Preparation method of toughened pressure-resistant ablation-resistant material

An ablation-resistant and toughening technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of poor high-temperature compression resistance, high brittleness of phenolic resin, high molding shrinkage and difficult processing, etc. The effect of improving thermal insulation performance, large thermal conductivity, and increasing heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

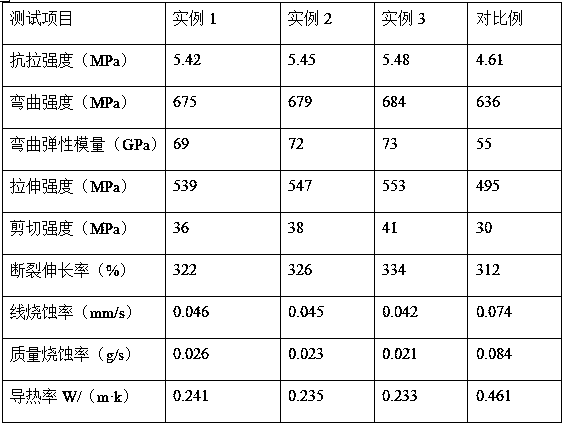

Examples

Embodiment Construction

[0023] Take 150-200mL of methyl silicone oil into a three-necked flask equipped with a thermometer and a reflux device, move the three-necked flask into a sand bath under nitrogen protection, control the temperature of the sand bath at 420-430°C, keep warm for 1-2 hours, then heat up To 460 ~ 480 ° C, continue to heat the reaction for 40 ~ 50 minutes, naturally cool to room temperature after the reaction to obtain the product; add 200 ~ 300mL xylene to the above product, stir and mix for 10 ~ 15 minutes and then filter to obtain the filtrate, which is transferred to In a rotary evaporator, concentrate by rotary evaporation at 80-90°C for 40-50 minutes to obtain a concentrated solution. Take 30-40 g of zirconium boride and add it to a pulverizer to grind for 30-40 minutes to obtain zirconium boride powder. The zirconium boride powder , concentrated solution, 100-200mL deionized water were added into a beaker, and after stirring and mixing for 15-20 minutes, a binder was obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat flux | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com