Fixing structure for door sheet and glass and door

A technology for fixing structure and glass, applied in the field of doors and windows, can solve the problems of low safety, glass falling off, difficult to disassemble, etc., and achieve the effect of improving assembly efficiency, meeting use requirements, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

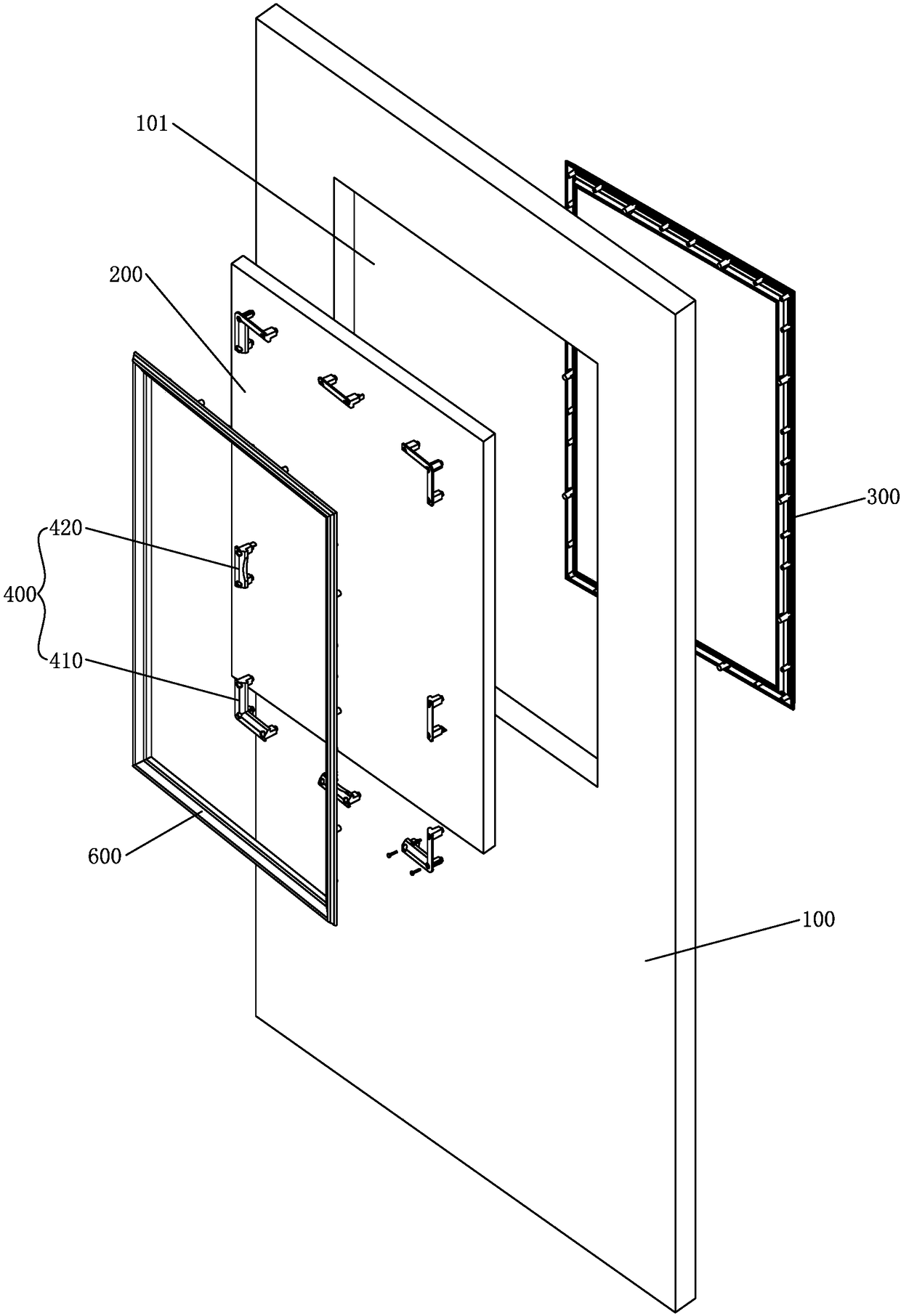

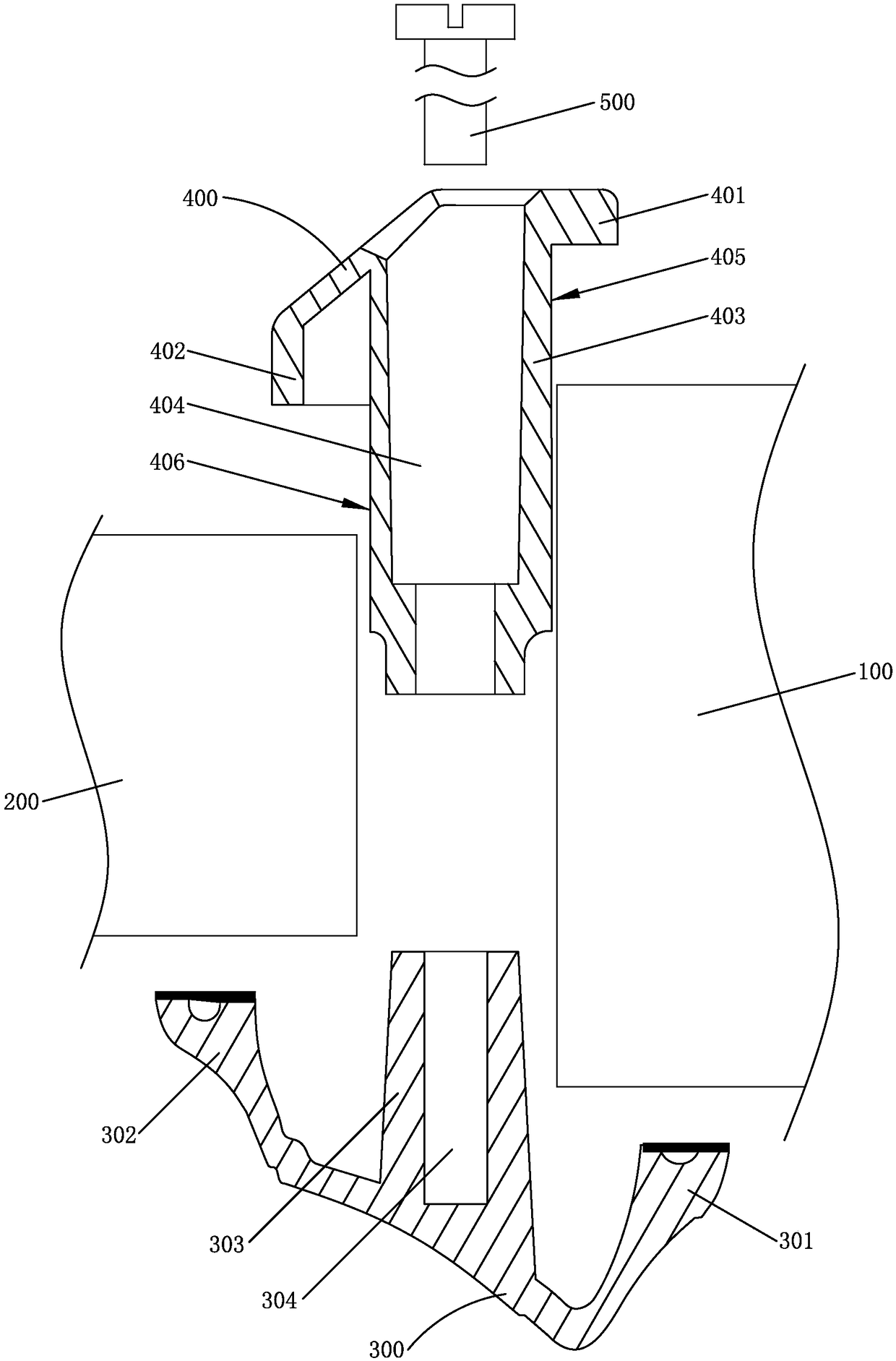

[0039] Such as figure 1 , figure 2As shown, the fixing structure for door panel and glass provided by Embodiment 1 of the present invention includes a first press frame 300 and a fixing member 400, and the outer circumference of the first press frame and the outside of the fixing member respectively contact the two planes of the door panel 100 , the inner circumference of the first press frame and the inner side of the fixing member respectively contact the two planes of the glass 200, and the fixing member is connected to the first press frame to fix the glass on the door panel.

[0040] The fixing part and the first pressure frame make the glass completely limit relative to the door panel from two opposite planes, so that the glass is fixed on the door panel. The structure of the fixing structure is simple, it is convenient to install the glass on the door panel, and there is no need to process the door panel or the glass during installation, which is beneficial to improve...

Embodiment 2

[0065] Such as Figure 11 As shown, the difference between Embodiment 2 of the present invention and Embodiment 1 above is that, in order to improve the aesthetics of installing the glass 200 on the door panel 100, the fixing structure further includes a second pressure frame arranged on the same side as the fixing member 400 600. Connect the second pressure frame to the fixing member. The second pressure frame can be used to cover the fixing part, and can also be used to cover the gap between the door panel and the glass, which is beneficial to improving the overall appearance of the door.

[0066] In this embodiment, in order to simplify the integral components of the fixing structure, the structure of the second pressure frame 600 is the same as that of the first pressure frame 300, that is, the outer periphery of the second pressure frame is provided with a second outer pressure arm for pressing the door panel 100 601, the inner periphery of the second pressure frame is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com