Crab trap automatic circling and welding integrated machine

An all-in-one machine and crab cage technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of not having automatic crab cage equipment, hindering the automatic production of crab cages, and laborious and laborious problems, so as to achieve a simplified structure, labor saving, Guarantee the effect of the material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

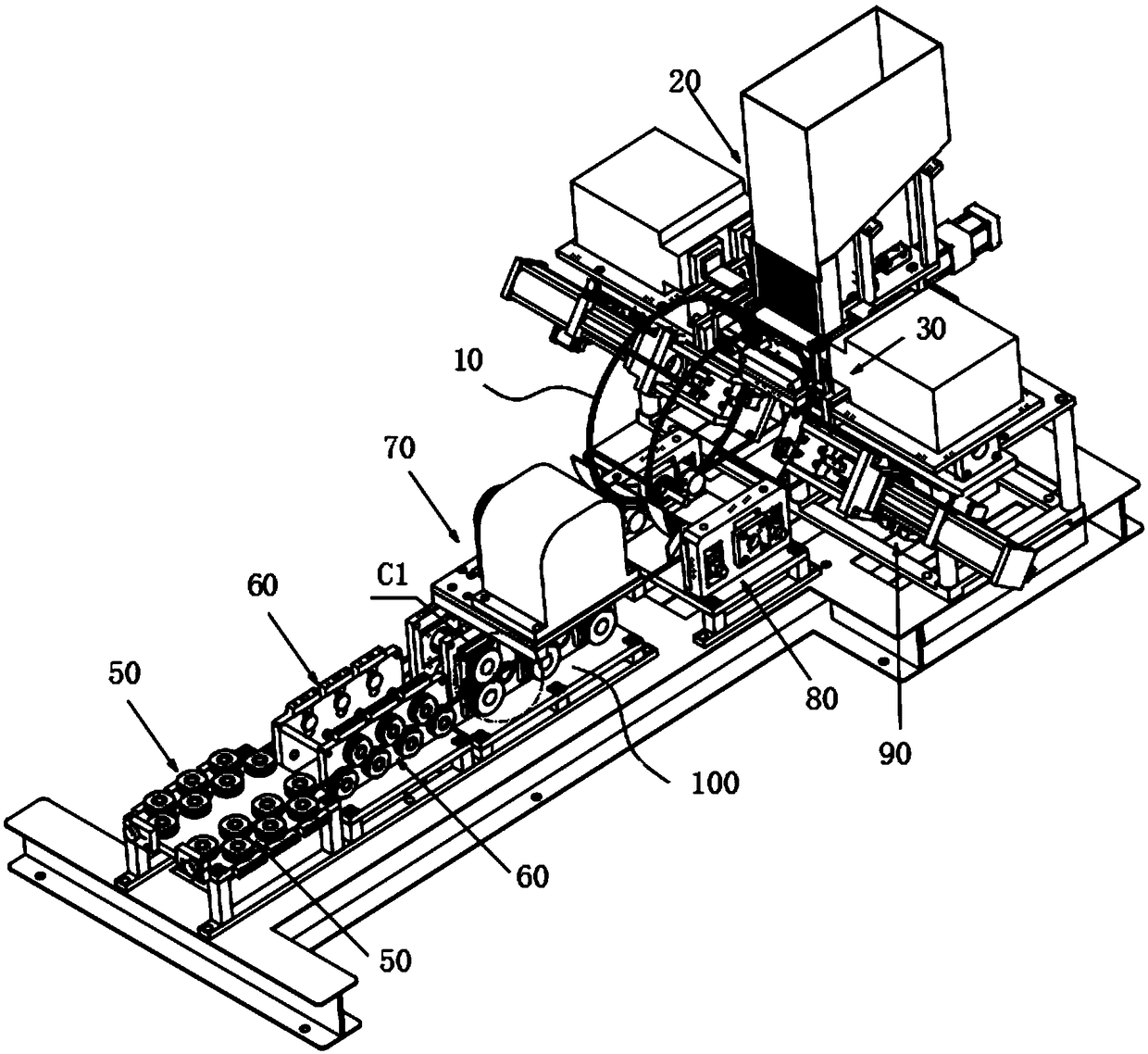

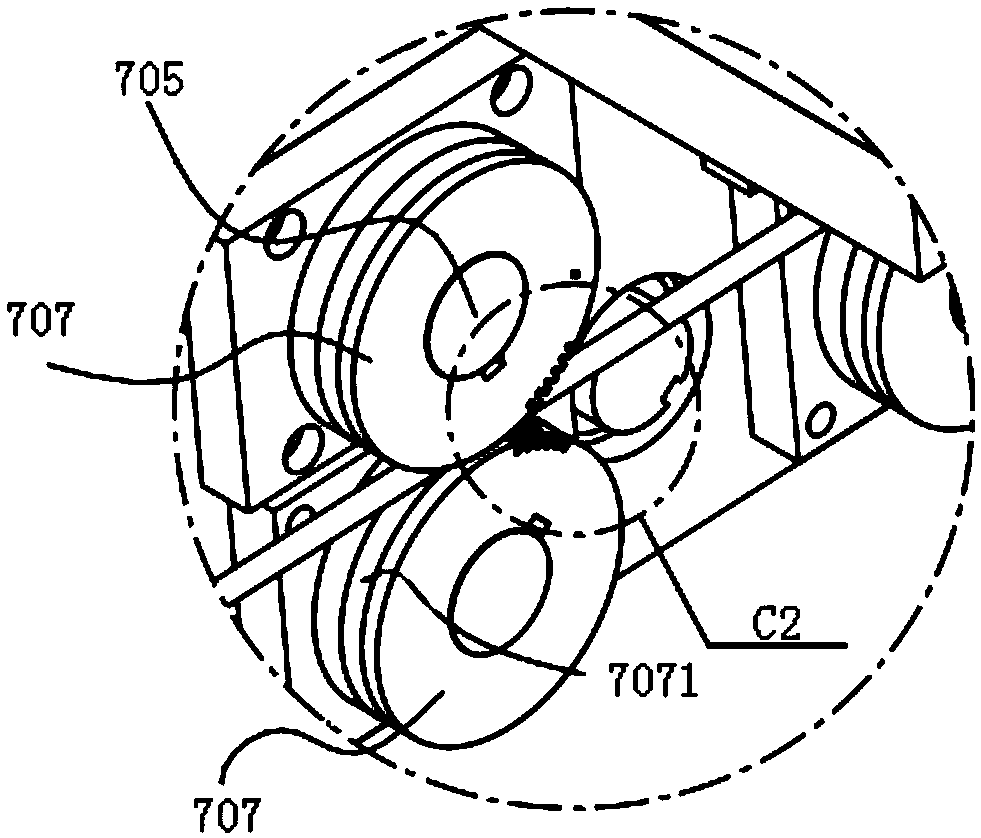

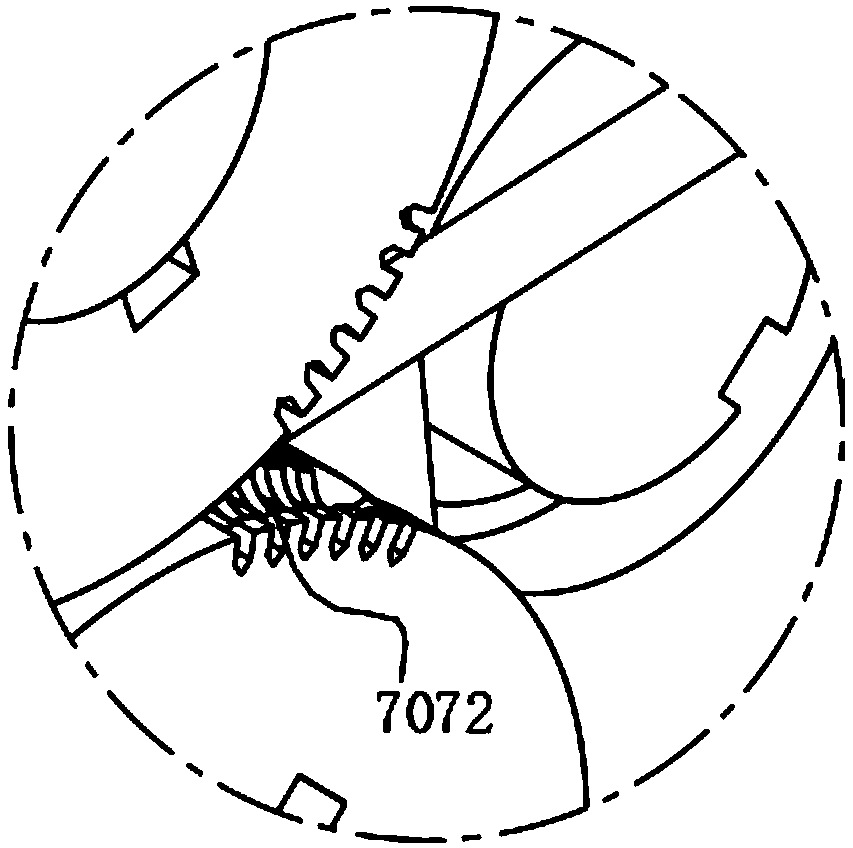

[0050] Embodiment: a kind of crab cage automatic welding all-in-one machine, such as figure 1 , Figure 4 and Image 6 As shown, the crab cage 10 includes two frame rings 101 and a plurality of vertical ribs 102, the vertical ribs 102 are arranged at intervals along the circumference of the frame ring and the two ends of each vertical rib are all welded to the frame ring 101, The feeding end of the steel bar that defines the frame ring is left, and the all-in-one machine includes a frame 100 and a horizontal straightening mechanism 50, a vertical straightening mechanism 60, a transmission mechanism that are arranged on the frame 100 from left to right Mechanism 70, ring-making mechanism 80, cutting mechanism 90 and automatic blanking and welding device, the steel bars for frame-making circle can pass through described horizontal straightening mechanism 50, described vertical straightening mechanism successively under the drive of described transmission mechanism. Straight me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com