Compact shelving bottom rack bearing beam and manufacturing method thereof

A technology of compact racks and underframes, applied in the field of compact racks, can solve problems such as large installation errors, axial and/or radial deviations, and jamming, so as to improve operational reliability and stability, high transmission coordination accuracy, The effect of simple installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the technical solutions of the present invention, the present invention will be further described by the following embodiments in conjunction with the accompanying drawings.

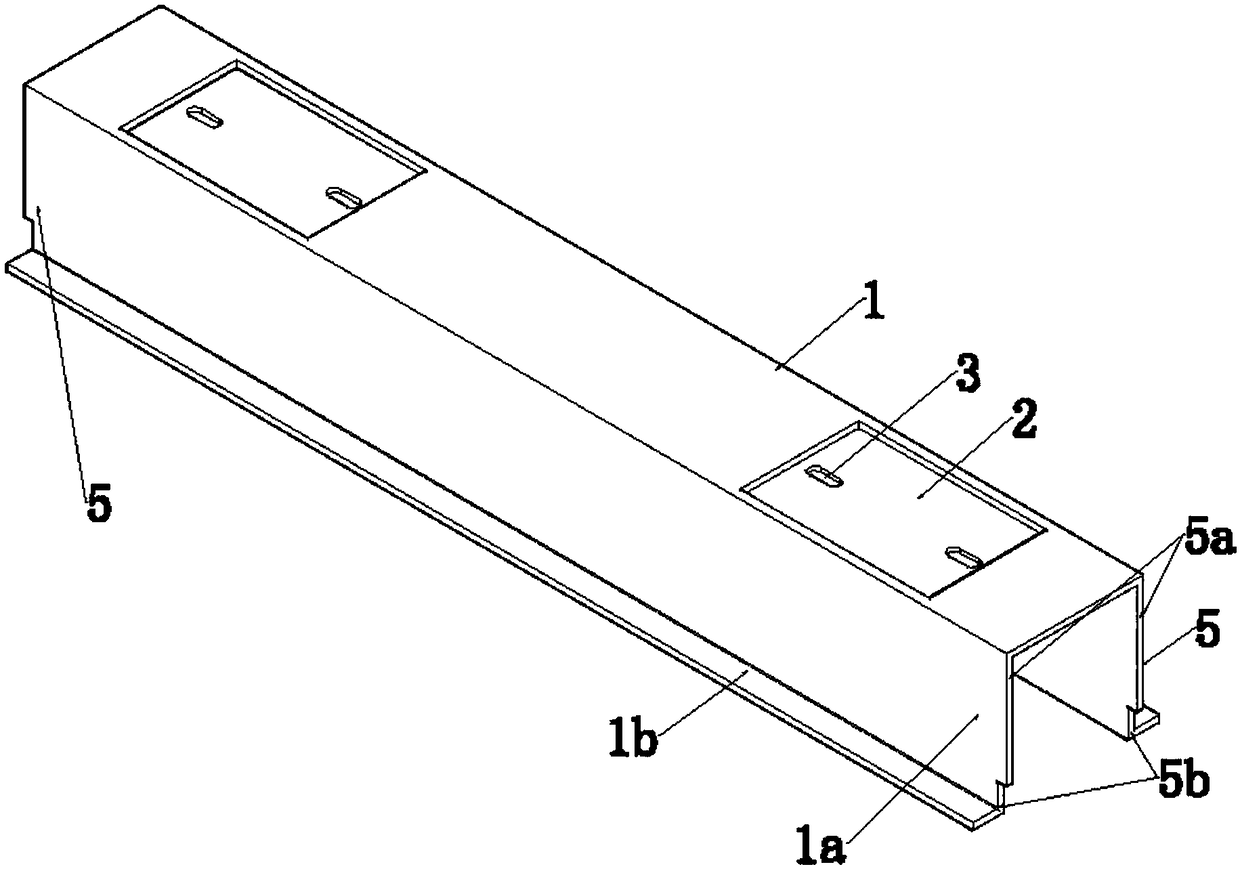

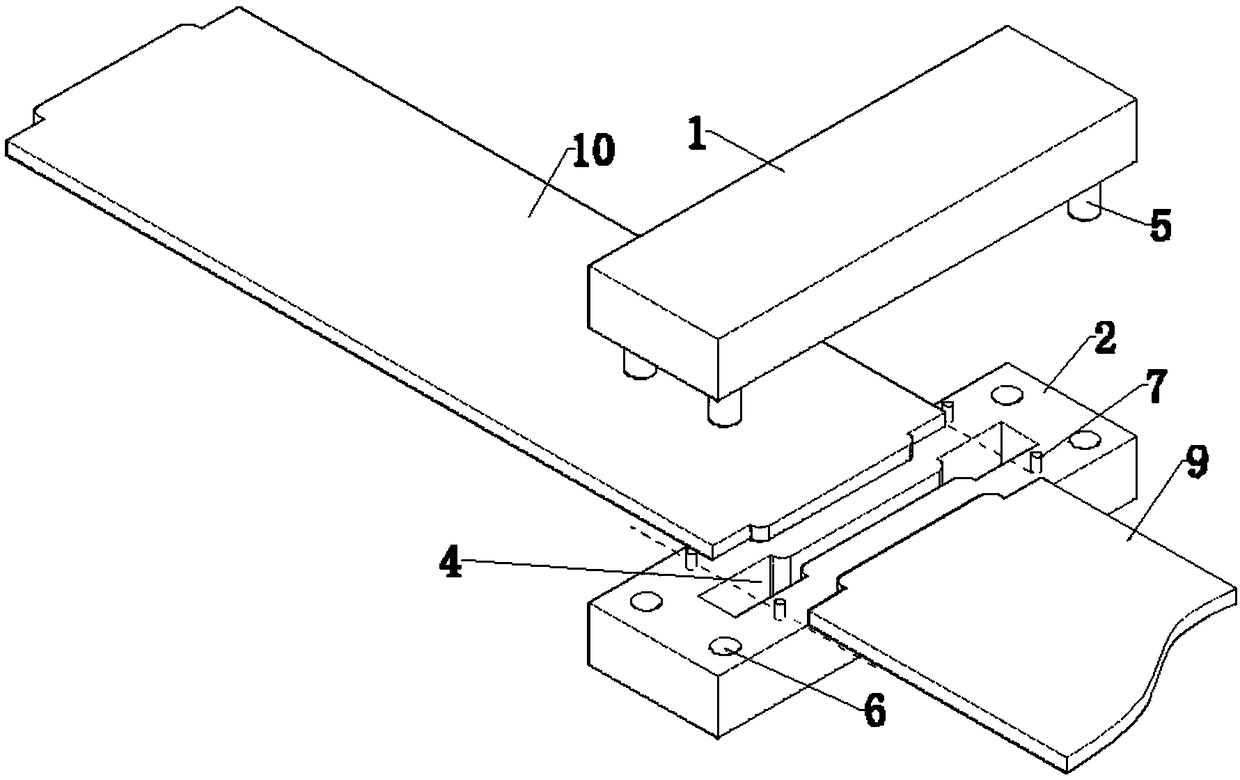

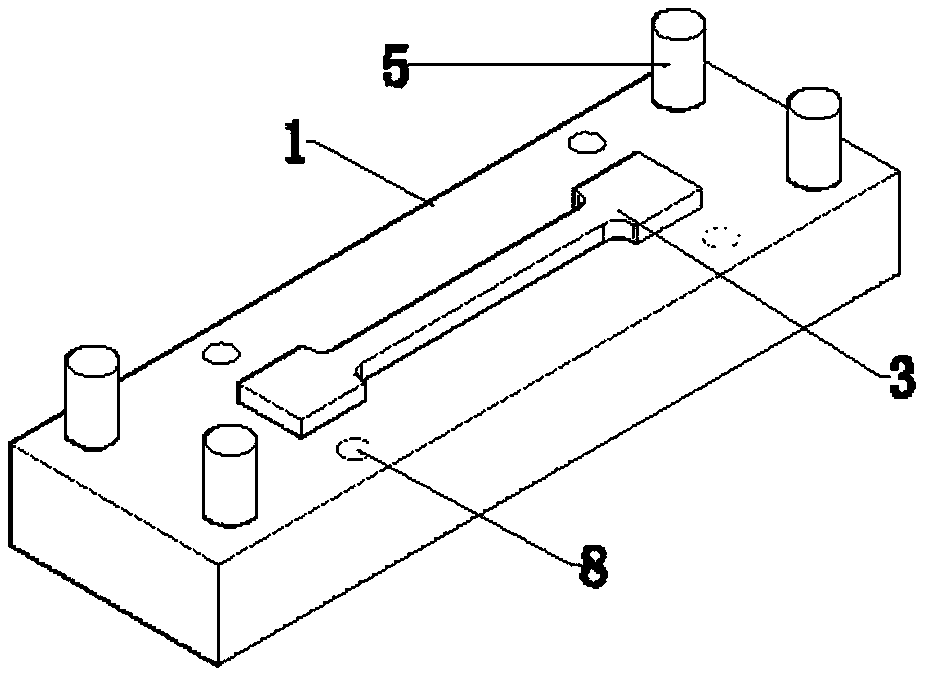

[0014] Such as Figure 1-4 As shown, the underframe bearing beam of the compact shelf in this example includes an open frame bar 1 whose cross-sectional shape is a rectangular open frame. Its rectangular open frame bar 1 includes an open frame body 1a with an open opening on one side (lower side), and the end faces of the open frame body 1a opposite to the opening, respectively protruding outwards. For the wing plate 1b, the open frame body 1a and the wing plate 1b are formed by multiple times of right-angle bending of the punched and processed workpiece plates with convex end portions 5 respectively provided at opposite ends. Its convex end 5 consists of the opposite side end faces of the open frame body 1a of the open frame type bar on the side of the open opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com