Heat-conducting insulation casting glue

A technology of heat conduction insulation and potting glue, which is applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve problems such as poor insulation performance, and achieve the effects of improving insulation performance, improving fluidity, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

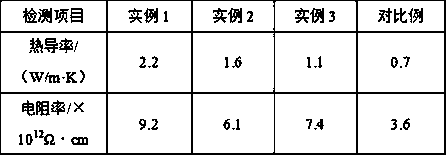

Examples

example 1

[0029] Mix active silicon micropowder and water at a mass ratio of 1:20, and ultrasonically disperse at a frequency of 55kHz for 25 minutes to obtain a silicon micropowder dispersion. Mix the silica micropowder dispersion with a silane coupling agent at a mass ratio of 10:3. After stirring and mixing for 60 minutes at a temperature of 45°C and a rotational speed of 600r / min, the pretreated microsilica powder dispersion was obtained, and the pretreated microsilica powder dispersion and the block copolymer were mixed in a beaker at a mass ratio of 10:3. And add the butanol of 0.12 times of quality of pretreatment silicon micropowder dispersion liquid in the beaker, the organic solvent of 0.08 times of quality of pretreatment silicon micropowder dispersion liquid and the sodium lauryl sulfate of 0.03 times of quality of pretreatment silicon micropowder dispersion liquid, at temperature After stirring and mixing for 60 minutes at 50°C and a rotating speed of 400r / min, filter to obt...

example 2

[0031] Mix active nano-alumina and absolute ethanol in a four-necked flask at a mass ratio of 1:28, and add orthosilicate ethyl 3 times the mass of activated nano-alumina and 0.4 times the mass of activated nano-alumina to the four-necked flask silane coupling agent, nitrogen gas was passed into the four-necked flask at a rate of 12mL / min, and the temperature was 45°C, and the rotation speed was 400r / min. After stirring and mixing for 40min, the alumina mixture was obtained. Under the condition of nitrogen, add dropwise ammonia water with a mass fraction of 25% of 0.4 times the mass of the alumina mixture to the alumina mixture at a rate of 3mL / min, and stir for 5 hours at a temperature of 45°C and a rotation speed of 350r / min. Afterwards, vacuum filtration to obtain the pretreated filler, which was washed 8 times with absolute ethanol, and dried for 40 minutes at a temperature of 70°C to obtain the filler, and the filler and isocyanate were mixed in a mass ratio of 1:4 In a f...

example 3

[0033]Mix active silicon micropowder and water at a mass ratio of 1:20, and ultrasonically disperse at a frequency of 55kHz for 25 minutes to obtain a silicon micropowder dispersion. Mix the silica micropowder dispersion with a silane coupling agent at a mass ratio of 10:3. After stirring and mixing for 60 minutes at a temperature of 45°C and a rotational speed of 600r / min, the pretreated microsilica powder dispersion was obtained, and the pretreated microsilica powder dispersion and the block copolymer were mixed in a beaker at a mass ratio of 10:3. And add the butanol of 0.12 times of quality of pretreatment silicon micropowder dispersion liquid in the beaker, the organic solvent of 0.08 times of quality of pretreatment silicon micropowder dispersion liquid and the sodium lauryl sulfate of 0.03 times of quality of pretreatment silicon micropowder dispersion liquid, at temperature After stirring and mixing for 60 minutes at 50°C and a rotating speed of 400r / min, filter to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com