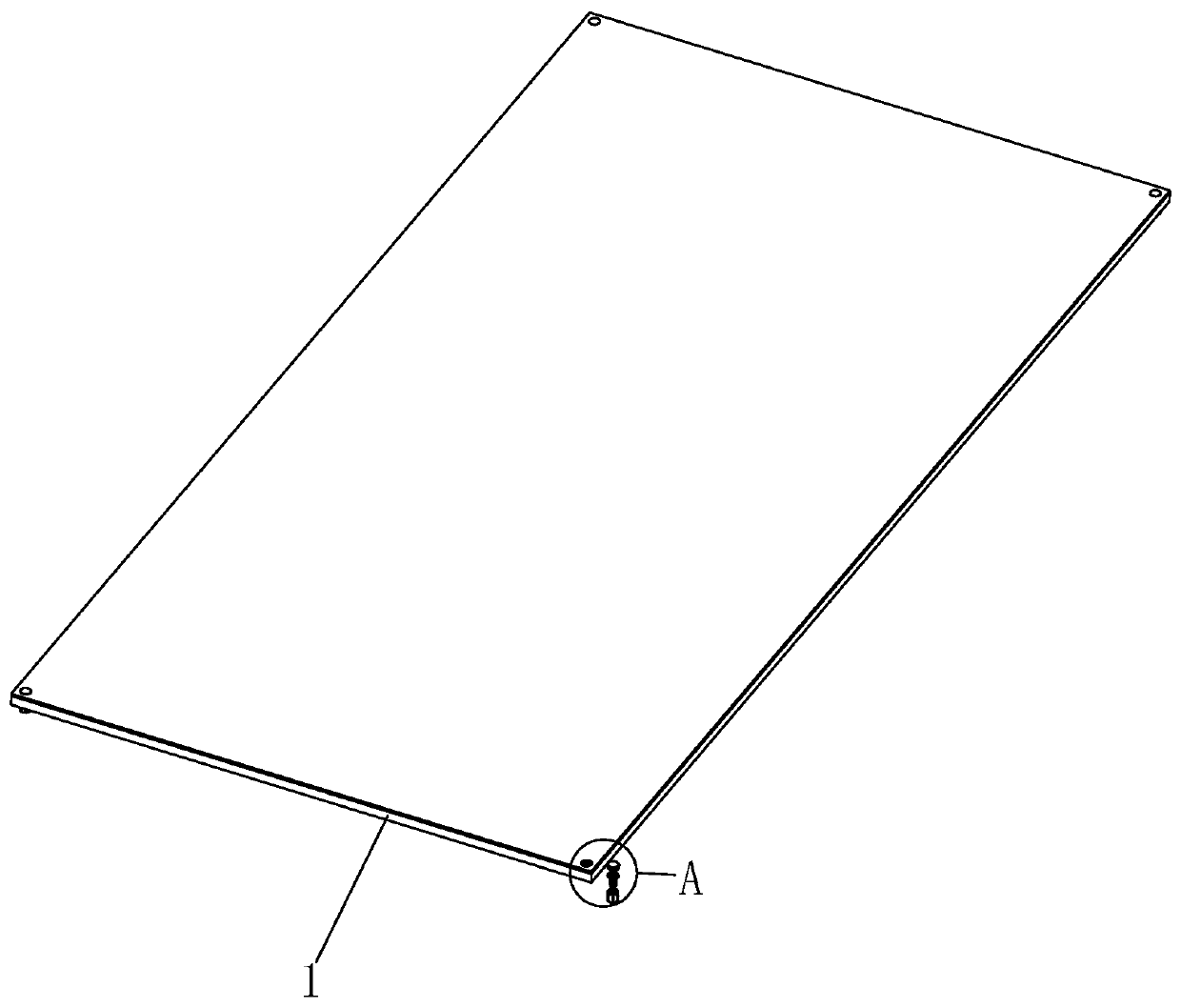

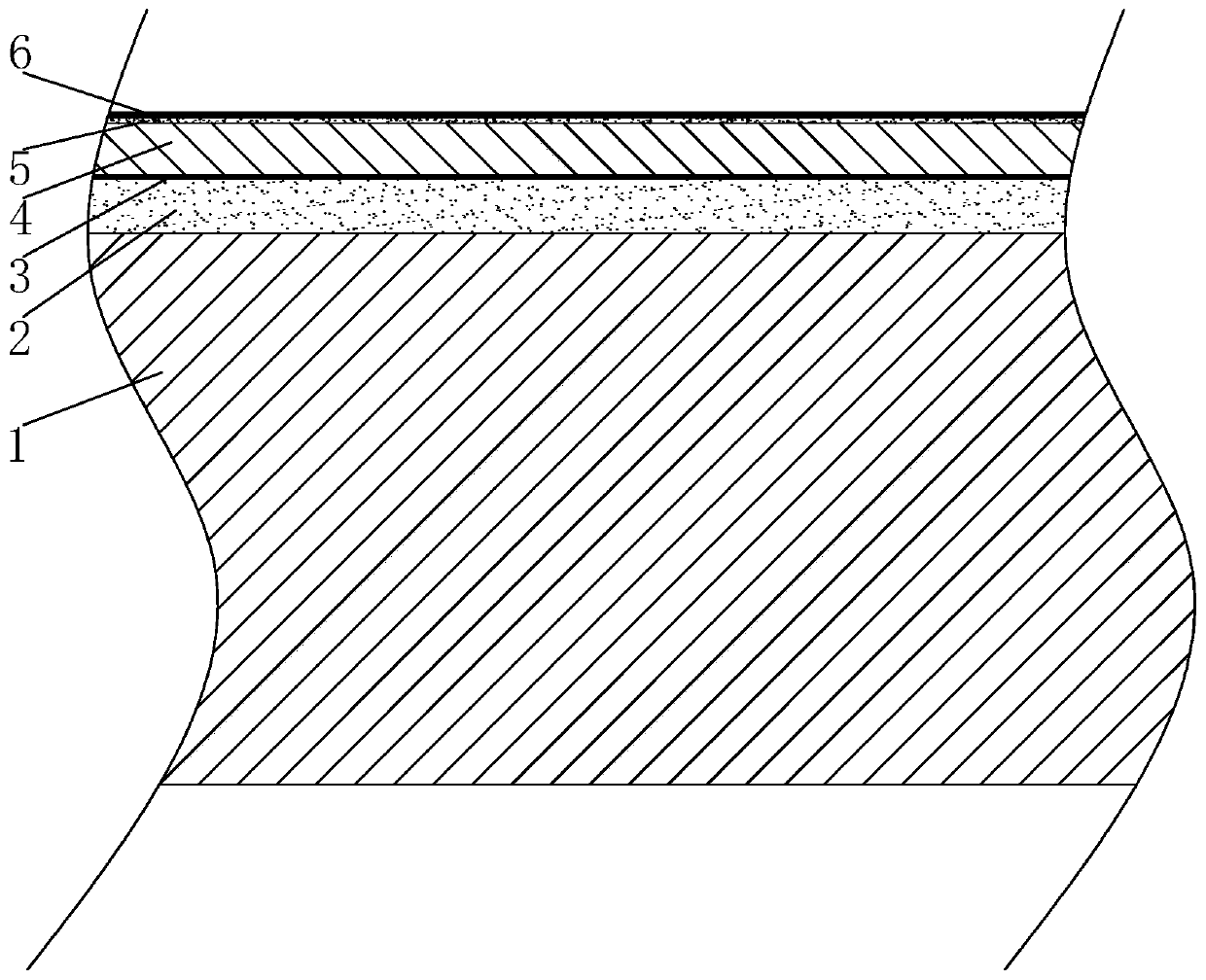

[0040] Embodiment 1: a kind of imitation stone plate, as figure 1 with figure 2 As shown, it includes a substrate 1 , a flexible anti-crack putty layer 2 coated on the upper surface of the substrate 1 , an alkali-resistant sealing primer layer 3 , an intermediate coating layer 4 , a stone-like pattern layer 5 , and a finishing layer 6 .

[0041] Such as figure 1 As shown, the substrate 1 is composed of any one of high-strength fiber cement board, metal board, PVC board, organic insulation board, and inorganic insulation board.

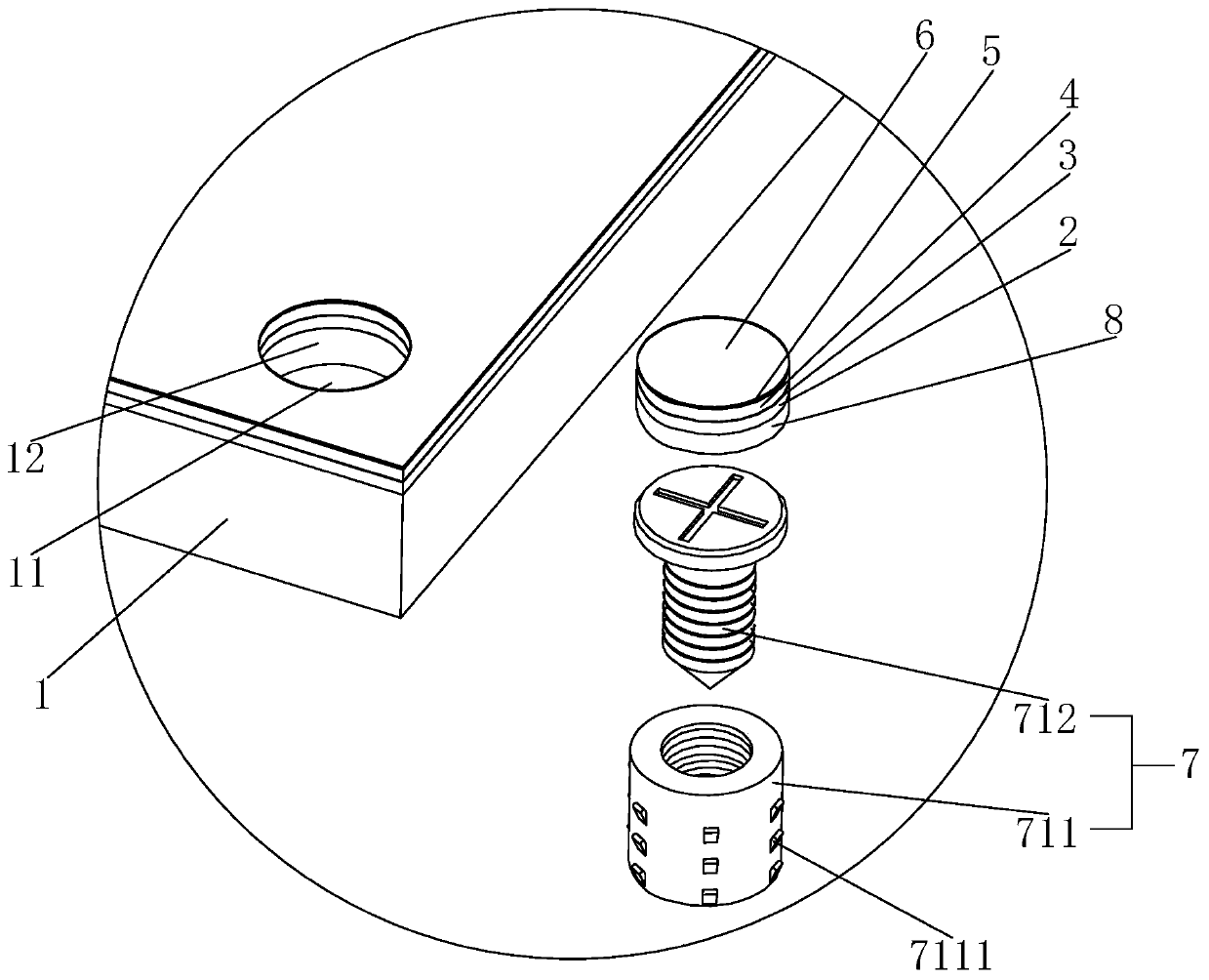

[0042] Such as figure 1 with image 3 As shown, an installation mechanism 7 for installing the base plate 1 on the wall is also included, and the installation mechanism 7 includes a fixing column 711 and a Phillips countersunk head screw 712 . The substrate 1 is square, and countersunk holes 11 are provided at the four corners of the upper surface of the substrate 1; the cross countersunk screws 712 can be completely embedded in the countersunk ho...

Embodiment 2

[0045] Embodiment 2: a kind of imitation stone plate, as Figure 4 with Figure 5 As shown, the difference from Example 1 is that the substrate 1 is made of any one of high-strength fiber cement board, metal plate, PVC board, organic insulation board, and inorganic insulation board, combined with non-woven fabrics, glass fiber cloth, Any kind of composite structure in the wire mesh, here the substrate 1 is selected to be composed of high-strength fiber cement board and glass fiber cloth. At this time, the substrate 1 not only has good strength, but also has good heat resistance and insulation Wait. At the same time, the mounting mechanism 7 used to fix the substrate 1 on the wall is different, and the counterbore 11 is not provided on the surface of the substrate 1 (see image 3 ).

[0046] Such as Figure 4 with Figure 5 As shown, there are slots 13 on both side walls of the substrate 1 , and the installation mechanism 7 includes connecting pieces 721 and bolts 722 . T...

Embodiment 3

[0048] Embodiment 3: a kind of imitation stone plate, as Image 6 As shown, the difference from Example 1 is that the substrate 1 in the imitation stone slab is made of any one of non-woven fabric, glass fiber cloth, and wire mesh; and the method used to fix the substrate 1 on the wall The mounting mechanism 7 is different.

[0049] The installation mechanism 7 includes a plurality of gun nails 731 for nailing the edge of the base plate 1 to the wall. And when installing the substrate 1 , the substrate 1 is first adhered to the wall by glue, and then the edge of the substrate 1 is fixed on the wall by gun nails 731 . At the same time, when a plurality of imitation stone panels are installed on the wall, a sealant layer 9 is formed after coating silicone sealants at the edges of a plurality of adjacent substrates 1, and the sealant layer 9 covers the guns at the edges of the substrates 1. Nail 731.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com