A kind of hot-melt adhesive film with high viscosity metal strength and preparation method thereof

A hot-melt adhesive film and metal technology, which is applied in the field of film manufacturing, can solve the problems of long-term adhesion to metal, separation of insulating materials and tinned flat copper wires, poor adhesion to metal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

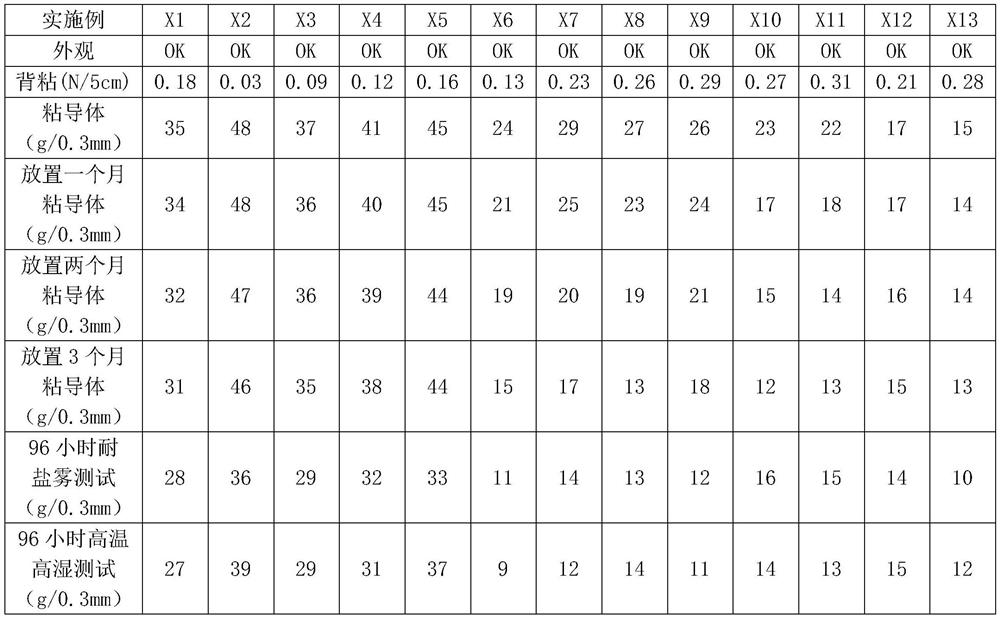

[0043] The raw material components and proportions of the adhesive layer 3 in Examples X1-X3 are shown in Table 1.

[0044]

[0045] Table 1

[0046] In Table 1, the raw materials of Example X1 and Example X2: the glass transition temperature of saturated polyester resin A is 5°C, the softening point is 90°C, the molecular weight is 50000, and the hydroxyl value is 3mgKOH / g; The glass transition temperature is 20°C, the softening point is 110°C, the molecular weight is 23,000, and the hydroxyl value is 2mgKOH / g; the glass transition temperature of bisphenol A epoxy resin is 60°C, the softening point is 125°C, the molecular weight is 23,000, and the hydroxyl value The value is 2.5mgKOH / g; the flame retardant is triphenyl phosphate and antimony trioxide; the curing agent is aliphatic isocyanate. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com