A method of manufacturing a flexible capacitive touch screen

A technology of capacitive touch screen and manufacturing method, which is applied in the direction of electric digital data processing, input/output process of data processing, instruments, etc., can solve the problems of high ultraviolet transmittance, great difficulty, high investment threshold, etc., and reduce the manufacturing cost. Low cost, convenient subsequent processing, and the effect of avoiding wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

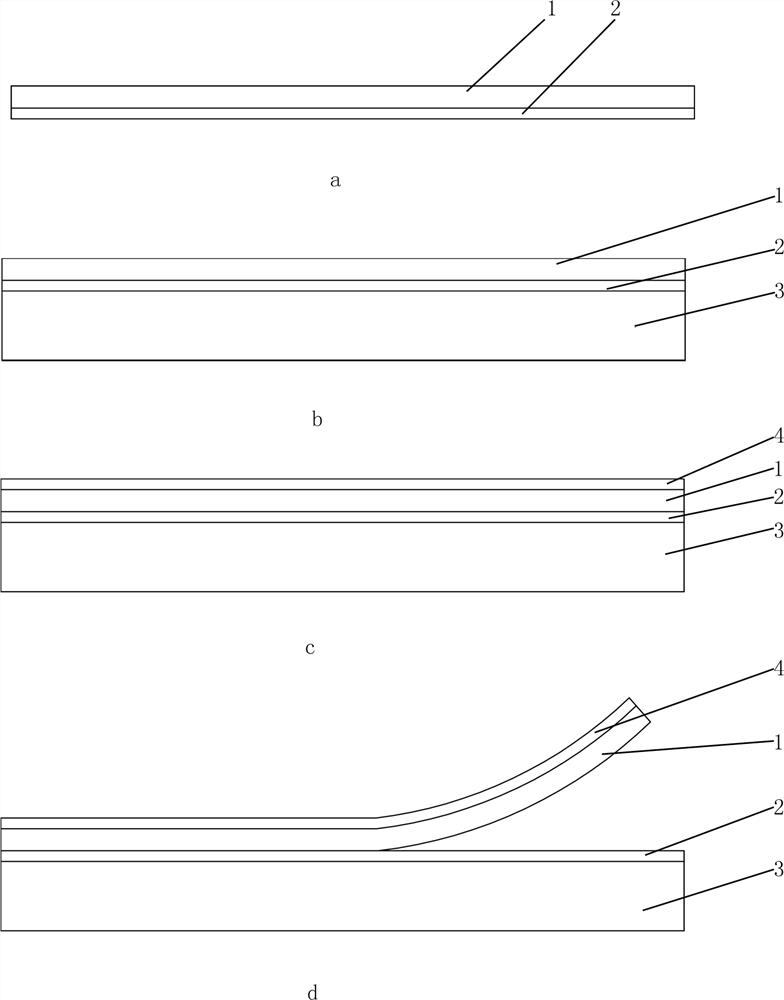

[0022] Such as figure 1 As shown, the manufacturing method of this flexible capacitive touch screen comprises the following steps:

[0023] Step (1), such as figure 1 As shown in -a, corona treatment is carried out on the inner surface of the polyimide film 1, and then the adhesive layer 2 is arranged on the inner surface of the polyimide film 1;

[0024] Step (2), such as figure 1 As shown in -b, the polyimide film 1 is pasted on the carrier plate 3 through the above-mentioned adhesive layer 2. When the polyimide film 1 is pasted, a downward direction is applied to the outer surface of the polyimide film 1. Air curtain, the width of the air curtain is greater than the width of the polyimide film 1;

[0025] Step (3), such as figure 1 As shown in -c, the touch circuit layer 4 of the capacitive touch screen is made on the polyimide film 1;

[0026] Step (4), such as figure 1 As shown in -d, the polyimide film 1 is peeled from the carrier 3 by mechanical means, and the car...

Embodiment 2

[0033] In the case that other parts are the same as in the first embodiment, the only difference is that a low-viscosity layer is provided on the carrier board 3 , and the adhesion of the low-viscosity layer is smaller than that of the adhesive layer 2 .

Embodiment 3

[0035] In the case that other parts are the same as the first embodiment, the only difference is: in step (1), corona treatment is performed on the outer surface of the carrier plate 3 , and then the adhesive layer 2 is provided on the outer surface of the carrier plate 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com