Yogurt stabilizer containing soybean polysaccharides, application of yogurt stabilizer in yogurt and preparation method of yogurt

A soybean polysaccharide and stabilizer technology, applied in the field of yogurt preparation, to achieve the effect of solving sticky taste, refreshing taste and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

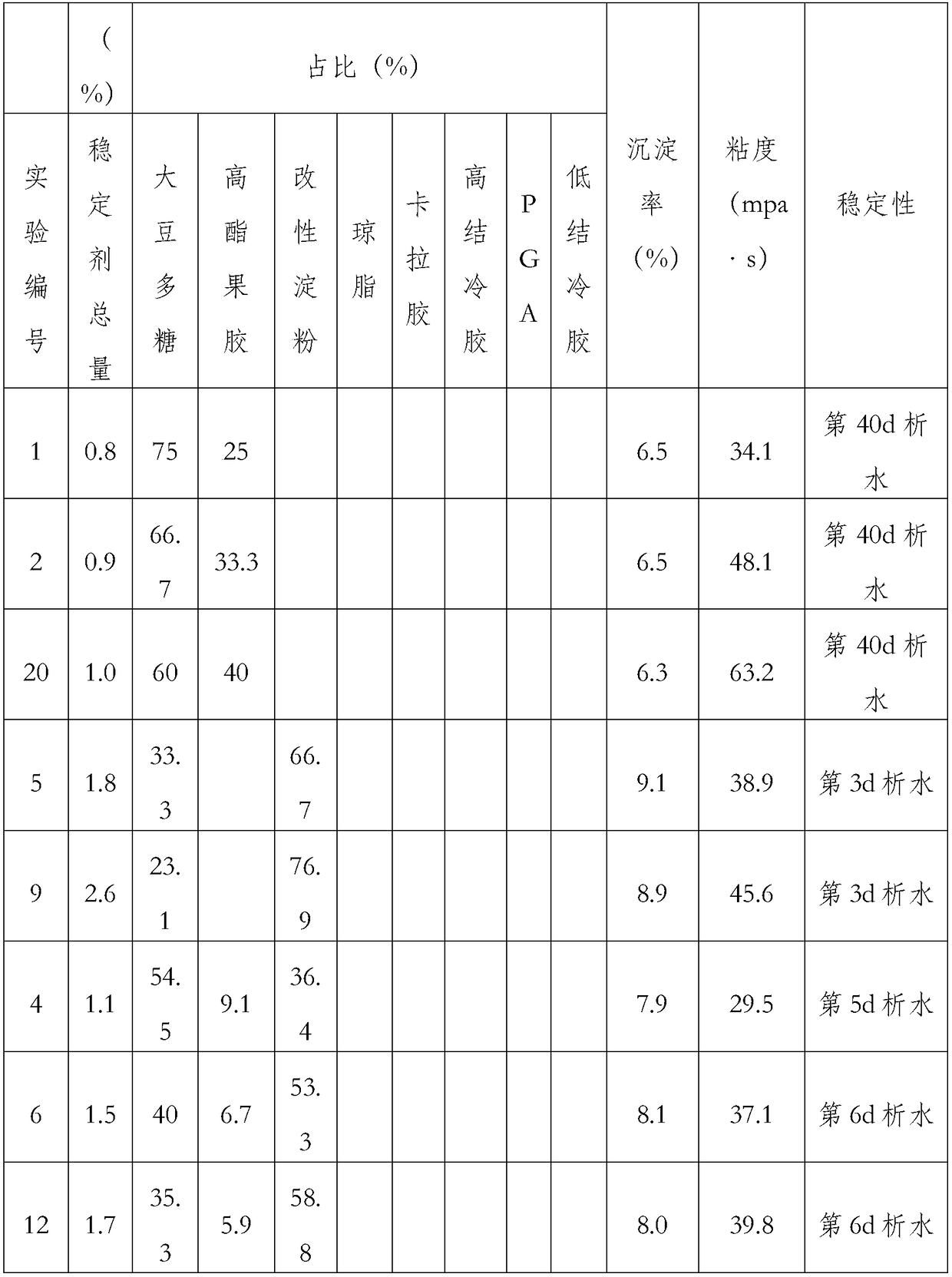

Method used

Image

Examples

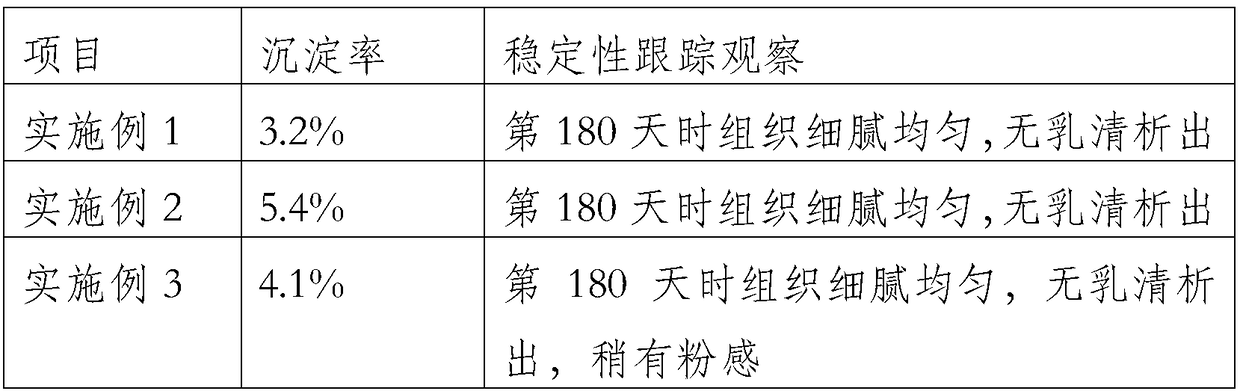

Embodiment 1

[0029] A yoghurt stabilizer is compounded and evenly mixed from the following raw materials, and calculated according to weight percentage, including: 42.9% of soybean polysaccharide, 21.4% of high-ester pectin, and 35.7% of hydroxypropyl modified starch. The non-fat drinkable normal-temperature yogurt with a protein content of 2.7% is prepared from the above-mentioned stabilizer, which is prepared from the following raw materials in percentage by weight: 1.4% of yogurt stabilizer, 8% of white sugar, 33.75% of non-fat fermented milk base, and the rest is water .

[0030] Preparation of skimmed milk base: Weigh skimmed milk powder and water, shear and redissolve with a high-speed disperser at 13,500 rpm for 5 minutes, filter, and homogenize once at 20 MPa, sterilize at 90°C for 10 minutes, cool, add bacteria, and ferment at 43°C for 6 hours , to obtain a skim milk base. Dissolve the yogurt stabilizer and white sugar in hot water to obtain a mixed solution, sterilize at 95°C fo...

Embodiment 2

[0032] A yoghurt stabilizer is compounded and evenly mixed from the following raw materials, and calculated according to weight percentage, including: 42.1% of soybean polysaccharide, 10.5% of high-ester pectin, and 47.4% of hydroxypropyl modified starch. The non-fat drinkable normal-temperature yogurt with a protein content of 2.7% is prepared from the above-mentioned stabilizer, which is prepared from the following raw materials in percentage by weight: 1.9% of yogurt stabilizer, 5% of white sugar, 33.75% of non-fat fermented milk base, and the rest is water .

[0033] Preparation of skimmed milk base: Weigh skimmed milk powder and water, shear and redissolve with a high-speed disperser at 13,500 rpm for 5 minutes, filter, and homogenize once at 20 MPa, sterilize at 90°C for 10 minutes, cool, add bacteria, and ferment at 43°C for 6 hours , to obtain a skim milk base. Dissolve the yogurt stabilizer and white sugar in hot water to obtain a mixed solution, sterilize at 95°C fo...

Embodiment 3

[0035] A yoghurt stabilizer is compounded and evenly mixed from the following raw materials, and calculated according to weight percentage, including: 28.6% of soybean polysaccharide, 14.3% of pectin, and 57.1% of hydroxypropyl modified starch. The non-fat drinkable normal-temperature yogurt with a protein content of 2.7% is prepared from the above-mentioned stabilizer, which is prepared from the following raw materials in percentage by weight: yogurt stabilizer 2.1%, white sugar 12%, skim fermented milk base 33.75%, and the rest is water . Subsequent preparation steps are the same as in Example 1.

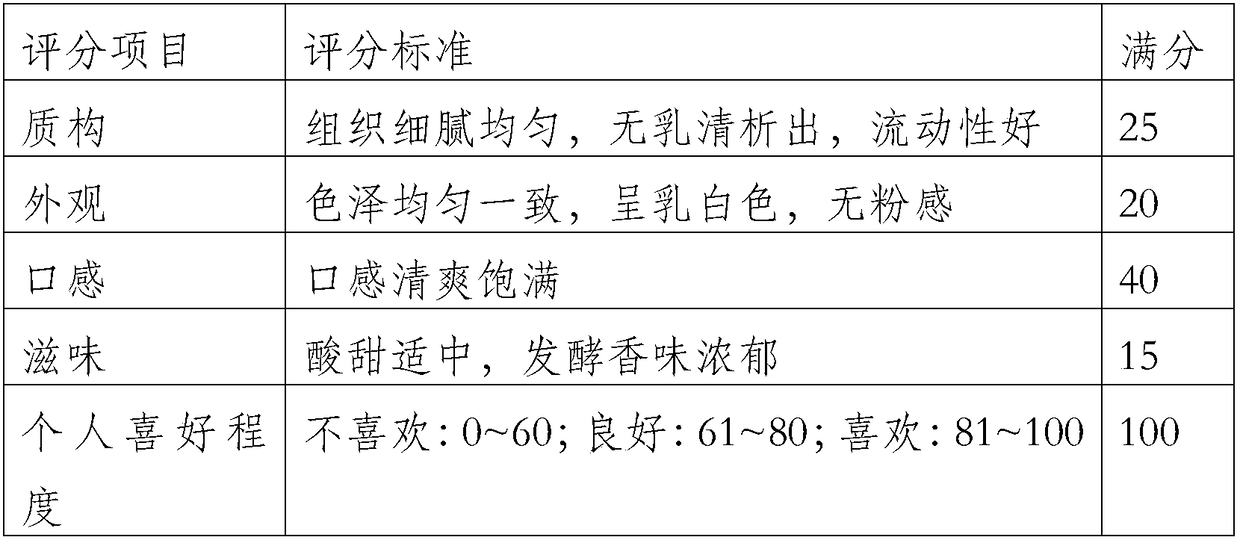

[0036] Sensory evaluation experiment: The experimental sensory evaluation team is composed of personnel who have received professional sensory training. There are 5 people in total. They will score the texture, taste, appearance and other related indicators of the samples. The scoring criteria are as follows:

[0037]Table 1 Scoring criteria for drinking yogurt

[0038]

[00...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap