Anode processing process for die casting aluminum alloy and oxidation device of die casting aluminum alloy

A casting aluminum alloy and oxidation device technology, which is applied in anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problem of low corrosion resistance of aluminum alloy anodic oxidation film, uneven electrolyte concentration and temperature, film layer Low microhardness and other problems, to achieve the effect of shortening oxidation time, improving oxidation efficiency and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Hereinafter, the present invention will be further described in detail with reference to the examples and drawings, but the implementation of the present invention is not limited thereto.

[0027] The specific implementation process of the present invention is as follows:

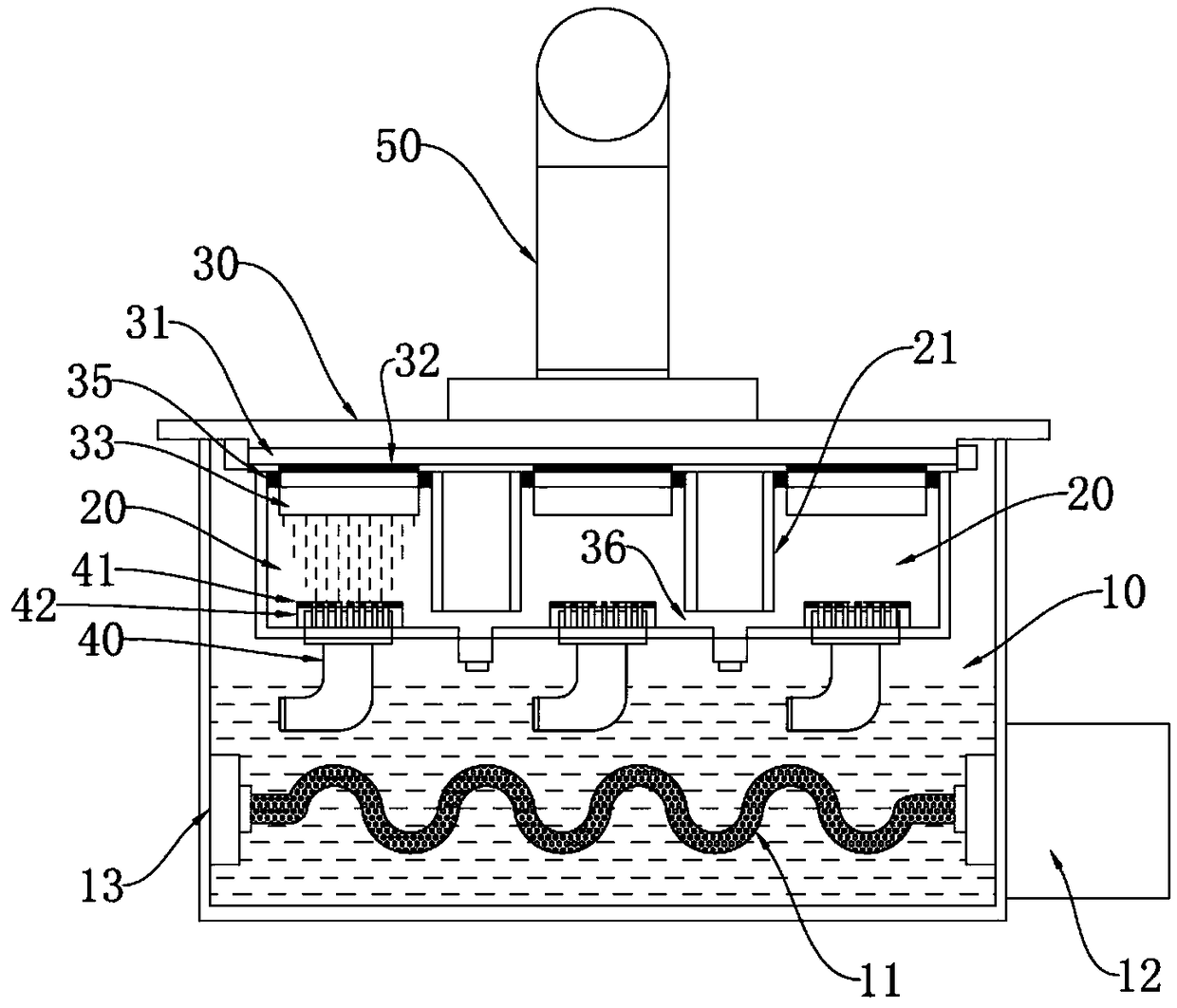

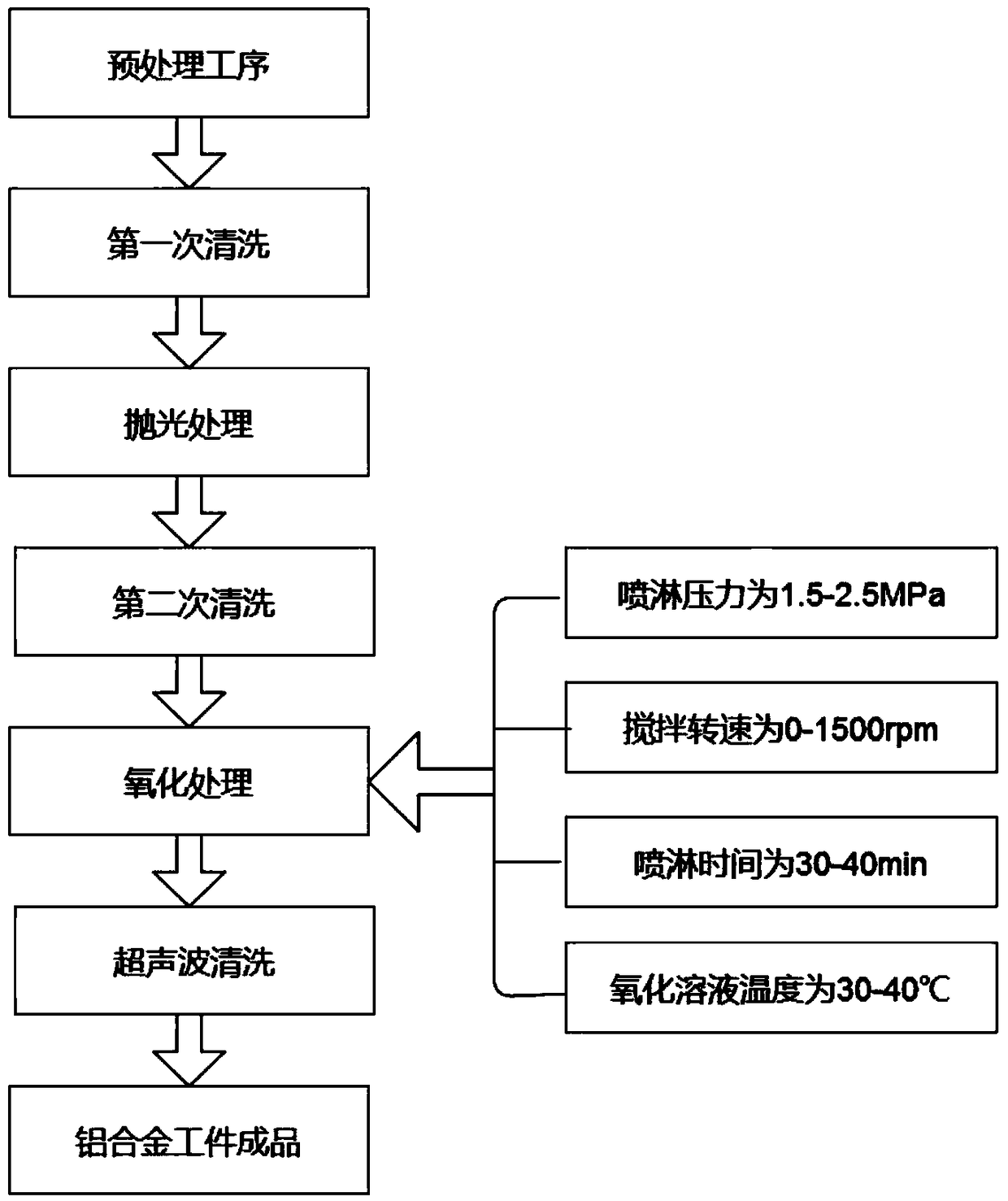

[0028] Such as figure 1 As shown, an anode treatment process for die-casting aluminum alloy includes the following steps:

[0029] The first step, pretreatment process: grinding the die-cast aluminum alloy;

[0030] The second step, the first cleaning: Put the polished die-cast aluminum alloy workpiece in sodium hydroxide solution for alkaline washing, rinse the alkaline-washed die-cast aluminum alloy workpiece with tap water, and rinse until the pH of the washing solution is 5- 6;

[0031] The third step, polishing treatment: put the die-cast aluminum alloy workpiece after the first cleaning into the polishing solution for chemical polishing, the polishing temperature is 68-73℃, and the polishing time is 45-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap