Fault detection method for penicillin fermentation process

A penicillin fermentation and fault detection technology, applied in chemical process analysis/design, special data processing applications, instruments, etc., can solve the problems of inaccurate statistical control limits and low fault detection effect, and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The following is a specific description of the penicillin fermentation process failure detection method of the present invention through exemplary implementations.

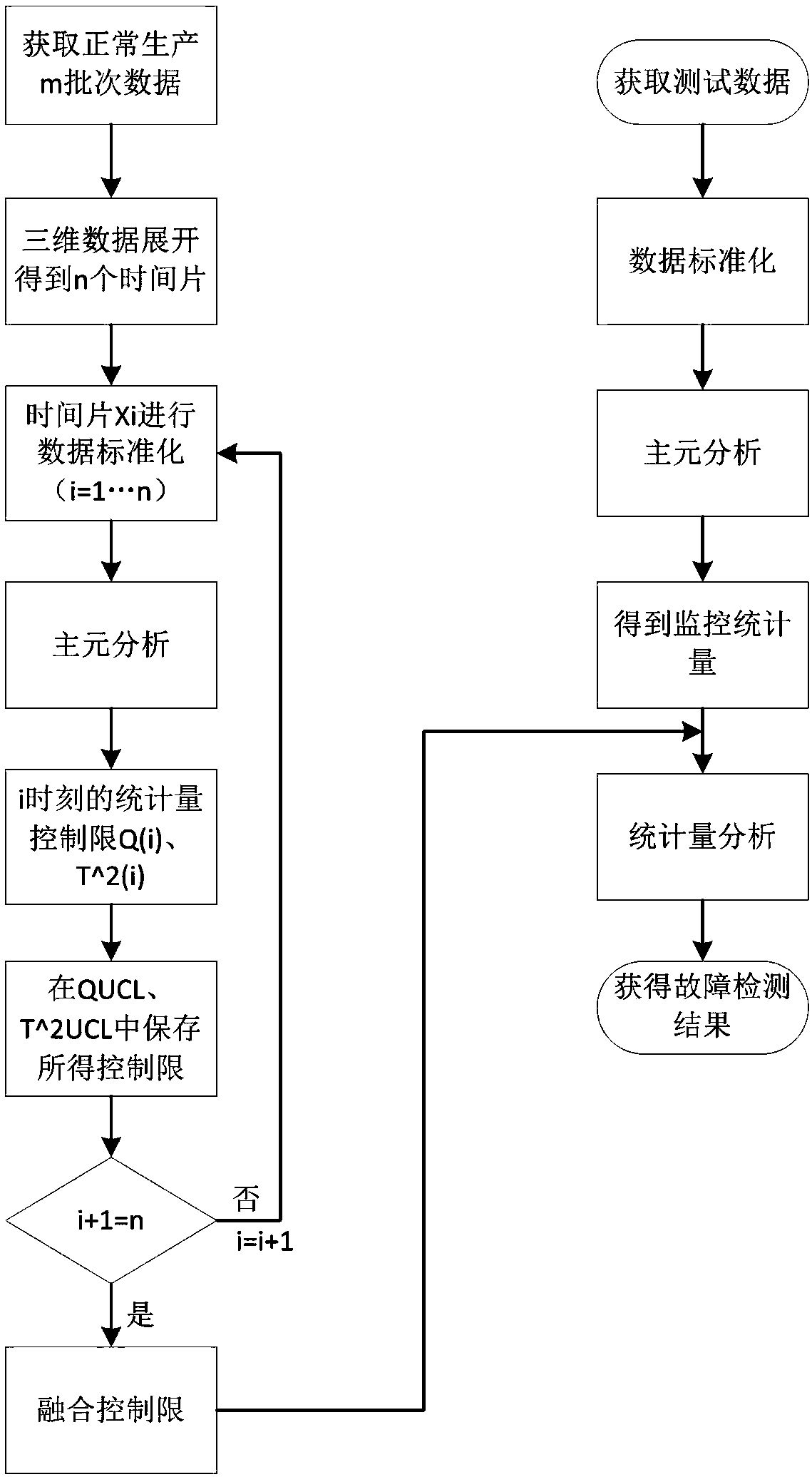

[0063] The invention provides a method for fault detection in a penicillin fermentation process, the specific steps are as follows:

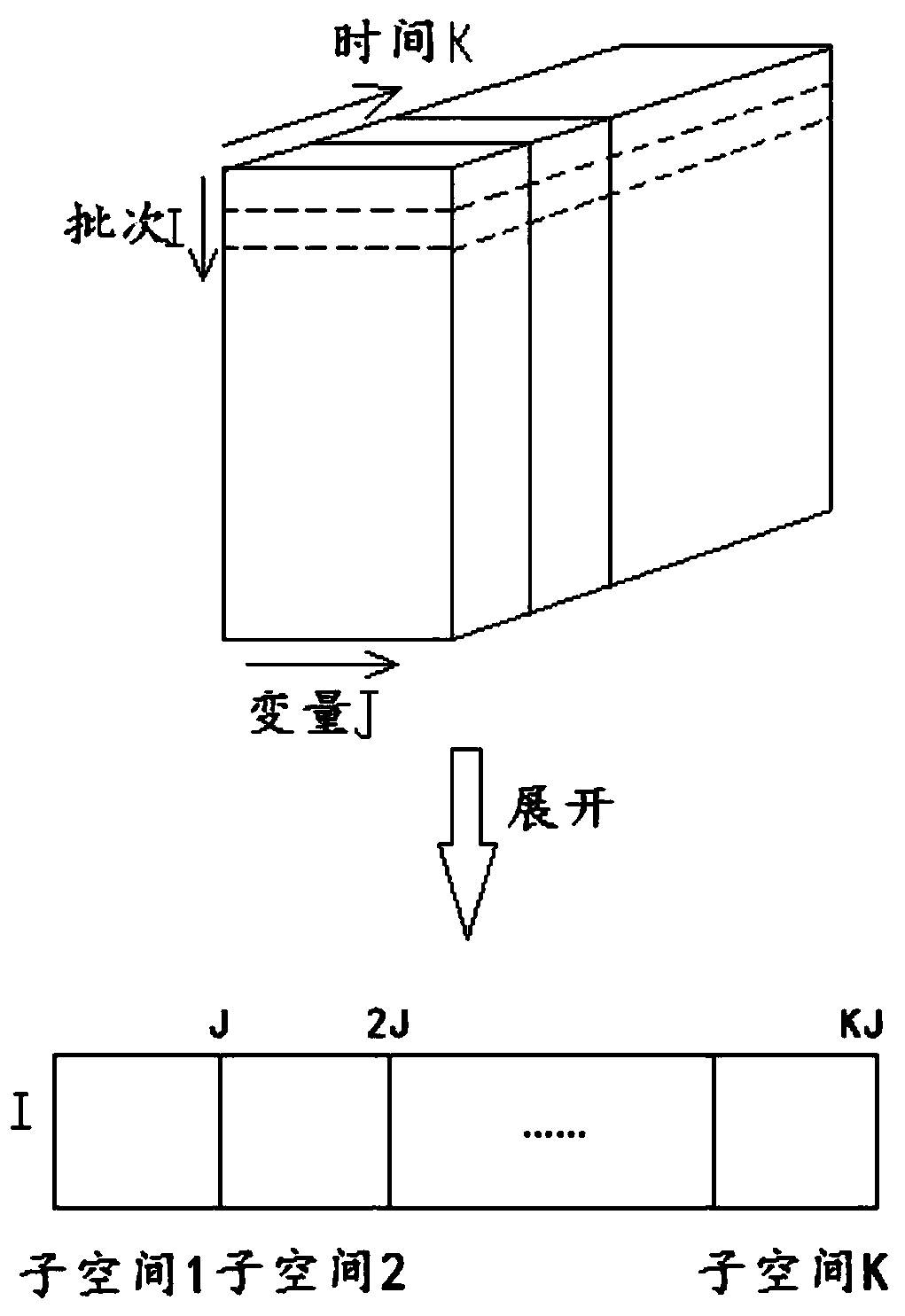

[0064] Step 1: Collect multiple batches of normal production process data. The complete data set X(I×J×K) of I batch of normal production is a three-dimensional data structure, where I represents the number of batches, J represents the number of process variables, and K Represents the number of samples. Such as figure 2 As shown, the three-dimensional data set is expanded to the right along the time axis to form a series of two-dimensional data sets (I×JK), and K time slices are obtained, that is, K two-dimensional data subspace models Xi (i=1,2 , L, K). In the two-dimensional data subspace model, each row element contains the process data of all process variables of a ba...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap