Silicon micro-cup type resonant gyro processing method based on polysilicon growth method

A polysilicon growth, resonant gyroscope technology, which is applied in the process, microstructure technology, microstructure device and other directions for producing decorative surface effects, can solve problems such as low surface smoothness and small aspect ratio of silicon microcup-shaped resonant gyroscopes , to achieve the effect of high surface smoothness, wide application range and large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] A silicon microcup resonant gyroscope processing method based on the polysilicon growth method, the method is realized by the following steps:

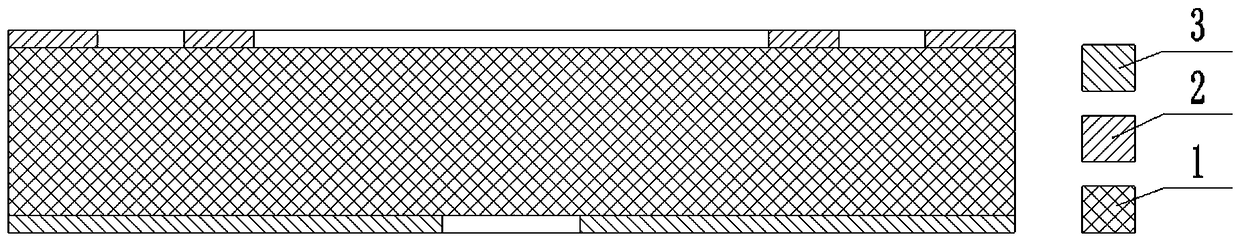

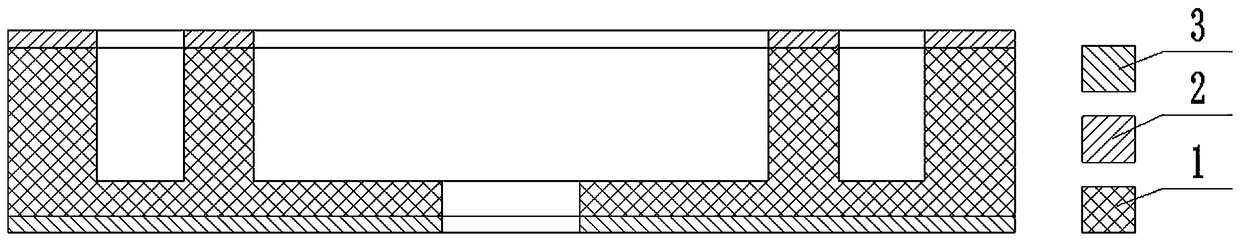

[0026] Step a: First, the first silicon nitride layer 2 is grown on the upper surface of the circular silicon substrate 1 by using an LPCVD process, and the first silicon nitride layer 2 is etched to form a first circular window and a I circular window; the axis of the first circular window and the axis of the first circular window coincide with the axis of the circular silicon substrate 1; then, the LPCVD process is used to grow on the lower surface of the circular silicon substrate 1 The second silicon nitride layer 3 is etched on the second silicon nitride layer 3 to form a second circular window penetrating up and down; the axis of the second circular window coincides with the axis of the circular silicon substrate 1, and The diameter of the II circular window is smaller than the diameter of the I circular window;

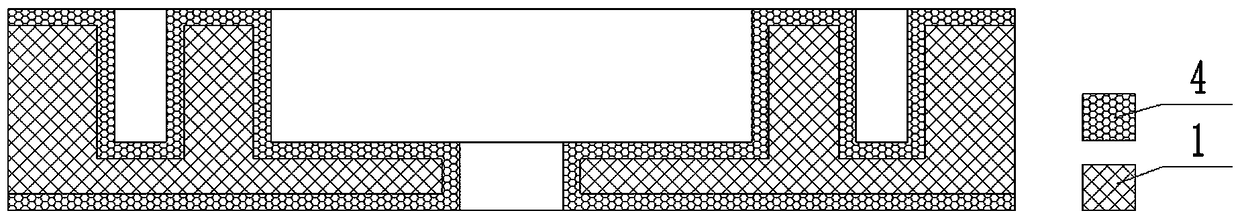

[0027] Step...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap