Device and method for preparing liquid pentaerythritol by using pentaerythritol separation mother liquor

A technology for pentaerythritol and mother liquor is applied in the field of devices for separating pentaerythritol from mother liquor to prepare liquid pentaerythritol, which can solve problems such as waste and pollute the environment, and achieve the effects of reducing production cost and increasing output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] Example 1:

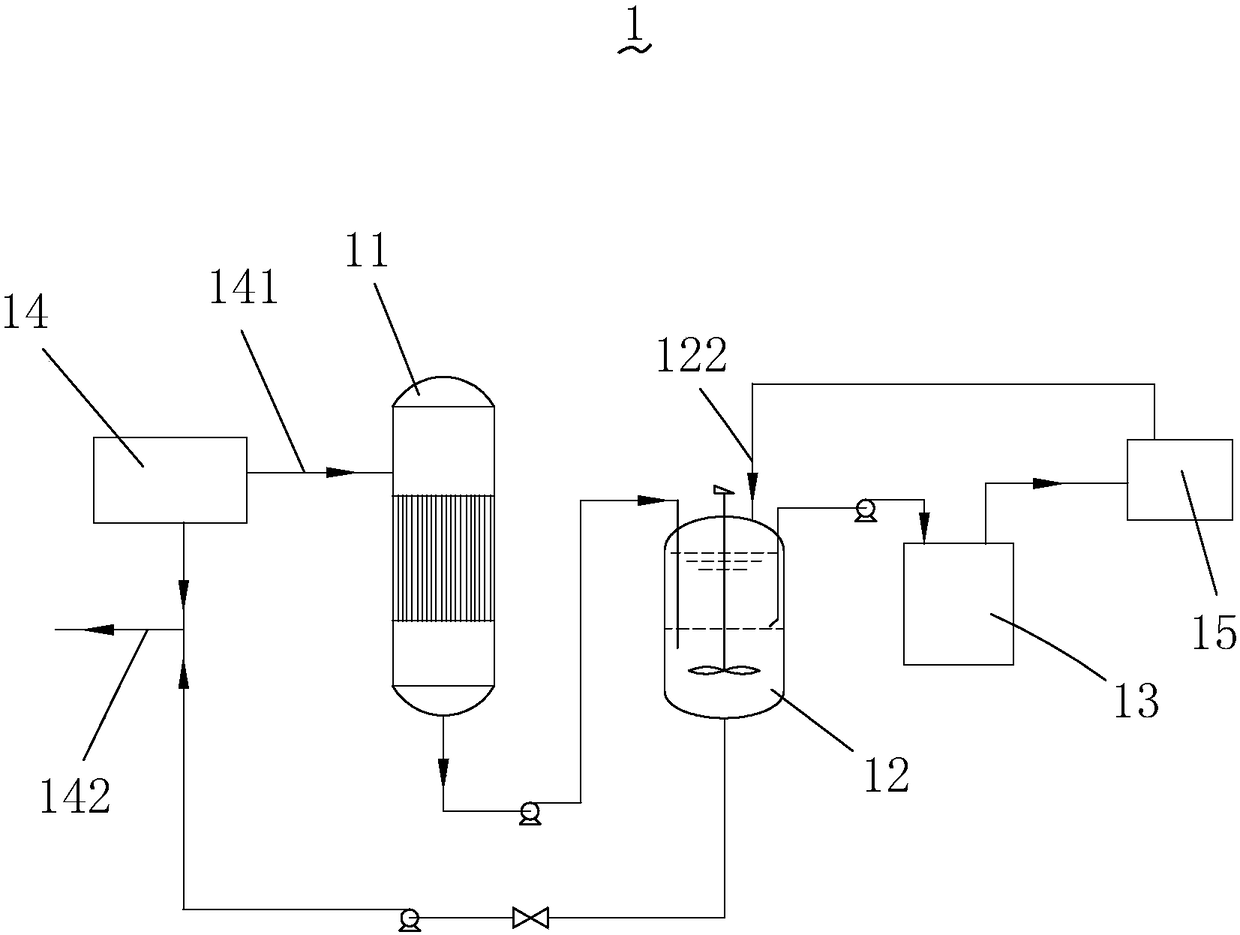

[0022] Step 1: dehydration, take 100 mL of pentaerythritol separation mother liquor, and carry out dehydration treatment with a dehydration rate of 30% through the evaporation device 11;

[0023] Step 2: extraction, adding 200 mL of extractant to the dehydrated pentaerythritol separation mother liquor in the extraction device 12, stirring and mixing for 3h, and standing for 2h to obtain the extraction phase located at the upper part of the extraction device 12 and the raffinate phase located at the lower part of the extraction device, Wherein the extraction phase is mainly a mixture of extractant, pentaerythritol, dipentaerythritol, dipentaerythritol, tripentaerythritol, lipids, etc., and the raffinate phase is mainly sodium formate or calcium formate, pentaerythritol, dipentaerythritol;

[0024] Step 3: rectifying, extracting the extraction phase into the rectifying device 13, rectifying the extractant to obtain about 20 mL of liquid pentaerythritol, and t...

Example Embodiment

[0025] Embodiment 2:

[0026] Step 1: dehydration, take 100 mL of pentaerythritol separation mother liquor, and carry out dehydration treatment with a dehydration rate of 40% through the evaporation device 11;

[0027] Step 2: extraction, adding 300 mL of extractant to the dehydrated pentaerythritol separation mother liquor in the extraction device 12, stirring and mixing for 3 h, and leaving it for 2 h to obtain the extraction phase located at the upper part of the extraction device 12 and the raffinate phase located at the lower part of the extraction device, Wherein the extraction phase is mainly a mixture of extractant, pentaerythritol, dipentaerythritol, dipentaerythritol, tripentaerythritol, lipids, etc., and the raffinate phase is mainly sodium formate or calcium formate, pentaerythritol, dipentaerythritol;

[0028] Step 3: rectifying, extracting the extraction phase into the rectifying device 13, rectifying the extractant to obtain about 30 mL of liquid pentaerythritol...

Example Embodiment

[0029] Embodiment three:

[0030] Step 1: dehydration, take 100 mL of pentaerythritol separation mother liquor, and carry out dehydration treatment with a dehydration rate of 50% through the evaporation device 11;

[0031] Step 2: extraction, adding 500 mL of extractant to the dehydrated pentaerythritol separation mother liquor in the extraction device 12, stirring and mixing for 3h, and standing for 2h to obtain the extraction phase located at the upper part of the extraction device 12 and the raffinate phase located at the lower part of the extraction device, Wherein the extraction phase is mainly a mixture of extractant, pentaerythritol, dipentaerythritol, dipentaerythritol, tripentaerythritol, lipids, etc., and the raffinate phase is mainly sodium formate or calcium formate, pentaerythritol, dipentaerythritol;

[0032] Step 3: rectifying, extracting the extraction phase into the rectifying device 13, rectifying the extractant to obtain about 35 mL of liquid pentaerythritol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap