Burr removal apparatus

A kind of equipment and burr technology, applied in the field of mechanical manufacturing and processing, can solve the problems of unguaranteed product quality, large labor costs, impracticality, etc., and achieve the effect of simple and reliable processing method, stable processing process and convenient waste collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

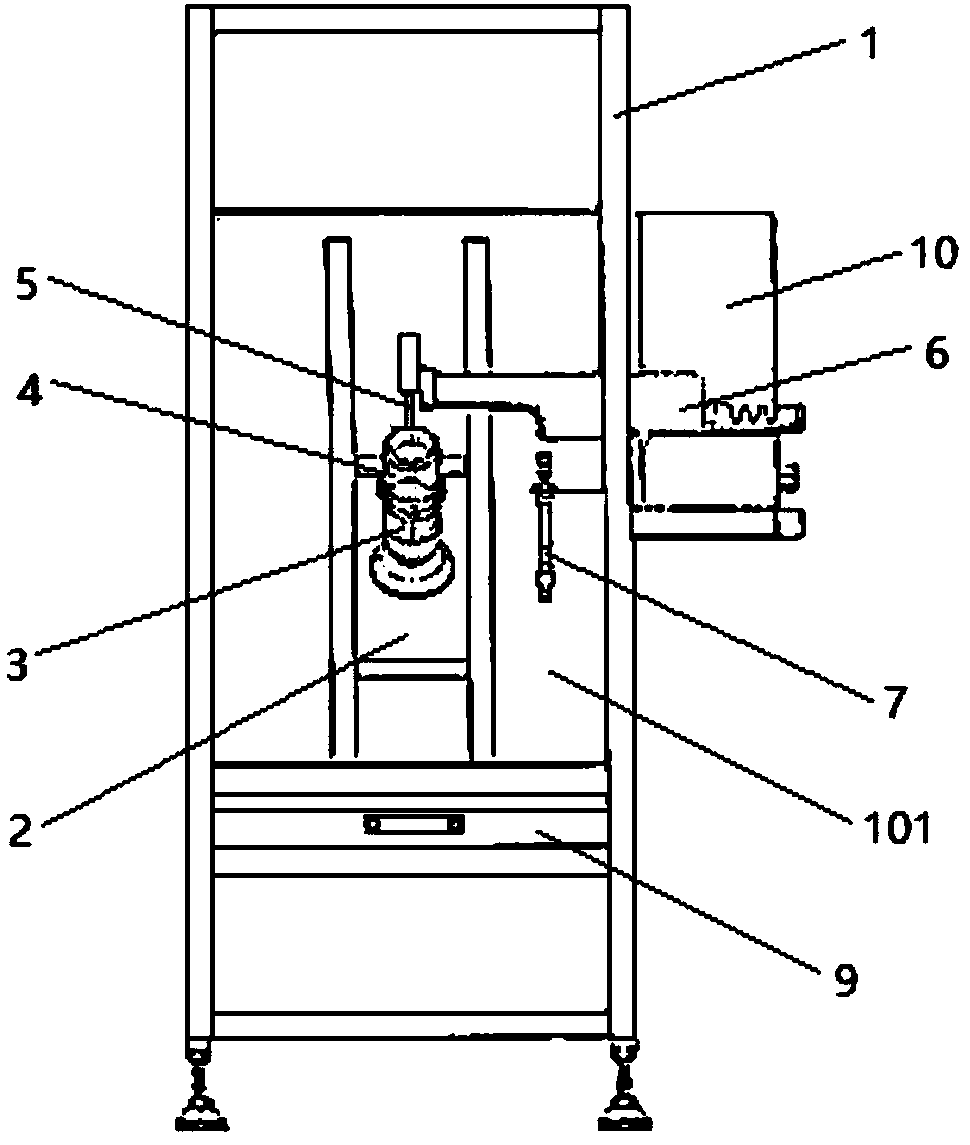

[0033] Such as figure 1 and 2 As shown, this embodiment provides a deburring equipment, the deburring equipment includes an operation box 1, a clamping device and a tool assembly; the operation box 1 is provided with an operation platform 101;

[0034] The clamping device is arranged in the operation box 1 and can move on the operation platform 101; the tool assembly includes a deburring tool 5, a mechanical arm 6 and a hydraulic cylinder 7; the deburring tool 5 and The mechanical arm 6 is connected; the hydraulic cylinder 7 is connected with the mechanical arm 6 for controlling the up and down movement of the mechanical arm 6 .

[0035] Further, the clamping device includes claws 3 and a moving module 2, and the moving module 2 includes a moving panel and a ball screw; the moving panel is arranged on the operating platform 101, and is connected with the ball screw The nut is connected; the claw 3 is fixedly connected with the mobile panel;

[0036] The ball screw drives th...

Embodiment 2

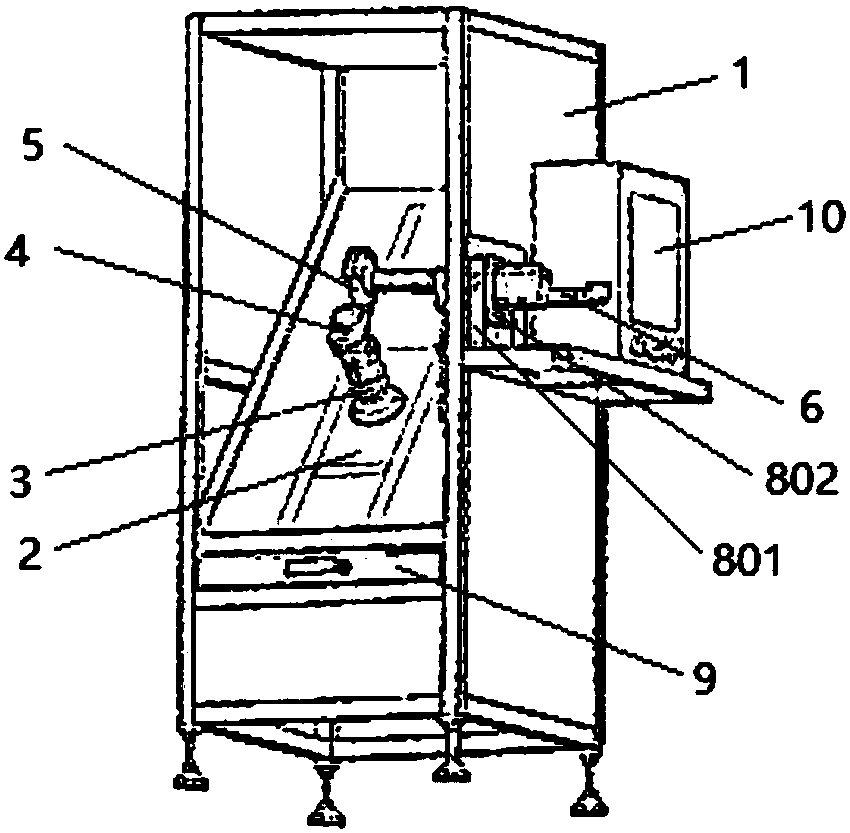

[0048] combine figure 1 and 2 As shown, this embodiment provides a deburring equipment, the deburring equipment includes an operation box 1, a clamping device and a tool assembly; the operation box 1 is provided with an operation platform 101;

[0049] The clamping device is arranged in the operation box 1 and can move on the operation platform 101; the tool assembly includes a deburring tool 5, a mechanical arm 6 and a hydraulic cylinder 7; the deburring tool 5 and The mechanical arm 6 is connected; the hydraulic cylinder 7 is connected with the mechanical arm 6 for controlling the up and down movement of the mechanical arm 6 .

[0050] Further, the clamping device includes claws 3 and a moving panel, and the claws 3 are fixedly connected to the moving panel; slide rails are provided on the moving panel, and slide grooves are provided on the operating platform 101; The moving panel can slide on the operating platform 101 , thereby driving the claw 3 to move on the operating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com