High-dispersity acidic dye and preparation method therefor

An acid dye, high dispersibility technology, applied in the direction of organic dyes, etc., can solve the problems of insufficient solubility and poor dispersibility of organic dyes, and achieve the effect of good dispersion effect, low cost, and difficult precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

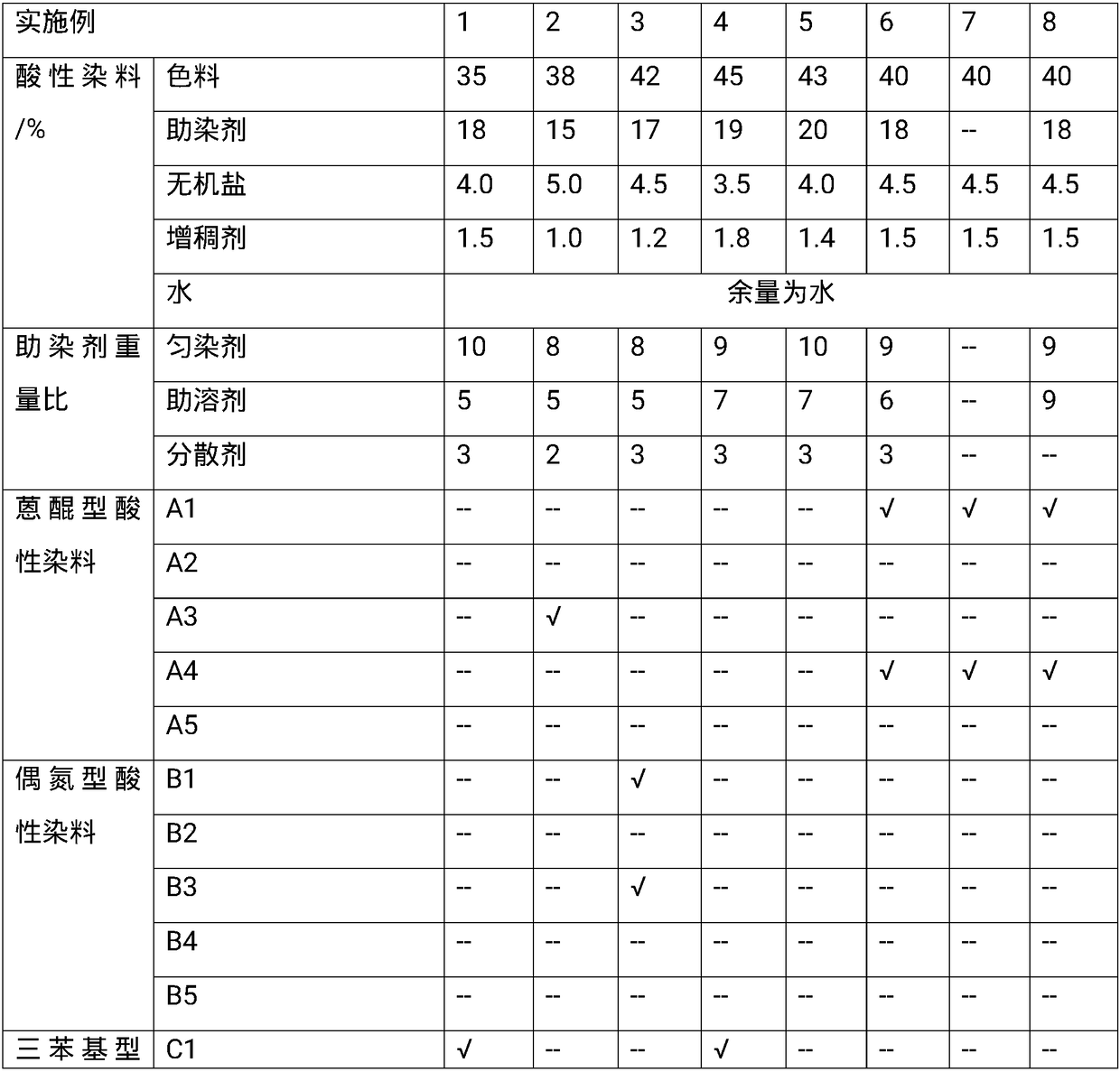

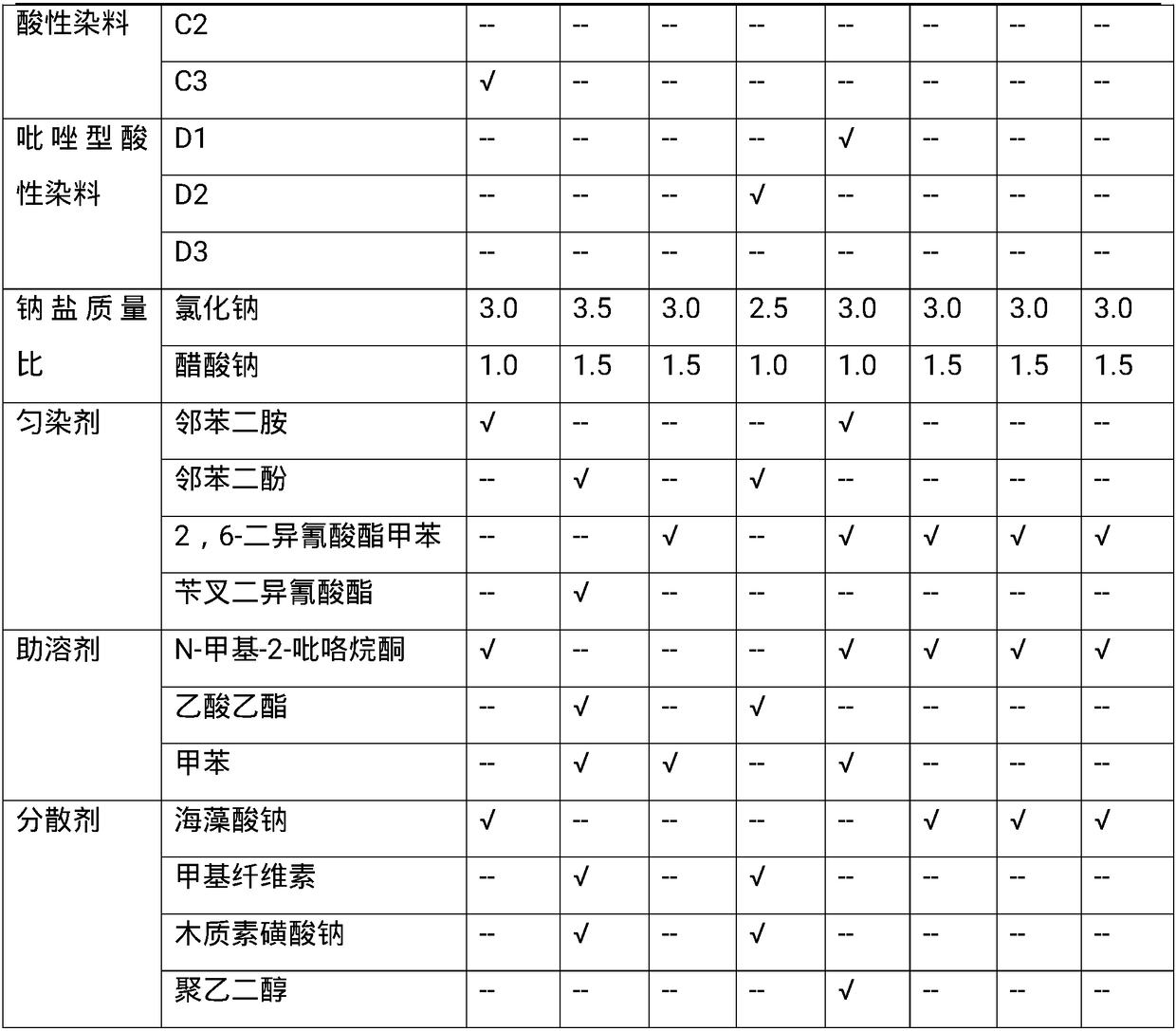

Examples

preparation example Construction

[0056] The preparation method of above-mentioned embodiment 1 highly dispersible acid dyes, comprises the steps:

[0057] S1 preparation of dyeing aids: mixing the leveling agent, co-solvent and dispersant evenly under stirring, to obtain the dyeing aids for use, weighing each raw material according to the weight part, and set aside;

[0058] S2 dye grinding: put the color material into a pulverizer and pulverize to obtain dye powder with particle size ≥ 200 mesh;

[0059] S3 preparation of acid dyes: add colorants, inorganic salts and water by weight percentage, keep warm and mix for 50 minutes after heating up, then add thickener and stir for 10 minutes, add dyeing aids in step S1 after cooling down and mix evenly, adjust pH, and prepare The resulting acid dye is packed into a dark airtight container.

[0060] Specifically, the mixing temperature in the S1 step is 10° C.; the temperature after the S3 is heated up is 100° C.; the temperature in the S3 step after the temperat...

Embodiment 1

[0062] The acid dye prepared in Example 1 has a shelf life of 24 months without deposition or precipitation.

[0063] The preparation method of above-mentioned embodiment 2 highly dispersible acid dyes, comprises the steps:

[0064] S1 preparation of dyeing aids: mixing the leveling agent, co-solvent and dispersant evenly under stirring, to obtain the dyeing aids for use, weighing each raw material according to the weight part, and set aside;

[0065] S2 dye grinding: put the color material into a pulverizer and pulverize to obtain dye powder with particle size ≥ 200 mesh;

[0066] S3 preparation of acid dyes: add colorants, inorganic salts and water by weight percentage, keep warm and mix for 60 minutes after heating up, then add thickener and stir for 20 minutes, add dyeing aids in step S1 after cooling down and mix evenly, adjust pH, and prepare The resulting acid dye is packed into a dark airtight container.

[0067] Specifically, the mixing temperature in the step S1 is...

Embodiment 2

[0069] The acid dye prepared in Example 2 has a shelf life of 24 months without deposition or precipitation.

[0070] The preparation method of above-mentioned embodiment 3 highly dispersible acid dyes, comprises the steps:

[0071] S1 preparation of dyeing aids: mixing the leveling agent, co-solvent and dispersant evenly under stirring, to obtain the dyeing aids for use, weighing each raw material according to the weight part, and set aside;

[0072] S2 dye grinding: put the color material into a pulverizer and pulverize to obtain dye powder with particle size ≥ 200 mesh;

[0073] S3 preparation of acid dyes: add colorants, inorganic salts and water by weight percentage, keep warm and mix for 55 minutes after heating up, then add thickener and stir for 15 minutes, add dyeing aids in step S1 after cooling down and mix evenly, adjust pH, and prepare The resulting acid dye is packed into a dark airtight container.

[0074] Specifically, the mixing temperature in the S1 step is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com