Forced torsion resistance detecting device

A detection device and anti-torsion technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of high matching degree of workpieces to be inspected and high equipment costs, so as to improve adaptability and compatibility, reduce production cost and use cost, avoid the effect of inductive components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention discloses a forced anti-rotation detection device. The specific implementation of the invention will be further described below in combination with preferred embodiments.

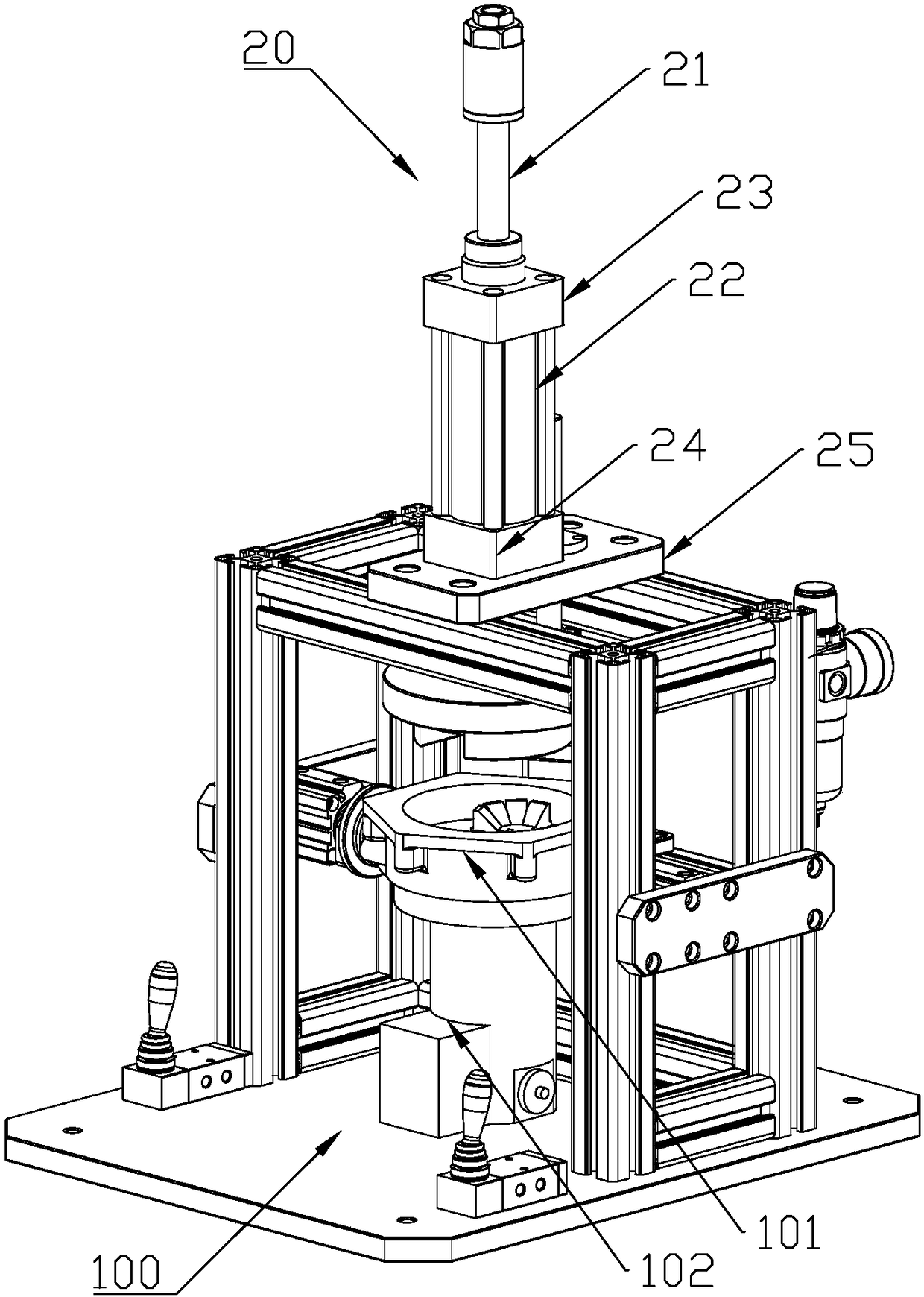

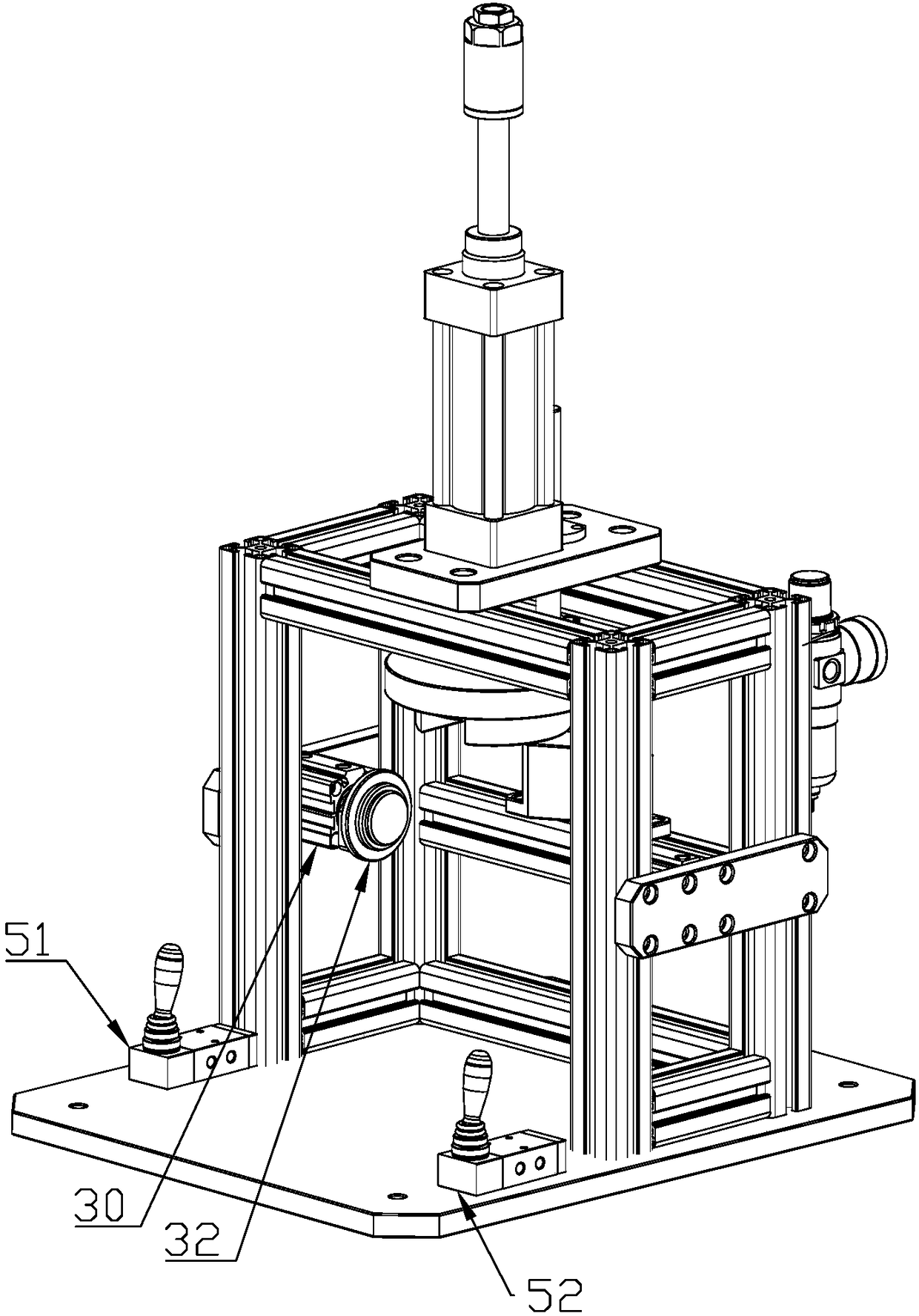

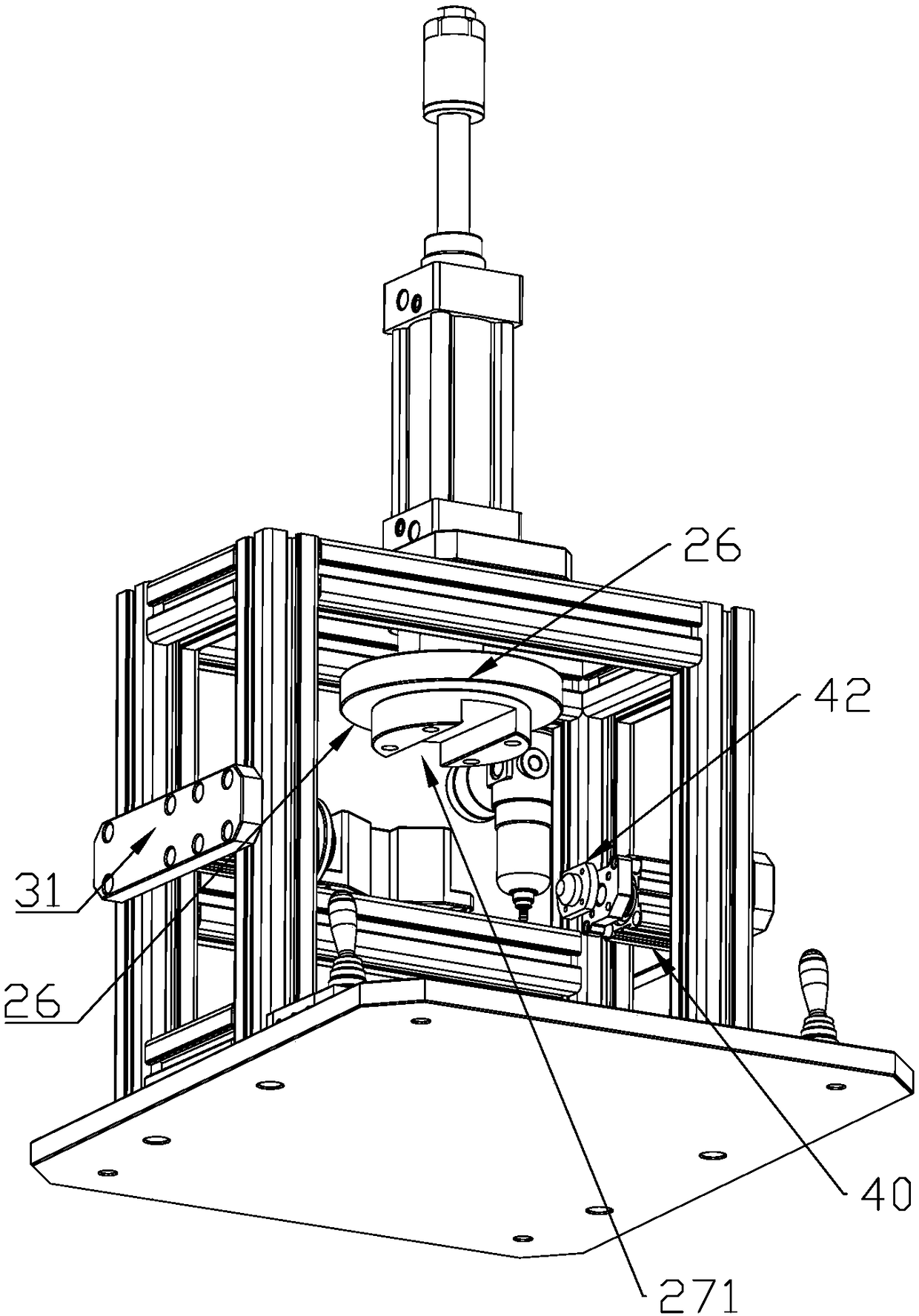

[0031] see attached Figure 1 to Figure 5 , figure 1 The combined structure of the forced anti-rotation detection device and the workpiece to be detected is shown; Figure 2 to Figure 5 The specific structure of the forced anti-rotation detection device is shown respectively.

[0032] Preferably, the forced anti-rotation detection device is used to verify the workpiece 100 to be inspected (specifically, the workpiece 100 to be inspected includes a feed port 101 and a motor seat 102, and the motor built in the motor seat 102 drives the feed port 101 to rotate ), the forced anti-rotation detection device includes:

[0033] The first cylinder 20, one end of the first cylinder 20 is internally connected to the briquetting fixture 26 and is fixedly connected with the briquetting fixture 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com