Gypsum-based exterior wall bottom-layer putty and preparation method thereof

A gypsum-based, exterior wall technology, applied in the field of building materials, can solve problems such as hollowing, peeling and shelling, and different colors, and achieve the effects of preventing flame spread, preventing temperature rise, and good fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

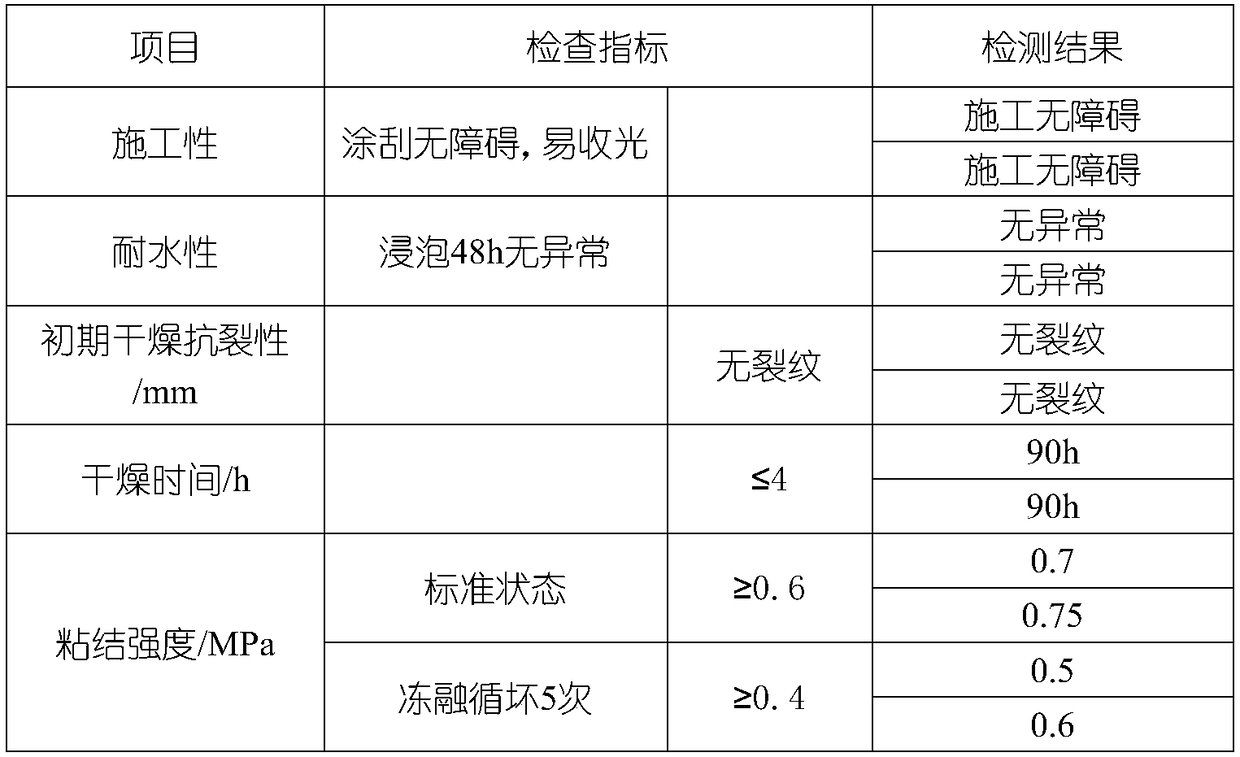

Examples

Embodiment 1

[0036] A gypsum-based outer wall putty, which is composed of the following raw materials in parts by weight: 1 kg of desulfurized gypsum powder, 1 kg of po42.5 cement, 1 kg of redispersible latex powder, 1 kg of fly ash, and 1 kg of hydroxypropyl methylcellulose , starch ether 1kg, retarder 1kg;

[0037] The preparation method of described a kind of gypsum-based exterior wall primer, comprises the following steps:

[0038] (1) Weigh the raw materials according to the corresponding proportion, mix them into the container, and stir with a hand mixer for 8 minutes;

[0039] (2) Mix the materials stirred in step (1) with water at a mass ratio of 2.5:1, mix well, let stand for 3 minutes, stir again until thickened and ready to use.

Embodiment 2

[0041] A gypsum-based external wall bottom putty, which is composed of the following raw materials in parts by weight: 1000kg of desulfurized gypsum powder, 500kg of po42.5 cement, 10kg of redispersible latex powder, 500kg of fly ash, and 5kg of hydroxypropyl methylcellulose , starch ether 3kg, retarder 3kg;

[0042] The preparation method of described a kind of gypsum-based exterior wall primer, comprises the following steps:

[0043] (1) Weigh the raw materials according to the corresponding proportion, mix them into the container, and stir for 12 minutes with a hand mixer;

[0044] (2) Mix the materials stirred in step (1) with water at a mass ratio of 3.5:1, mix well, let stand for 3 minutes, stir again until thickened and ready to use.

Embodiment 3

[0046] It consists of the following raw materials in parts by weight: desulfurized gypsum powder 500kg, po42.5 cement 350kg, redispersible latex powder 5kg, fly ash 250kg, hydroxypropyl methylcellulose 2.5kg, starch ether 1kg, retarder 1.5kg;

[0047] The preparation method of described a kind of gypsum-based exterior wall primer, comprises the following steps:

[0048] (1) Weigh the raw materials according to the corresponding proportion, mix them into the container, and stir for 10 minutes with a hand mixer;

[0049] (2) Mix the materials stirred in step (1) with water at a mass ratio of 3:1, mix well, let stand for 3 minutes, stir again until thickened and ready to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com