Novel fastener

A fastener, a new type of technology, applied in the field of mechanical parts, can solve problems such as poor meshing, difficult implementation, and embedding difficulties, and achieve the effect of preventing detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

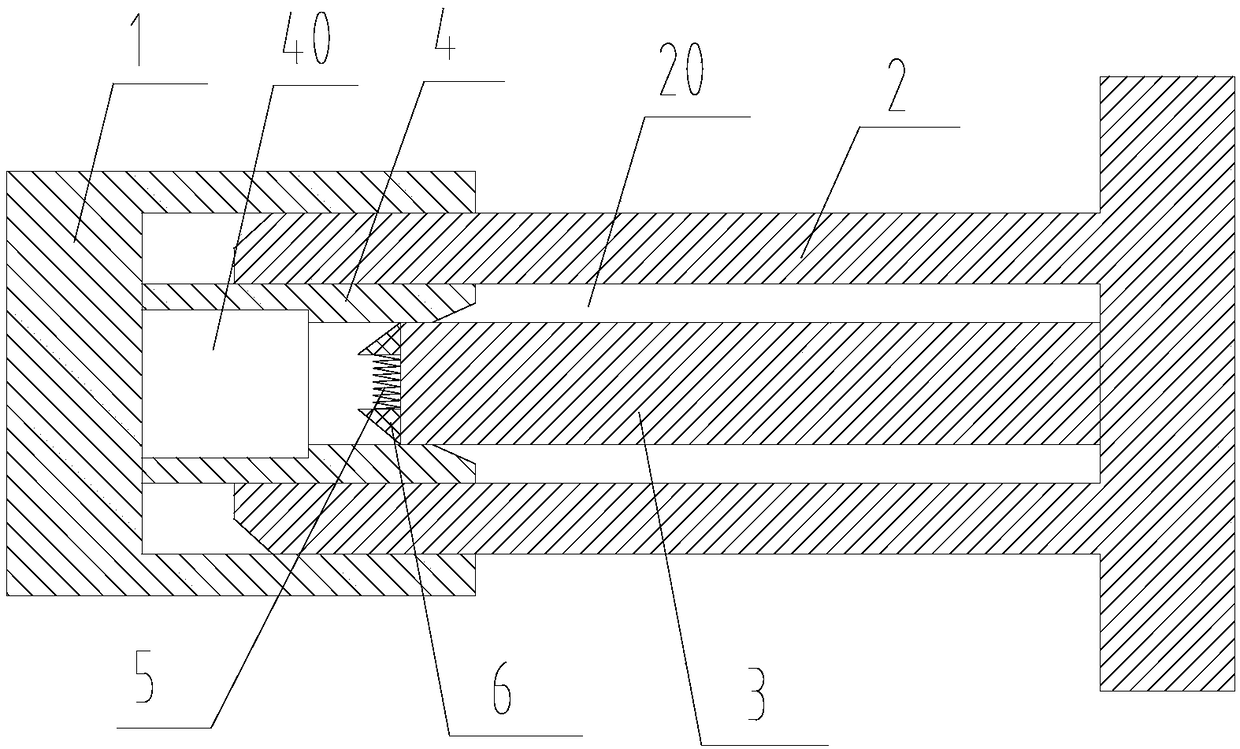

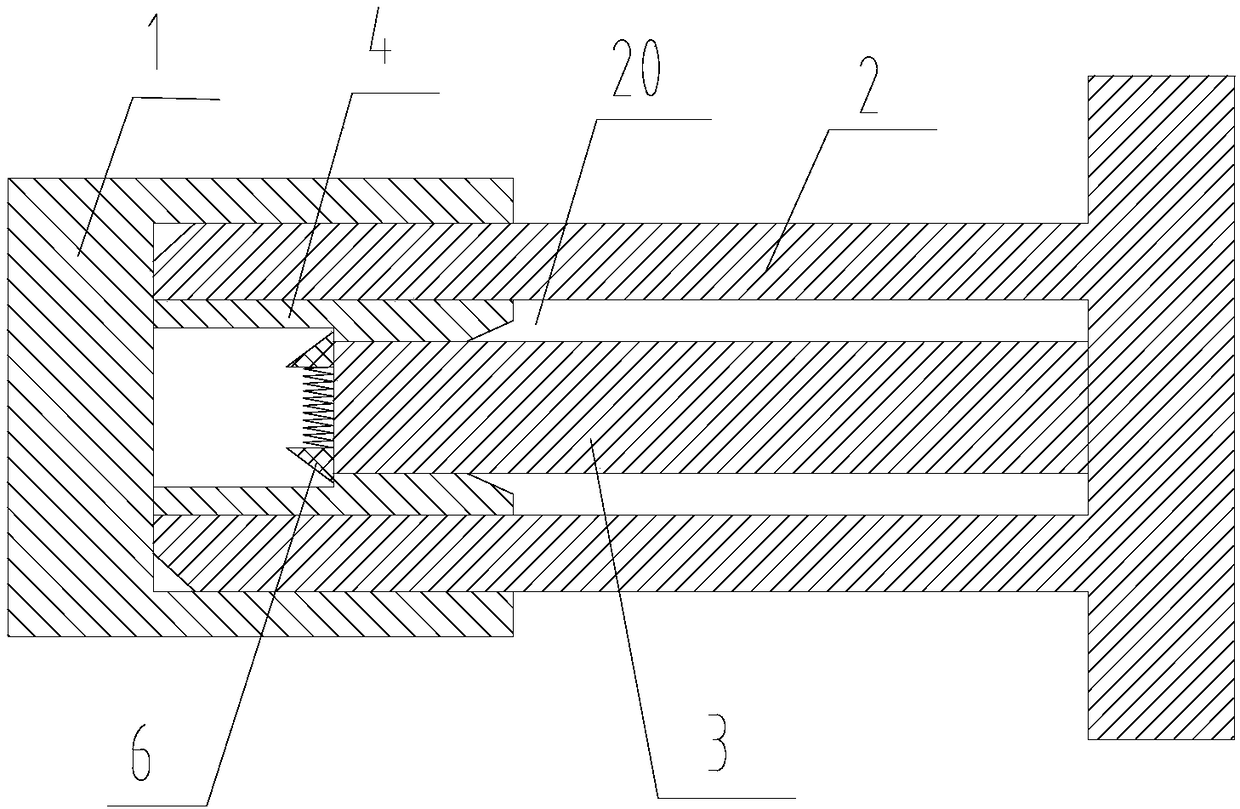

[0018] Reference figure 1 , The present invention proposes a new type of fastener, nut 1, bolt 2, first cylinder 3 and second cylinder 4.

[0019] The nut 1 is provided with internal threads and matched with the external threads on the bolt 2. The nut 1 is threadedly connected to the bolt 2 from the first end of the bolt 2, and the bolt 2 is provided with a first cavity 20 penetrating the first end surface of the bolt 2 , The first cylinder 3 is installed in the first cavity 20. The second cylinder 4 is installed inside the nut 1, and a step hole 40 is provided inside the second cylinder 4.

[0020] When the nut 1 and the bolt 2 are connected, the second cylinder 4 is inserted into the first cavity 20 and the first cylinder 3 is inserted into the step hole 40.

[0021] A spring 5 is installed on the first column 3, the middle of the spring 5 is fixed on the first column 3, and both ends of the spring 5 are movable ends, and both ends of the spring 5 are connected with a sliding bloc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap