Emergency stop pressure sensor, safety device, and safety system

A pressure sensor and safety device technology, applied in the field of emergency stop pressure sensors, can solve the problems of difficulty in reducing injuries, detection reduction, low pressure detection sensitivity, etc., and achieve the effect of improving pressure detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will now be described with reference to the accompanying drawings. Figure 1-Figure 6 The first embodiment will be described below.

[0027] summary

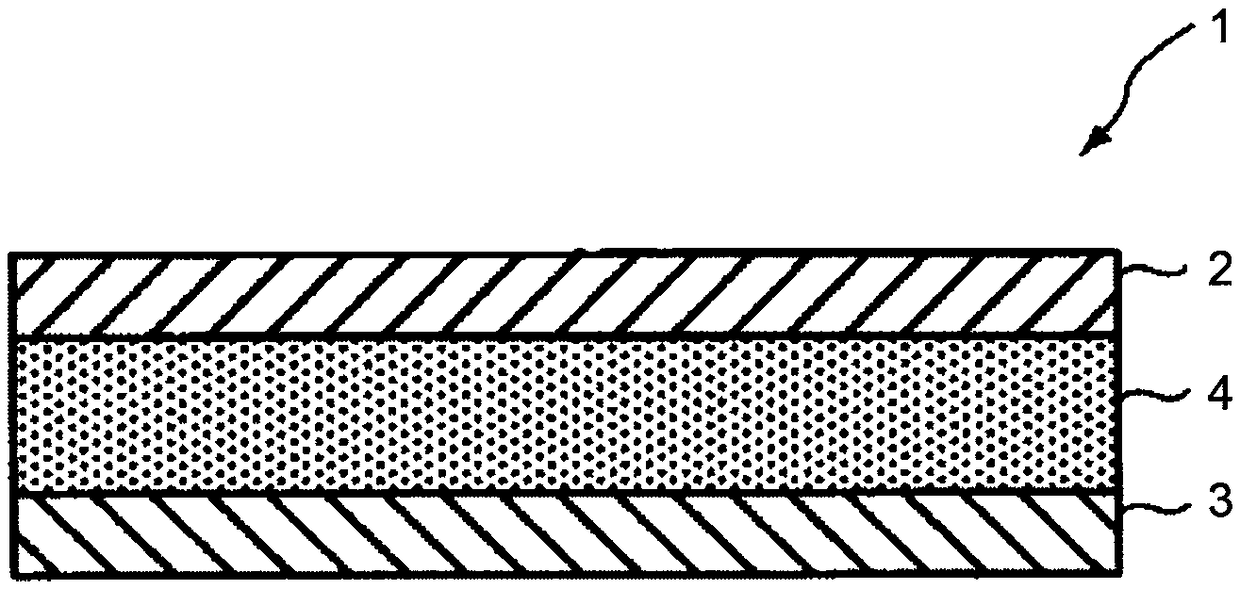

[0028] figure 1 is a schematic cross-sectional view of an element according to the present embodiment. The element 1 has a first electrode 2 and a second electrode 3 facing each other and an intermediate layer 4 provided between the first and second electrodes and formed of rubber or a rubber composition.

[0029] detail

[0030] first electrode and second electrode

[0031] The material, shape, size, and structure of the first electrode and the second electrode are not particularly specified and may be selected as appropriate according to purposes. Materials, shapes, dimensions, and structures may or may not be shared between the first and second electrodes, although sharing is more preferred. Examples of materials for the first electrode and the second electrode include metals,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com