Graphene and organic fluorosiloxane waterborne polyurethane composite emulsion and preparation method thereof

A water-based polyurethane and composite emulsion technology, used in polyurea/polyurethane coatings, coatings, anti-corrosion coatings, etc., can solve problems such as dispersion and lamination, and achieve the effects of salt spray resistance, penetration resistance, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

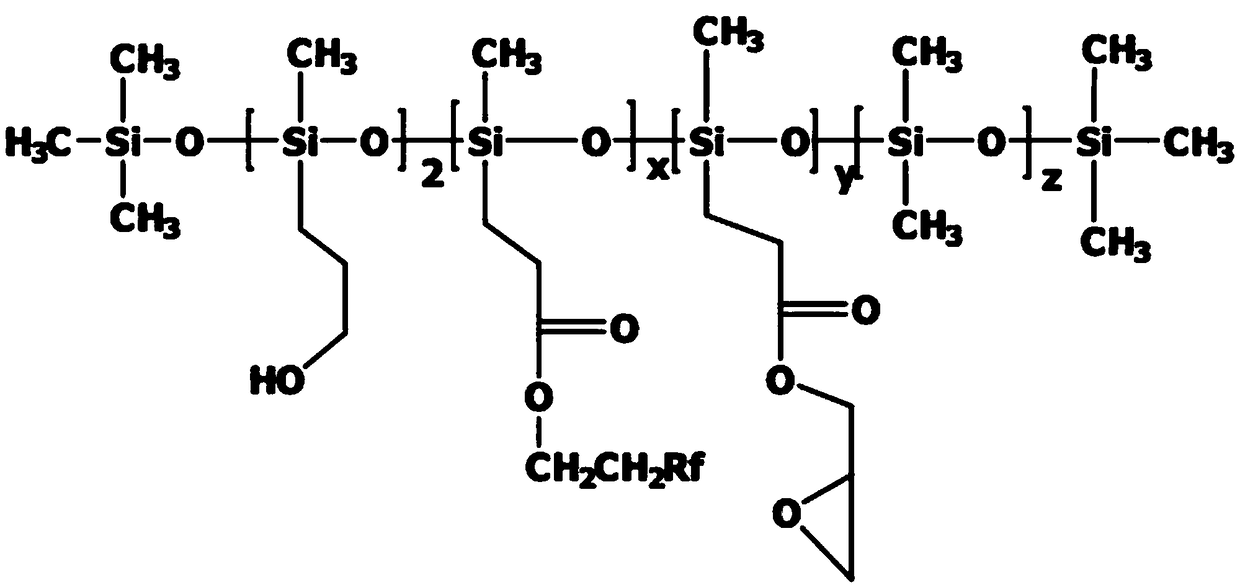

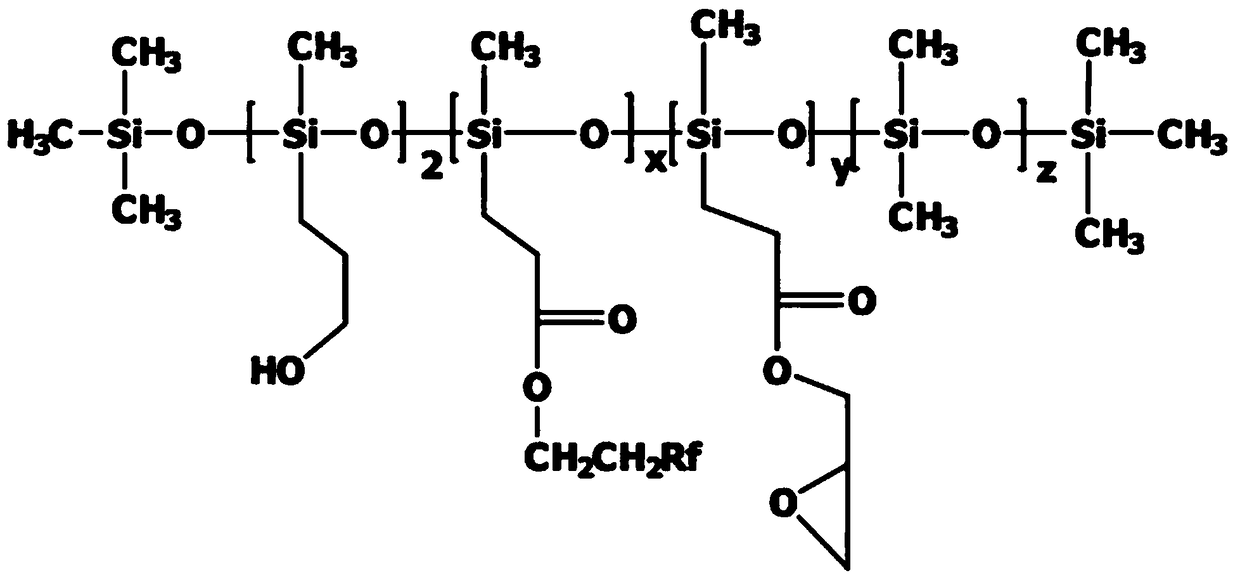

[0022] Preparation of Hydroxypolysiloxane Containing Fluorine and Epoxy

[0023] Add 100ml toluene, 50g methyl hydrogen silicone oil and 60g perfluorooctyl ethyl methacrylate (the carbon-carbon double bond molar content is 30% of the silicon-hydrogen bond content) successively in the nitrogen-protected four-necked flask, and the temperature is controlled at 100~120℃, add chloroplatinic acid / isopropanol solution dropwise under stirring, wherein the mass fraction of chloroplatinic acid is 0.01~0.02% of the sum of the mass of reactants. After the dropwise addition, react for 3~4 hours, then 75~ At 80°C, add 100g of glycidyl acrylate (the molar content of epoxy groups is 68% of the initial silicon-hydrogen bond content) and 2g of propenyl alcohol (the molar content of hydroxyl groups is 2% of the initial silicon-hydrogen bond content), and react at 90°C After 3-4 hours, the solvent and unreacted substances were removed under reduced pressure.

[0024] Preparation of Organofluoros...

Embodiment 2

[0030] Preparation of Hydroxypolysiloxane Containing Fluorine and Epoxy

[0031] Add 100ml of toluene, 50g of methyl hydrogen silicone oil and 45g of perfluorooctylethyl methacrylate (the carbon-carbon double bond molar content is 20% of the silicon-hydrogen bond content) successively in a nitrogen-protected four-necked flask, and the temperature is controlled at 100-120 degrees, add chloroplatinic acid / isopropanol solution dropwise under stirring, wherein the mass fraction of chloroplatinic acid is 0.01-0.02% of the sum of the mass of reactants. After the dropwise addition, react for 3-4 hours, then 75- At 80°C, add 120g of glycidyl acrylate (the molar content of the epoxy group is 78% of the initial silicon-hydrogen bond content) and 2g of propenyl alcohol (the molar content of the hydroxyl group is 2% of the initial silicon-hydrogen bond content), and react at 90°C After 3-4 hours, the solvent and unreacted substances were removed under reduced pressure.

[0032] Preparati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap