Partition agent for ferrite body and its preparation and treatment method after use

A technology of release agent and ferrite, which is applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of kerosene volatilization, great harm to human body, manual wiping, etc., and achieve cost reduction, Good demoulding effect and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

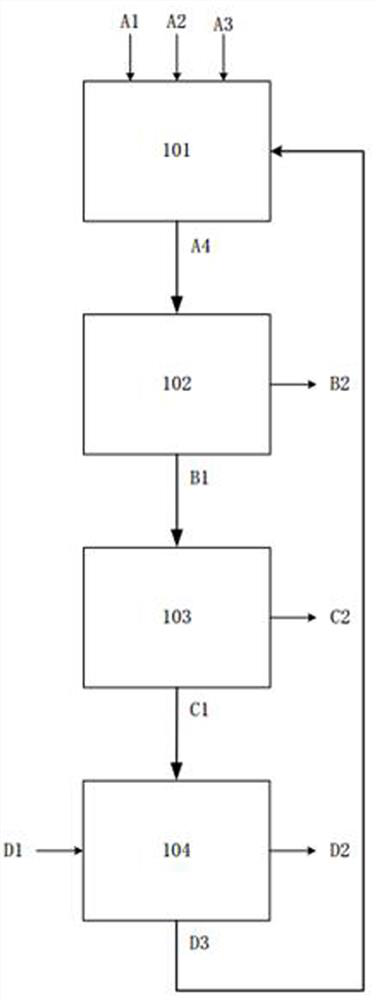

Method used

Image

Examples

Embodiment 1

[0031] A release agent for ferrite body, the release agent is composed of base oil, emulsifier, anti-rust agent, the parts by weight of each component are: 45 parts of base oil, 45 parts of emulsifier, 10 parts of anti-rust agent ; Described base oil is the mixture of 15 parts by weight of Fuchs oil and 30 parts by weight of propylene oxide condensate; Described emulsifier is 35 parts by weight of fatty alcohol polyoxyethylene ether and parts by weight A mixture of 10 parts of sorbitan fatty acid ester; the antirust agent is a mixture of 4 parts by weight of triethanolamine oleic acid soap and 6 parts by weight of oleic acid diethanolamide; the above-mentioned release agent can be diluted into release agent by distilled water For the diluent, the ratio of parts by weight of the release agent to distilled water is 1:20.

Embodiment 2

[0033] A method for preparing a release agent for a ferrite body, first mixing 35 parts by weight of fatty alcohol polyoxyethylene ether and 10 parts by weight of sorbitan fatty acid ester to make an emulsifier; 15 parts of Fox oil and 30 parts by weight of propylene oxide condensate are mixed to obtain base oil; 4 parts by weight of triethanolamine oleic acid soap and 6 parts by weight of oleic acid diethanolamide are mixed to obtain anti rust agent; slowly add the base oil prepared above in the emulsifier prepared above, and carry out the dropwise addition at a temperature of 30 ° C, a stirring speed of 500 rpm, and mixing and stirring for 30 minutes; then add the anti-rust agent prepared above agent, continue to stir for 30 minutes, that is, it is prepared as a release agent for ferrite body. Dilute the release agent with distilled water at a ratio of 1:20 to form a release agent diluent before use. The water spray speed during dilution is 400mm / s, and the water spray time ...

Embodiment 3

[0035]A treatment method for the use of the release agent for ferrite blanks. The waste liquid formed after the use of the release agent is continuously processed under the conditions of temperature 180°C, pressure 2Mpa, and rotation speed 600r / min by using a kettle-type reaction process. After reacting for 2 hours, catalytic oxidation treatment was carried out on the waste liquid of the separator; after the treatment, it became clear and transparent, the content of ammonia nitrogen increased by 30%, the content of total phosphorus decreased by 70%, and the removal rate of COD could reach 76.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com