Sectional material cutting and feeding mechanism

A technology of feeding mechanism and feeding mechanism, which is applied in metal processing and other directions, can solve the problems of low profile cutting efficiency, high labor cost, and poor precision, and achieve the effects of reducing the time of manual intervention, improving quality, and improving feeding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure of the present invention will be further described below in conjunction with the accompanying drawings and preferred specific embodiments of the present invention.

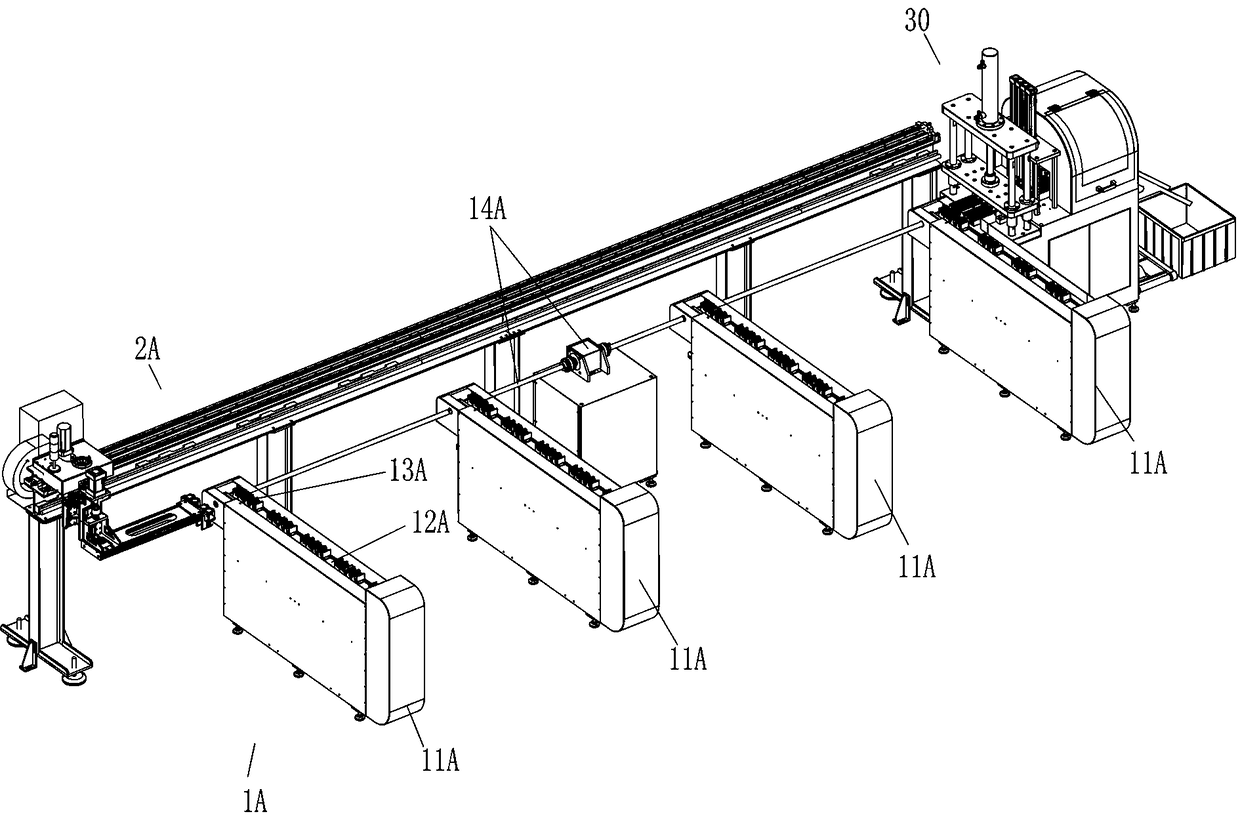

[0022] refer to figure 1 and figure 2 As shown in , the profile cutting and feeding mechanism of the present invention includes: a discharging mechanism 1A and a feeding mechanism 2A; in this embodiment, four profiles can be sent to the cutting mechanism 30 at the same time to complete punching and punching chamfering and profile cut off.

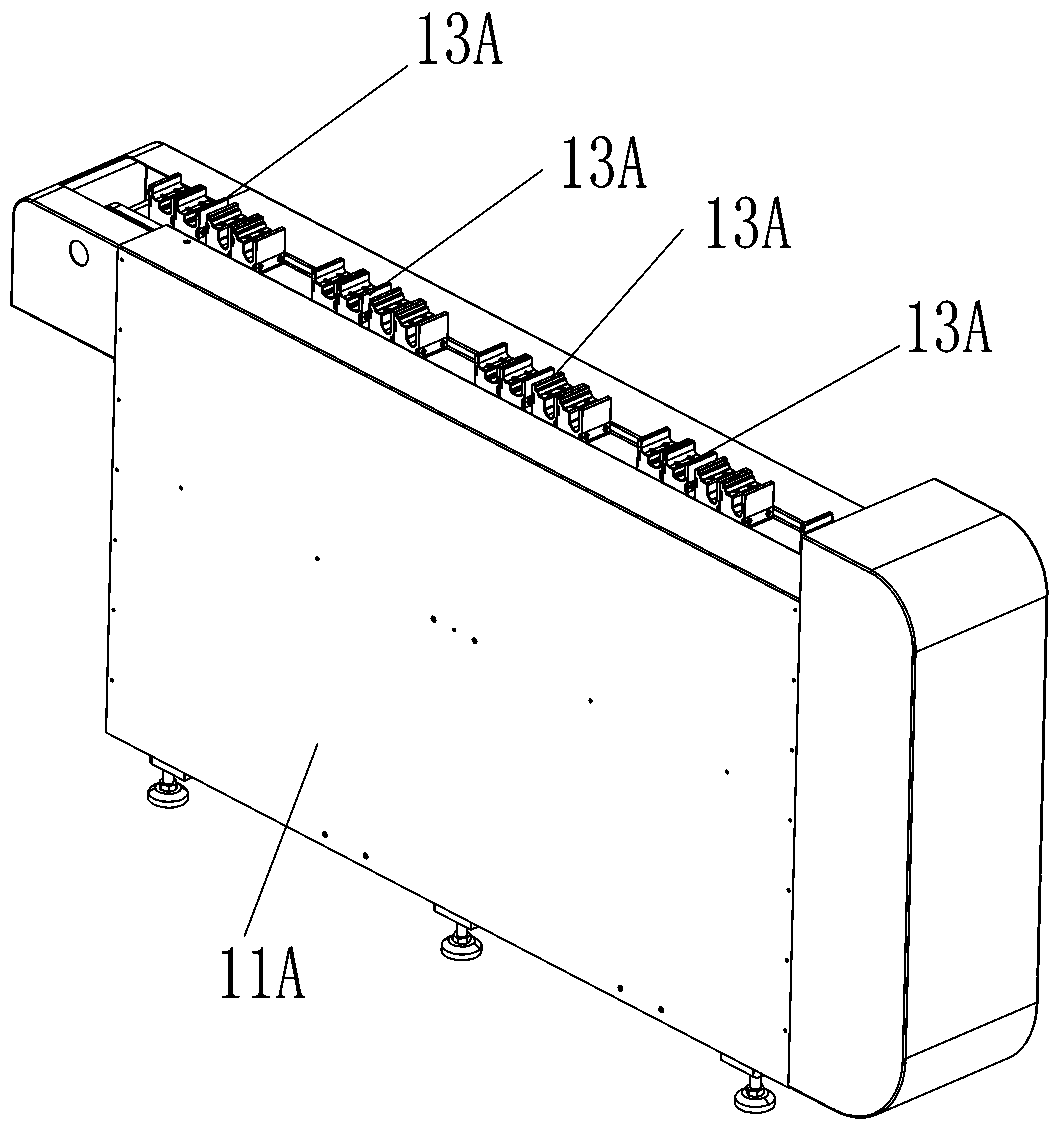

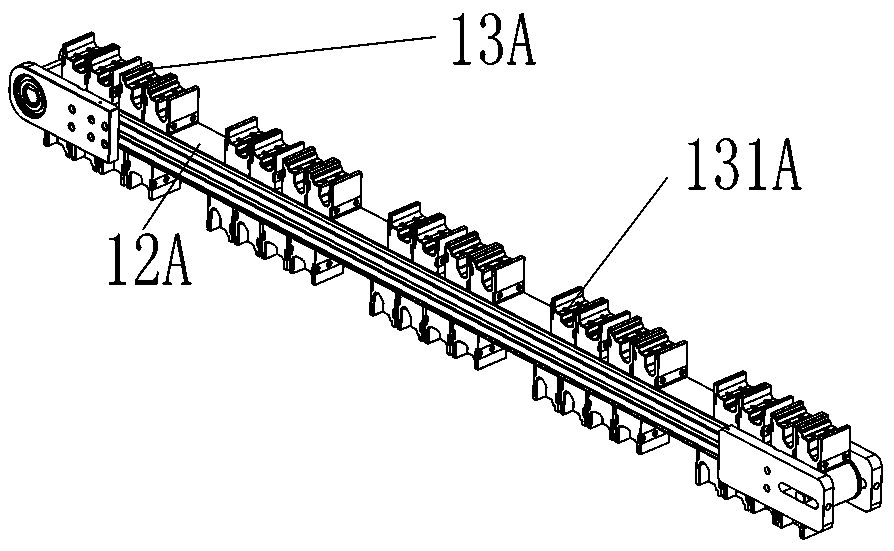

[0023] The discharge mechanism 1A includes more than two groups of discharge brackets 11A arranged side by side, the discharge bracket 11A is provided with a conveyor belt mechanism 12A that is transmitted to the direction of the feed mechanism 2A, and the conveyor belt mechanism 12A is fixedly installed with two or more groups of supply profiles. Placed profile jig 13A; each conveyor belt mechanism 12A is connected with a conveyor belt drive mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com