Electrophoretic paint used for aluminum profile, preparation method thereof and aluminum profile prepared through electrophoresis

An electrophoretic paint, aluminum profile technology, applied in electrophoretic plating, electrophoretic paint, electrolytic paint, etc., can solve the problems of high energy consumption process, complex process, insufficient environmental protection and energy saving, etc., achieve high corrosion resistance, long weather resistance, reduce The effect of waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] An electrophoretic paint for aluminum profiles, the electrophoretic paint includes the following raw materials: AA: acrylic acid, MMA: methyl methacrylate, BA: butyl acrylate, HEMA: hydroxyethyl methacrylate, GMMA: glycerol monomethacrylic acid ester, TMPTMA: trimethylolpropane trimethacrylate, TMP(3EO)TMA: ethoxylated trimethylolpropane trimethacrylate and E30BADMA: ethoxylated bisphenol A dimethacrylate.

[0020] The components of the electrophoretic paint include by weight percentage: AA2-4%, MMA10-20%, BA20-30%, HEMA6-10%, GMMA6.5-12.5%, TMPTMA3-7%, TMP(3EO)TMA5 -9% and E30BADMA2.5-6.5%;

[0021] The electrophoretic paint also includes polymerization reaction buffer solvent, amino resin, TBPB: tert-butyl peroxybenzoate and BCS: chromium sulfate.

[0022] The buffering solvent is IPA: isopropanol and ECS: ethylene glycol ether.

[0023] By weight percentage, the electrophoretic paint includes 1-3% of IPA, 1-3% of ECS, 10-24% of amino resin, 0.8-1.6% of TBPB and 1.2...

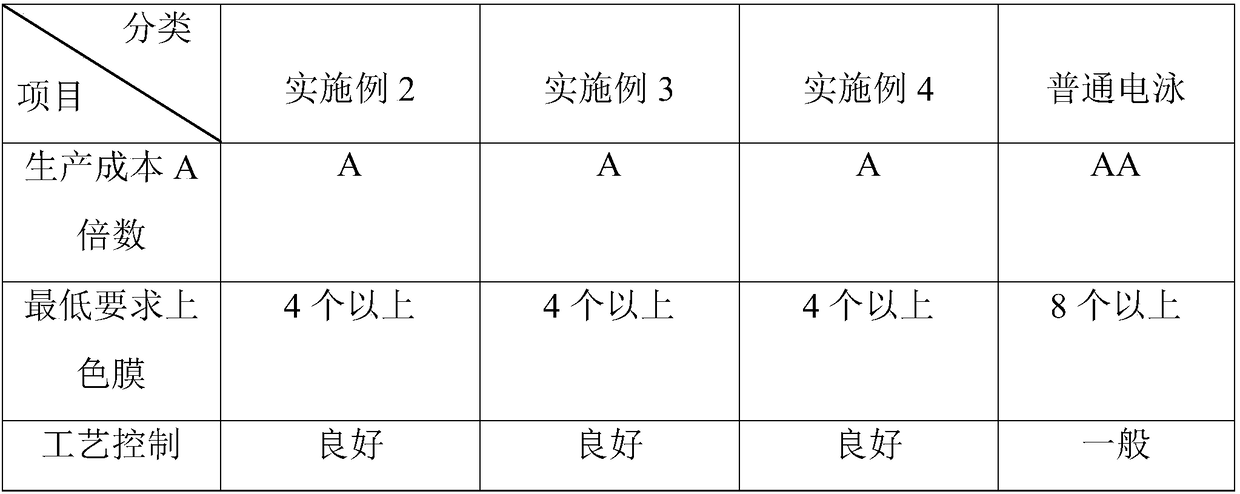

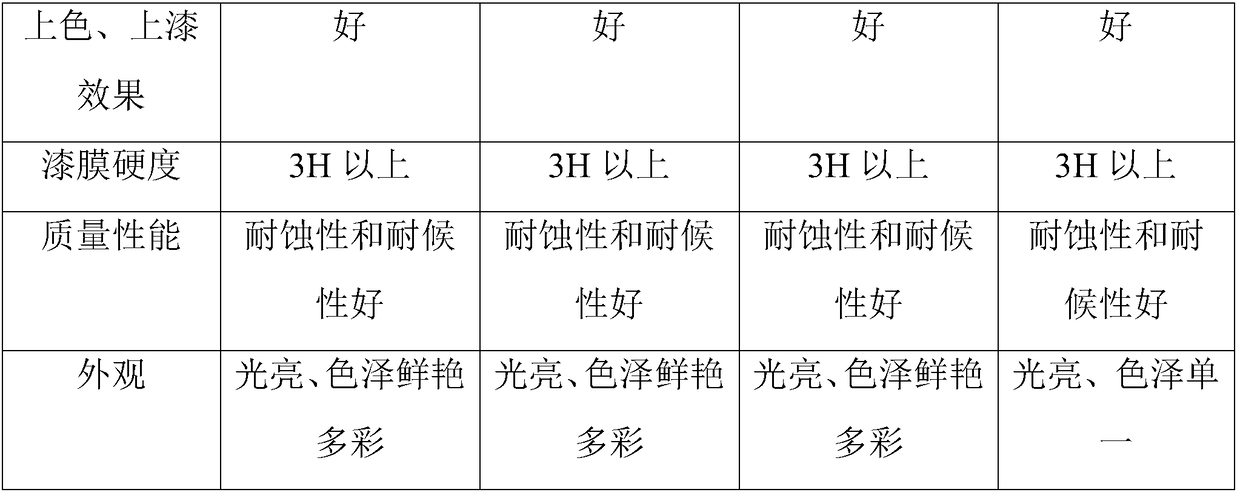

Embodiment 2

[0034] On the basis of Example 1, the present invention proposes an electrophoretic paint for aluminum profiles. The electrophoretic paint includes the following raw materials by weight percentage: AA3%, MMA 15%, BA 25%, HEMA8%, GMMA9.5%, TMPTMA5%, TMP(3EO)TMA7%, E30BADMA4.5%, IPA1.5%, ECS1.5%, amino resin 17%, TBPB1.2% and BCS1.8%.

[0035] A preparation method for electrophoretic paint for aluminum profiles, comprising the following steps:

[0036] 1) Add AA, MMA, BA, HEMA, GMMA, TMPTMA, TMP(3EO)TMA, E30BADMA, and BCS into the reaction vessel with the corresponding proportion of IPA and ECS according to the corresponding proportion, and in the corresponding proportion of TBPB Under the catalysis of , fully stir the reaction for 12h;

[0037] 2) When the temperature in step 1) is lowered to 65° C., add DMAE: dimethylaminoethanol to the reaction vessel for saponification reaction to become water-soluble;

[0038] 3) Add an amino resin cross-linking agent to step 2), and then...

Embodiment 3

[0040] On the basis of Example 1, the present invention proposes an electrophoretic paint for aluminum profiles. The electrophoretic paint includes the following raw materials by weight percentage: AA2%, MMA 10%, BA 20%, HEMA6%, GMMA6.5%, TMPTMA7%, TMP(3EO)TMA9%, E30BADMA6.5%, IPA3%, ECS3%, amino resin 24%, TBPB 1% and BCS2%.

[0041] A preparation method for electrophoretic paint for aluminum profiles, comprising the following steps:

[0042] 1) Add AA, MMA, BA, HEMA, GMMA, TMPTMA, TMP(3EO)TMA, E30BADMA, and BCS into the reaction vessel with the corresponding proportion of IPA and ECS according to the corresponding proportion, and in the corresponding proportion of TBPB Under the catalysis of the catalyst, fully stir the reaction for 8h;

[0043]2) When the temperature in step 1) is lowered to 50° C., add DMAE: dimethylaminoethanol to the reaction vessel for saponification reaction to become water-soluble;

[0044] 3) Add amino resin cross-linking agent to step 2), and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com