Solar drying box, drying rack and drying components

A technology of drying boxes and drying racks, which is applied in the direction of solar thermal energy, solar thermal power generation, solar collectors, etc., can solve the problems of inconvenience, energy waste, consumption, etc., achieve simple drying operation, reduce energy consumption, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

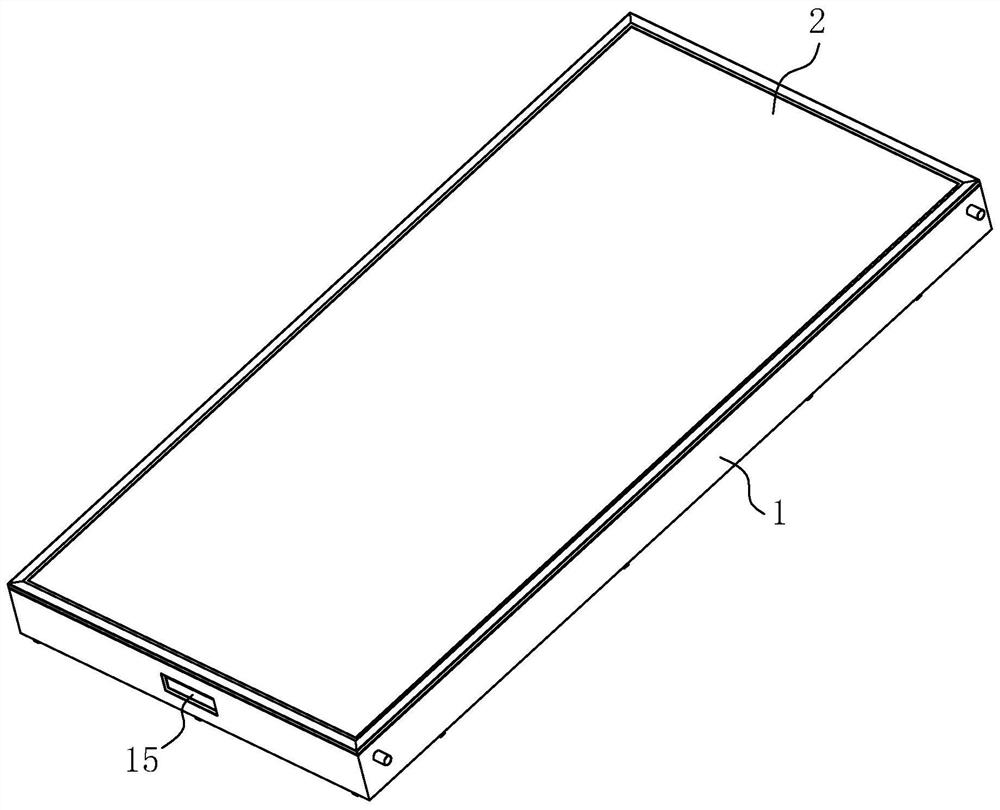

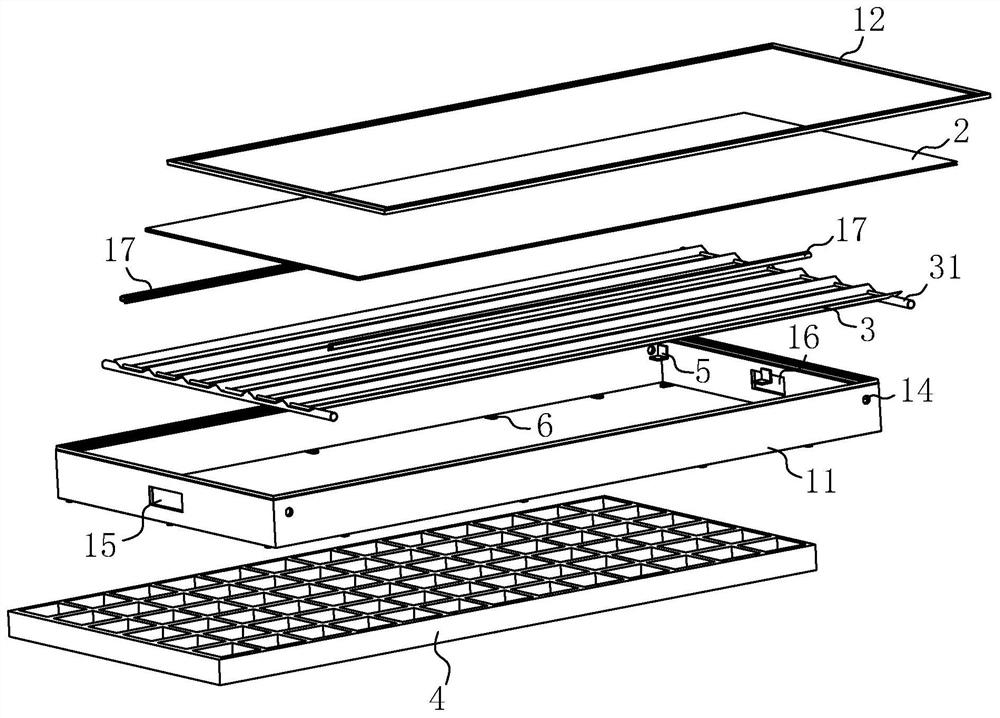

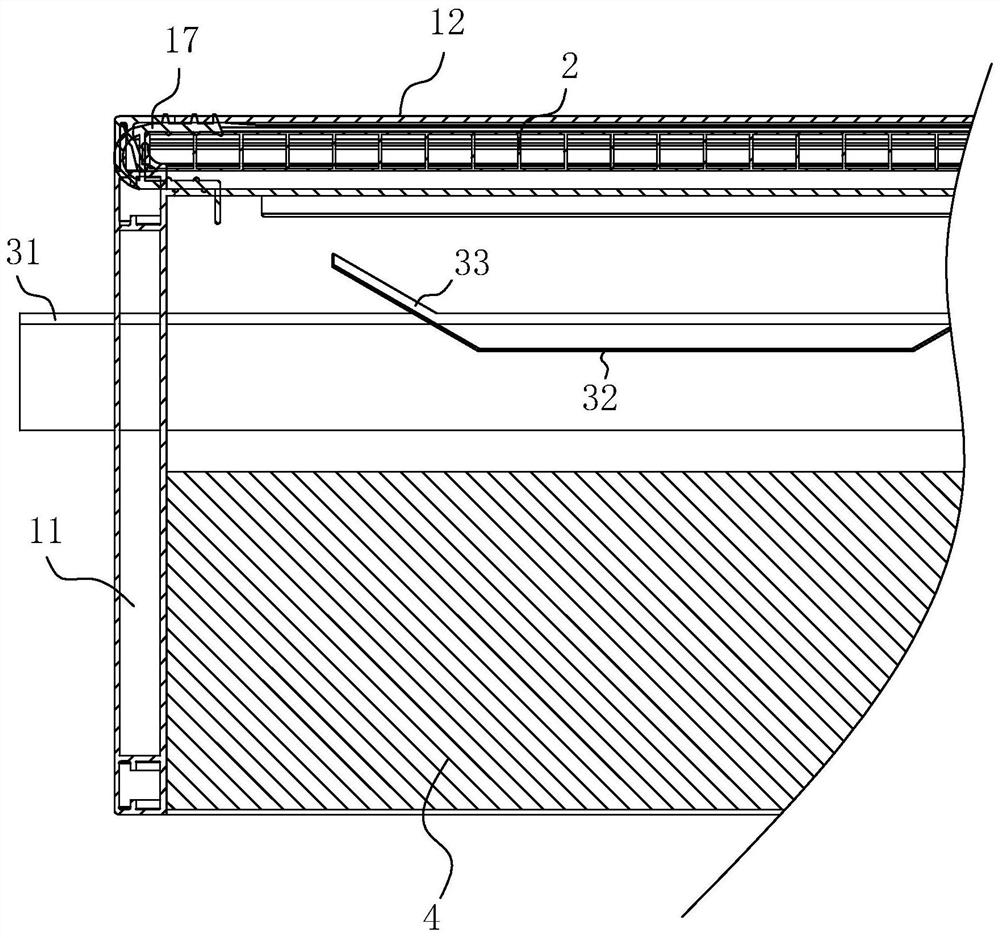

[0056] A kind of solar drying oven, such as figure 1 and figure 2 As shown, it includes: an installation frame body 1, the installation frame body 1 includes an outer frame 11, and a bead 12 engaged with the outer frame 11, and an installation groove 13 is formed between the bead bar 12 and the outer frame 11 (see Figure 4 ); inserted into the installation groove 13 and pressed against the light-transmitting heat insulation board 2 assembled with the installation frame 1 by the pressure strip 12; the solar heat collector core 3 carried on the installation frame 1, the solar heat collector core 3 is provided with a supporting rod 31, and the outer frame 11 is provided with a mounting hole 14 compatible with the supporting rod 31, and the supporting rod 31 is plugged into the mounting hole 14; and, it is detachably assembled on the mounting frame 1 The material storage box 4 used to hold the materials to be dried, the solar heat collector core 3 is located between the light-t...

Embodiment 2

[0067] A drying component such as Figure 5 and Image 6 As shown, it includes: a drying rack and a drying box as described in Embodiment 1, and the drying rack is used to place the drying box.

[0068] Wherein, the drying frame includes: a supporting frame 7, in which an accommodating opening 71 compatible with the outer frame 11 is formed; a plurality of supporting corners for supporting the drying box carried around the supporting frame 7 8. A plurality of support angle codes 8 encircle and form an accommodating space for the drying box to be placed and matched with the outer frame 11; When placed in the opening 71 , the support rod set 9 can be folded to fit the drying box and limit the drying box in the accommodating opening 71 .

[0069] Specifically, the support frame 7 is generally a rectangular frame, assembled from square steel or other standard profiles by welding or bolting.

[0070] The support angle bracket 8 includes: a first support part 81 fixed to the oute...

Embodiment 3

[0076]A drying component, the difference between this embodiment and Embodiment 2 is that, as Figure 7 and Figure 8 As shown, a first reinforcing rod 101 and a second reinforcing rod 102 are respectively hinged on both sides of the supporting frame 7, and the free ends of the first reinforcing rod 101 and the second reinforcing rod 102 are detachably connected to the second supporting rod 92 by bolts. , and when the drying box is placed in the accommodating port 71, and the first support rod 91 and the second support rod 92 are rotated to fit the drying box, the first reinforcing rod 101 and the second reinforcing rod 102 can be rotated To fit the first support rod 91 and the second support rod 92; the first reinforcing rod 101 is provided with a third connecting hole 103, and the second reinforcing rod 102 is provided with a fourth connecting hole 104, and when the first When the reinforcing rod 101 and the second reinforcing rod 102 are rotated to fit the first supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com