Pneumatic chemical pump

A chemical pump, pneumatic technology, applied in the field of pneumatic chemical pumps, can solve problems such as filling liquids, and achieve the effect of a wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

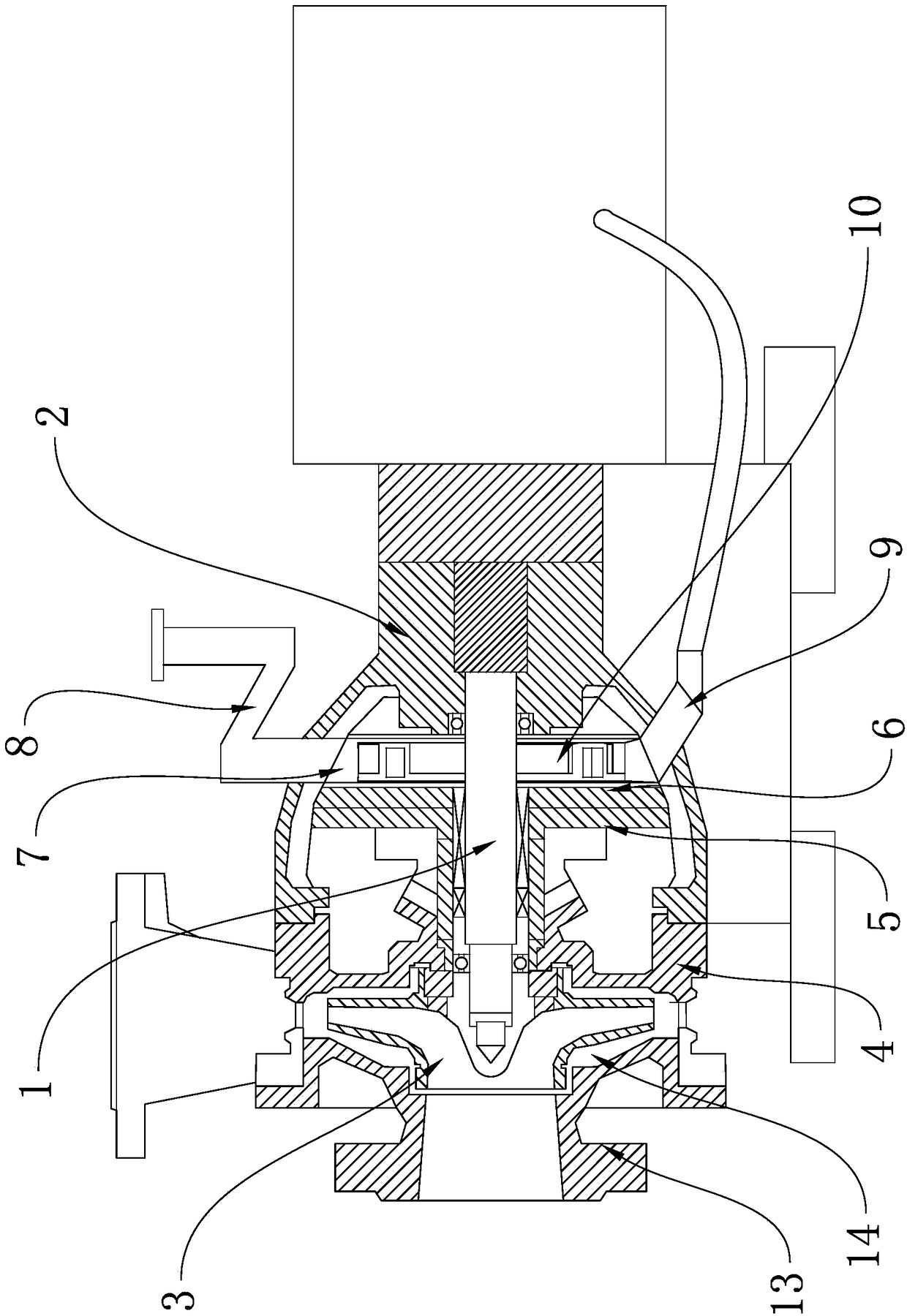

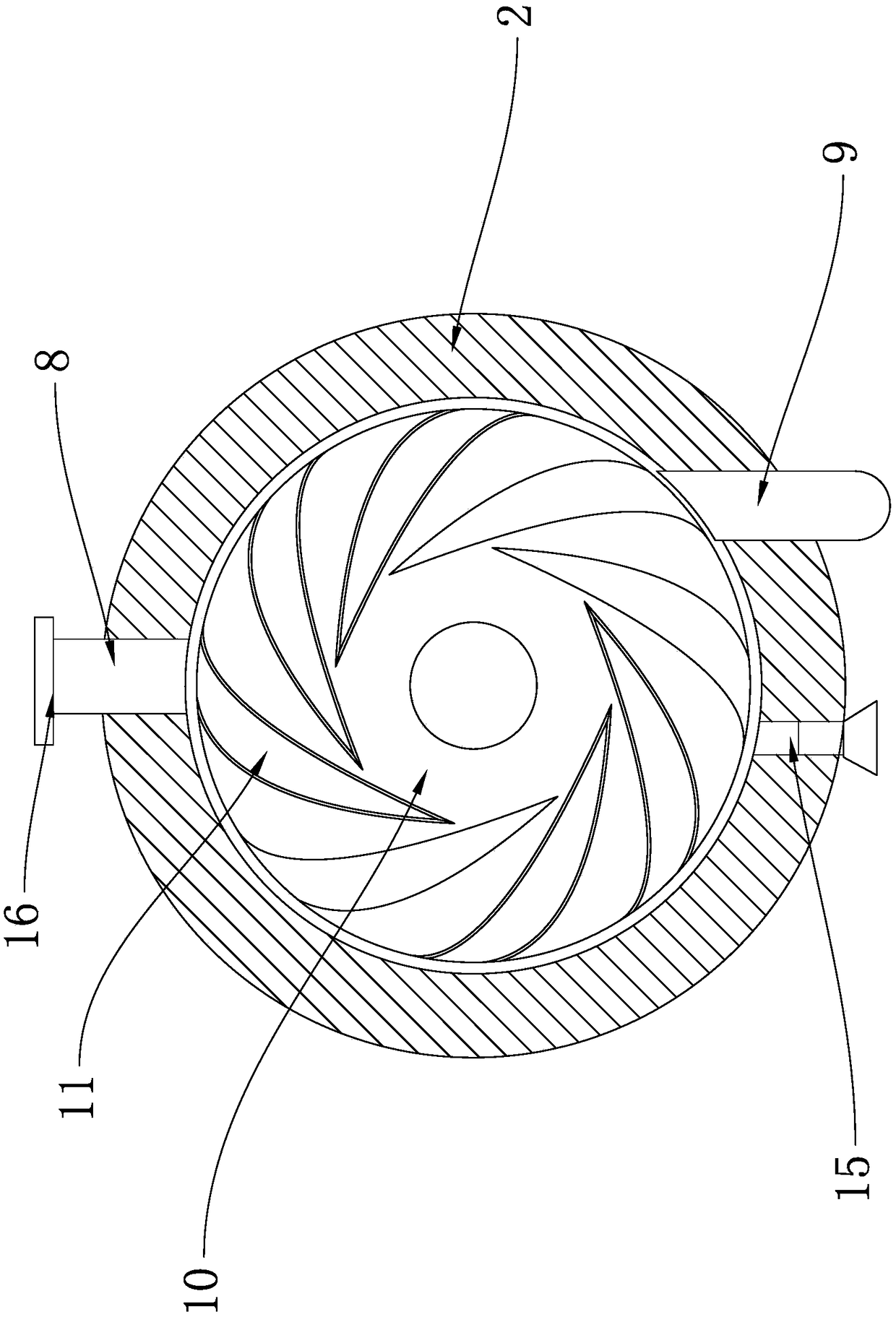

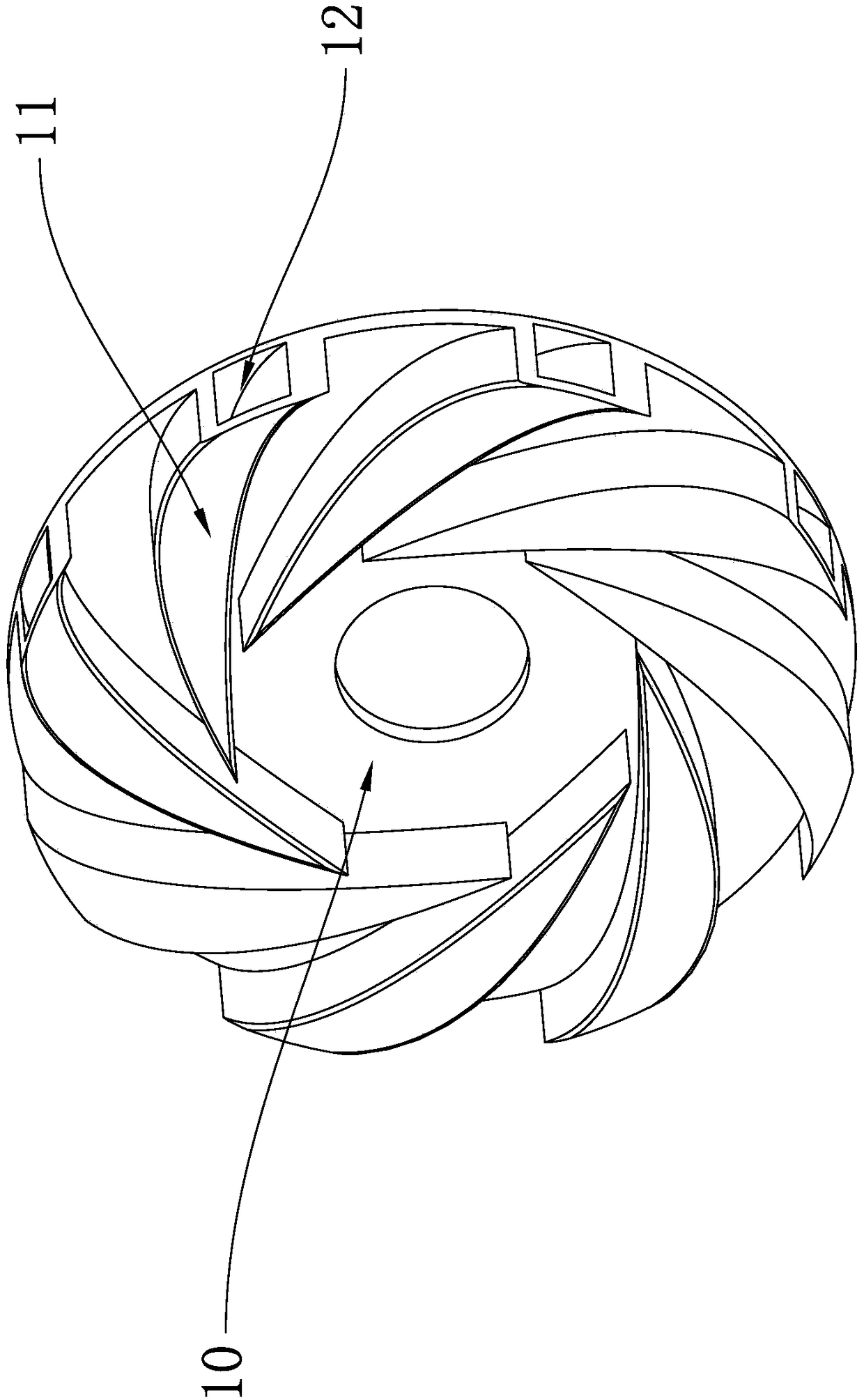

[0023] like Figure 1 to Figure 3 As shown, the pneumatic chemical pump includes a main shaft 1, a bracket 2 and an impeller 3. The impeller 3 is fixed on one end of the main shaft 1. Set in the bracket 2, the isolation sleeve 5 is fixed on the pump casing 4; the isolation sheet 6 is fixed on the isolation sleeve 5, and forms a closed chamber 7 with the bracket 2; the upper part of the bracket 2 is fixed with the cavity 7 The air outlet pipe 8 that communicates with each other, the lower part of the bracket 2 is fixed with an air intake pipe 9 that is communicated with the chamber 7, and the air inlet pipe 9 is connected to the air pump through the air pipe; The gas wheel 10 is made of fluoroplastic. The gas wheel 10 is provided with a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com