Light-guide capillary photometer

A technology of capillary and photometer, which is applied in the field of photometer, can solve the problems of large reflection loss of metal surface, large reflection loss of light beam, and difficult injection of liquid to be tested, etc., and achieves the reduction of reflection loss, enhanced constraint ability, and convenient optical path size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0038] Example 1

[0039] The second light reflecting device 8 is provided with an outlet for detecting light 6, and the detecting light 6 transmitted from the light guiding capillary 1 is incident on the light detector 5 through the outlet. The apertures of the probe light entrance on the first reflector 7 and the probe light exit on the second reflector 8 are adjustable. By adjusting the aperture size, the number of times the probe light 6 emitted by the light source 4 is reflected on the two reflectors can be adjusted. The aperture of the entrance on the first reflector 7 is 0.001-10mm, preferably, the aperture of the through hole is 0.005-1mm, and the aperture of the exit on the second reflector 8 is 0.001-10mm, preferably, the aperture of the through hole is 0.05 ~1mm.

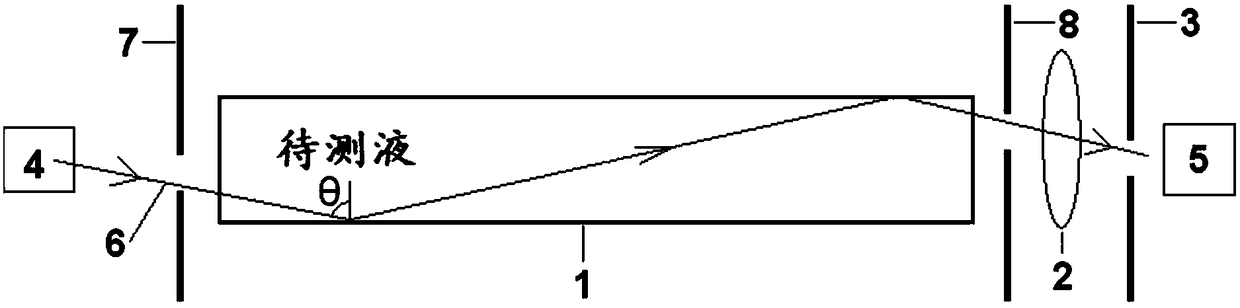

[0040] Such as figure 1 As shown, a stainless steel capillary with a polished inner wall with an inner diameter of 1.0 mm is used as a light guide capillary 1.

[0041] When the detection light 6 emitted by th...

Example Embodiment

[0045] Example 2

[0046] The second light reflecting device 8 is a plane structure with a complete surface, and the test sample generates fluorescence 9 under the excitation of the detection light, and the fluorescence 9 is incident on the photodetector 5 through the second light reflecting device 8.

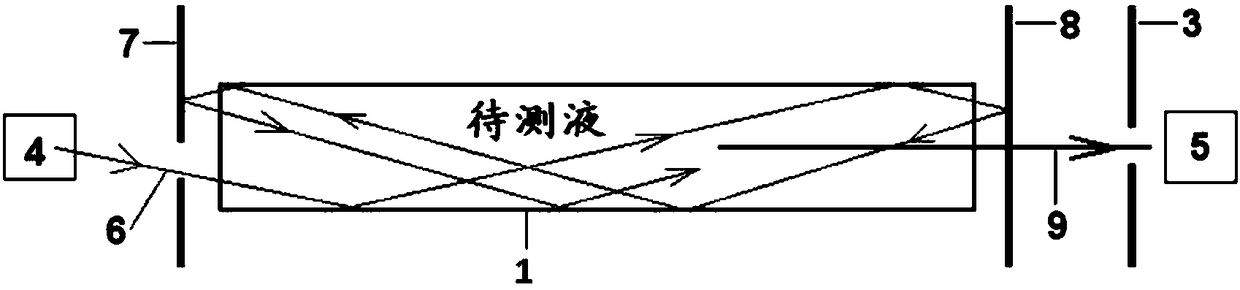

[0047] Such as figure 2 As shown, the inner diameter of the silver capillary polished on the inner wall is 0.4 mm, which serves as the light guide capillary 1.

[0048] When the light beam 6 emitted by the light source 4 passes through a small hole with an aperture of 0.3 mm on the aluminum first reflecting device 7, it enters the light guide capillary 1. Due to the high reflectivity of the inner wall of the silver-guided light-guiding capillary 1, the detection light can be restricted.

[0049] Since two reflective devices are placed at both ends of the capillary, including the first aluminum reflective device 7 with holes and the second reflective device 8 of non-porous dielectric f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap