Ternary metal oxide material for treating radionuclides in wastewater and its application

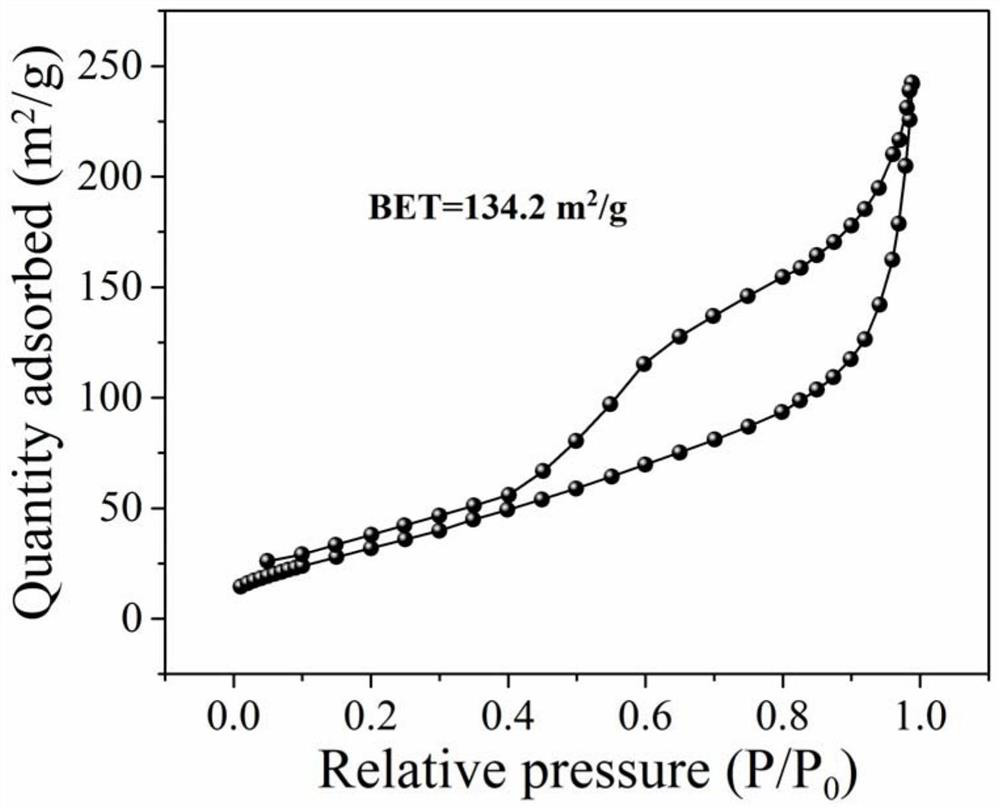

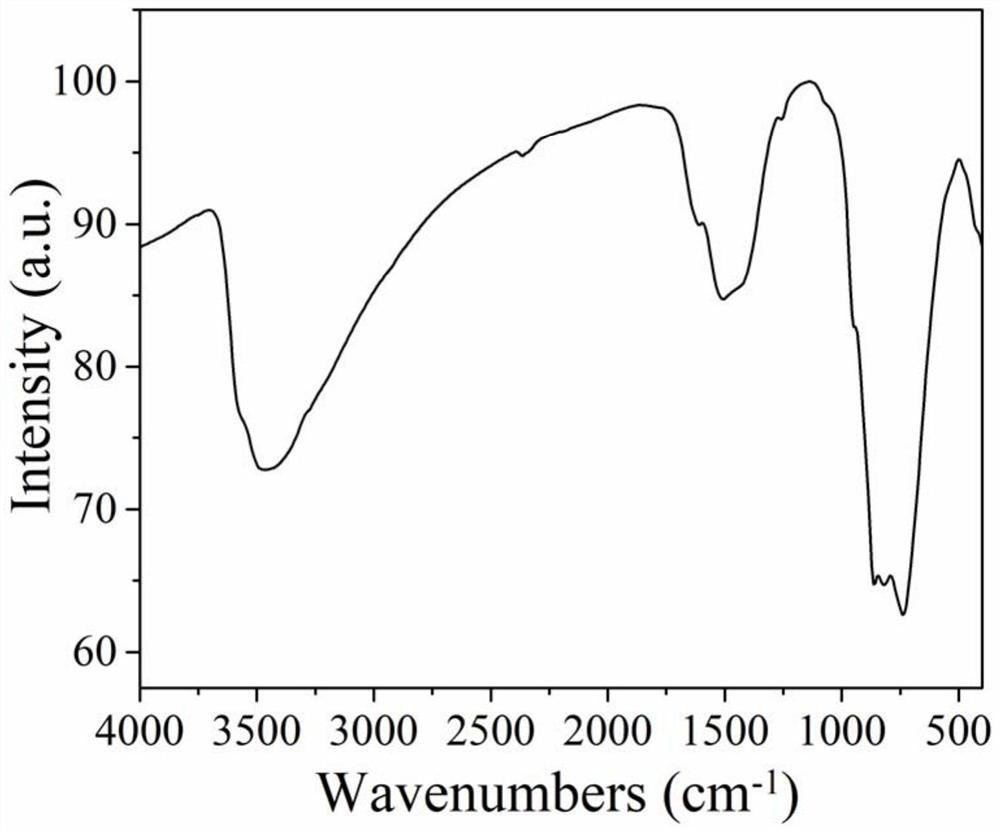

A radionuclide and ternary metal technology, applied in the field of radioactive material processing, to achieve the effects of low production cost, abundant surface active sites, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

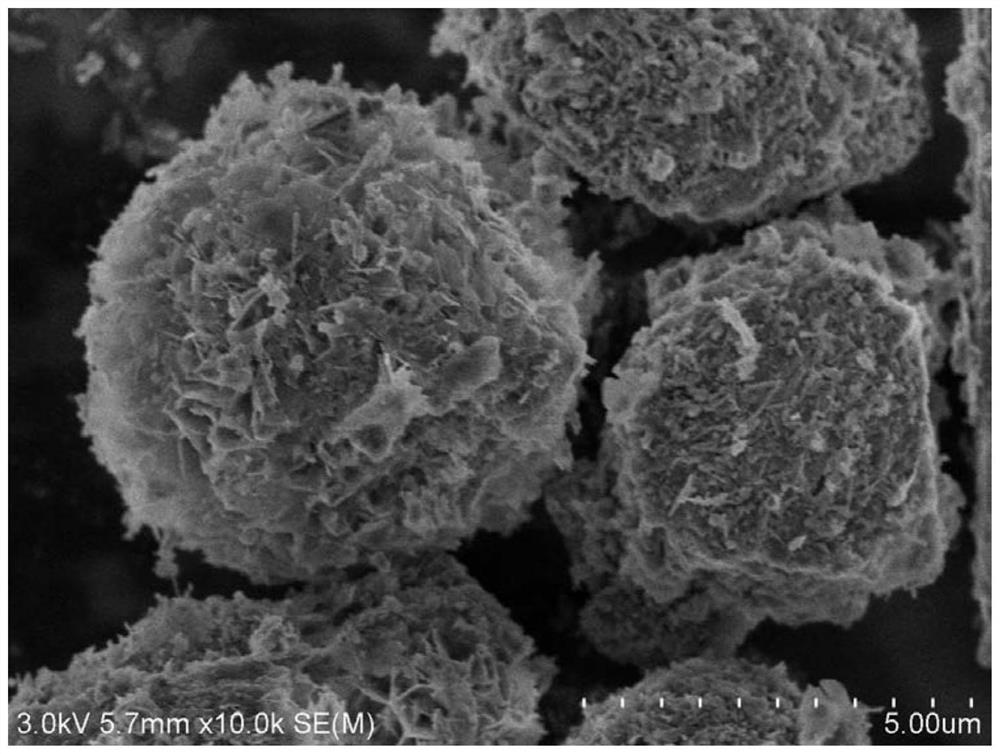

[0029] Example 1: Preparation of Co-Mo-Ni ternary metal oxide material

[0030] (1) Dissolve 6mmol cobalt nitrate, 3mmol nickel nitrate, 1mmol ammonium molybdate, 12mmol urea and 2mmol ammonium fluoride in 40mL deionized water, then stir at room temperature for 1h to obtain a homogeneous solution;

[0031] (2) The obtained homogeneous solution was transferred to a 50mL autoclave, heated in an oven at 130°C for 5h, then cooled to room temperature, centrifuged, and washed alternately with a large amount of deionized water and absolute ethanol;

[0032] (3) The obtained sample was placed in a freeze-drying oven at -40° C. for 12 hours to obtain a Co-Mo-Ni ternary metal oxide material.

Embodiment 2

[0033] Example 2: Take the Co-Mo-Ni ternary metal oxide material prepared in Example 1 and adsorb it at 25°C 238 U solution

[0034] (1) Take 50mg / L Co-Mo-Ni ternary metal oxide material, add 40mg / L, pH=5 uranyl nitrate solution, and place it in a constant temperature oscillator at 25°C;

[0035] (2) Sampling and measuring the supernatant at 0.5 / 1 / 2 / 3 / 4 / 5 / 6 / 8 / 10 / 12h respectively 238U concentration;

[0036] (3) According to the solution 238 Initial concentration of U C 0 and in solution after adsorption 238 The concentration Ce of U is calculated to obtain the adsorption amount;

[0037] (4) Draw the graph of adsorption time and adsorption amount, and the results are shown in Table 1.

Embodiment 3

[0038] Example 3: Take the Co-Mo-Ni ternary metal oxide material prepared in Example 1 and adsorb it at 35°C 238 U solution

[0039] (1) Take 50mg / L Co-Mo-Ni ternary metal oxide material, add 40mg / L, pH=5 uranyl nitrate solution, and place it in a constant temperature oscillator at 35°C;

[0040] (2) Sampling and measuring the supernatant at 0.5 / 1 / 2 / 3 / 4 / 5 / 6 / 8 / 10 / 12h respectively 238 U concentration;

[0041] (3) According to the solution 238 Initial concentration of U C 0 and in solution after adsorption 238 The concentration Ce of U is calculated to obtain the adsorption amount;

[0042] (4) Draw the graph of adsorption time and adsorption amount, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption temperature | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com