Thermally conductive molded resin article

A technology of thermal conductivity and resin molding, which is applied in the direction of semiconductor devices, heat exchange materials, semiconductor/solid device components, etc., can solve the problem of not fully satisfying heat dissipation characteristics, insufficient thermal conductivity, type or volume filling rate limitations, etc. Problems, to achieve low thermal resistance, reduce interface thermal resistance, reduce the effect of internal thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

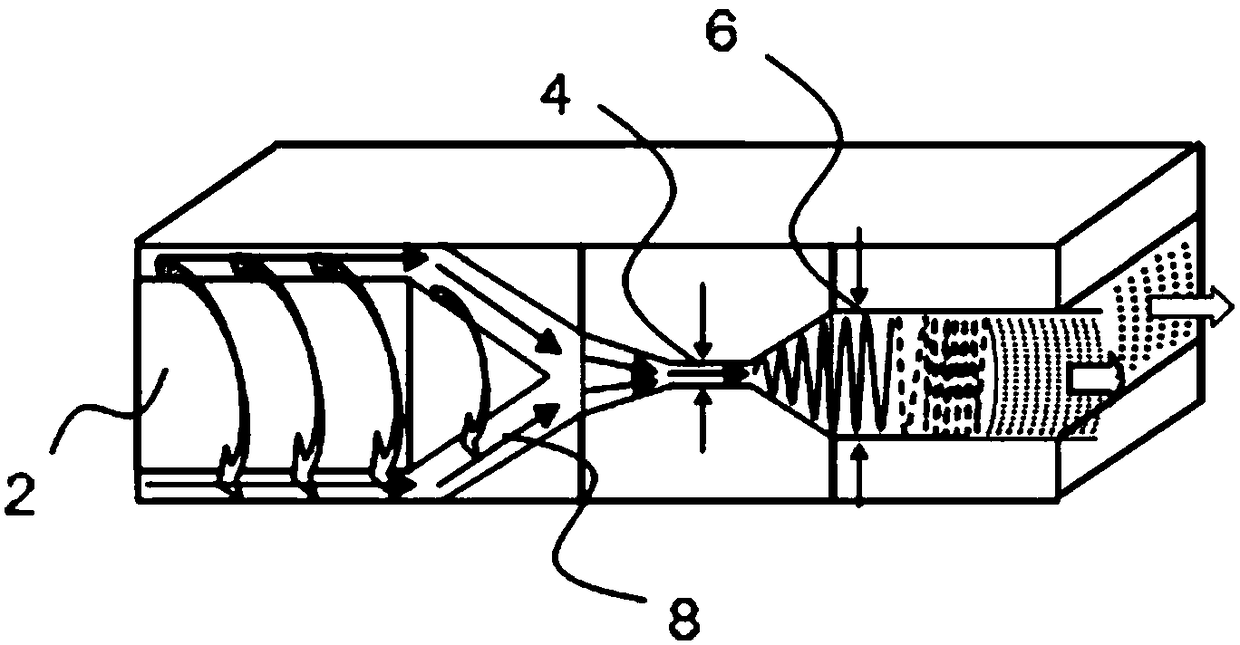

Image

Examples

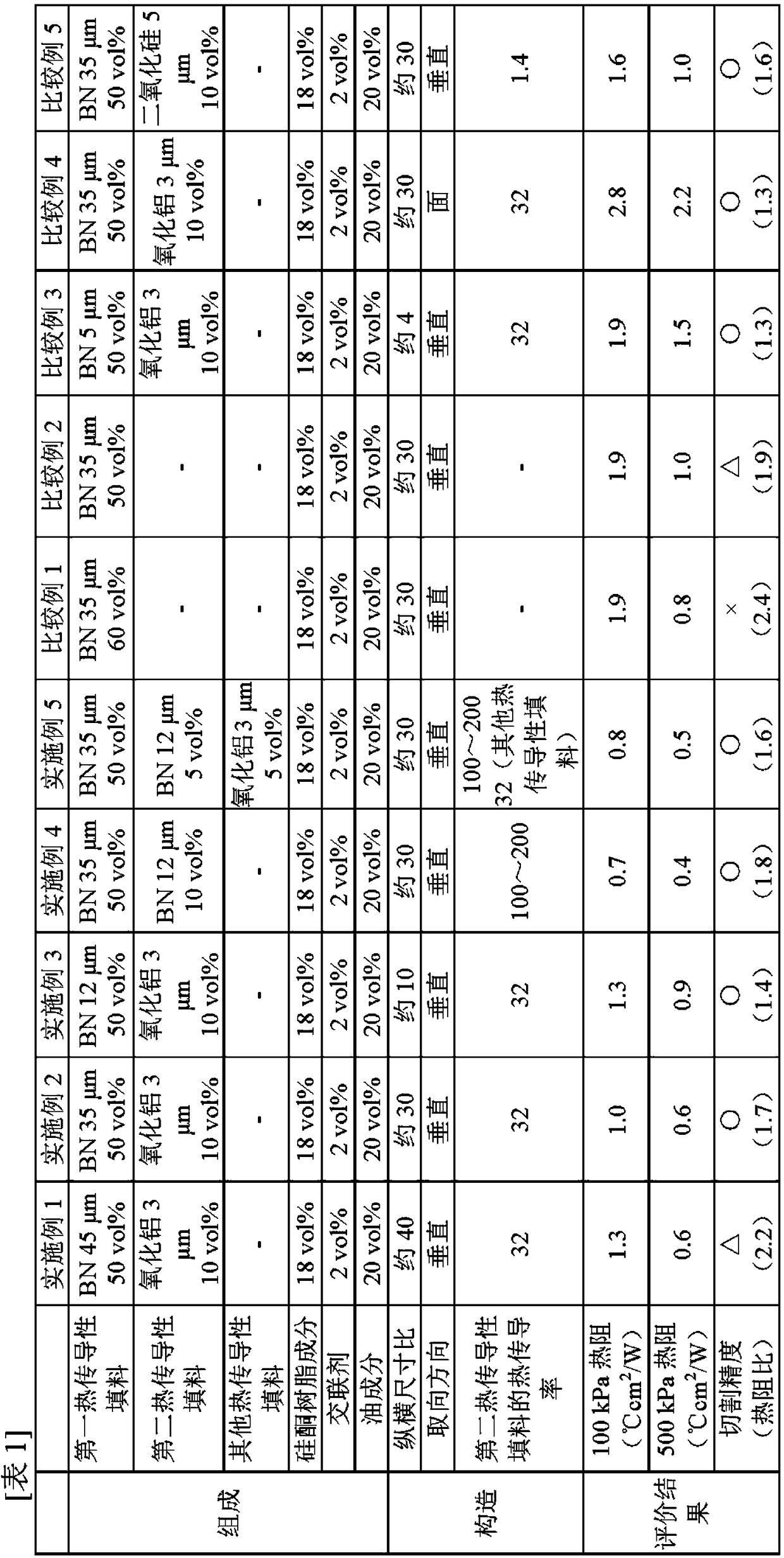

Embodiment 1

[0049] According to the preparation described in Table 1, a crosslinking agent and a thermally conductive filler were kneaded into the silicone resin component by twin rolls to obtain a strip-shaped sheet (composition as a precursor). "Silicone rubber DY32 1005U" manufactured by Toray Dow Corning Co., Ltd., flame retardant and plasticizer components were used as the silicone resin component, and "PT110" (plate-shaped boron nitride, average particle diameter of 45 μm) and “DAW-03” (aluminum oxide, average particle diameter of 3 μm) manufactured by Denka Co., Ltd. Furthermore, "RC-4" and "MR-53" manufactured by Toray Dow Corning Co., Ltd. were used as the crosslinking agent, and "ME-41F" manufactured by Momenntive was used as the flame retardant component containing metal compounds such as iron oxide. and "XC87-905". The plasticizer component is preferably a silicone oil having the same skeleton as the silicone rubber, requiring a viscosity of 100 cs to 10000 cs, and "KF-96-300...

Embodiment 2

[0058] As the thermally conductive filler, "XGP" (plate-like boron nitride, average particle size: 35 μm) and "DAW-03" (aluminum oxide, average particle size: 3 μm) manufactured by Denka Co., Ltd. were used. In the same manner, a thermally conductive resin sheet 2 was produced and evaluated. The results are shown in Table 1.

Embodiment 3

[0060] As the thermally conductive filler, "SGPS" (block boron nitride, average particle size: 12 μm) and "DAW-03" (aluminum oxide, average particle size: 3 μm) manufactured by Denka Co., Ltd. were used. In the same manner, a thermally conductive resin sheet 2 was produced and evaluated. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com