Polyaniline coated biological carbon material, and application thereof in preparation of solid alkali

A bio-carbon material, polyaniline technology, which is applied in liquid carbon-containing fuel, reaction preparation of ester group and hydroxyl group, fuel and other directions, can solve problems such as equipment corrosion and environmental pollution, and achieve the effect of easy separation and high catalytic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] Example 1

[0032] (1) Take dried sweet potato leaves (400g), heat it to 600 degrees under the protection of nitrogen, and after carbonization for 6 hours, cool to room temperature naturally to obtain bio-carbon material;

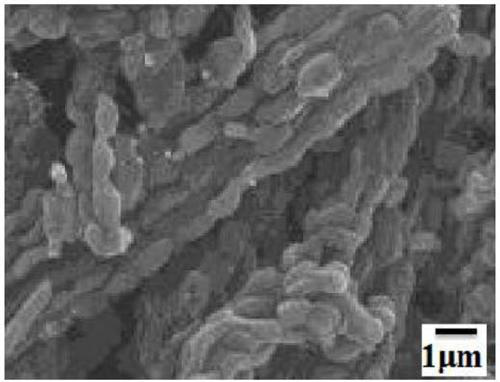

[0033] (2) Take the biocarbon material (10g) obtained in step (1) and soak it in hydrochloric acid solution (1.0mol / L, 150mL) ultrasonic (30kHz) for 5 hours, add aniline (5mL), add ammonium persulfate under ice bath The solution (0.5mol / L, 100mL), continue to react in an ice bath for 10h, filter, precipitate, wash, and dry to obtain polyaniline-coated biological carbon material (hereinafter referred to as product a).

Example Embodiment

[0034] Example 2

[0035] (1) Take dried sweet potato leaves (400g), heat up to 700 degrees under the protection of nitrogen, and after carbonization for 5 hours, cool to room temperature naturally to obtain bio-carbon material;

[0036] (2) Take the biological carbon material (10g) obtained in step (1) and soak it in hydrochloric acid solution (2.0mol / L, 100mL) ultrasonic (40kHz) for 4 hours, add aniline (5mL), add ammonium persulfate under ice bath The solution (1.0mol / L, 75mL), continue to react in an ice bath for 6h, filter, precipitate, wash, and dry to obtain polyaniline-coated biological carbon material (hereinafter referred to as product b).

Example Embodiment

[0037] Example 3

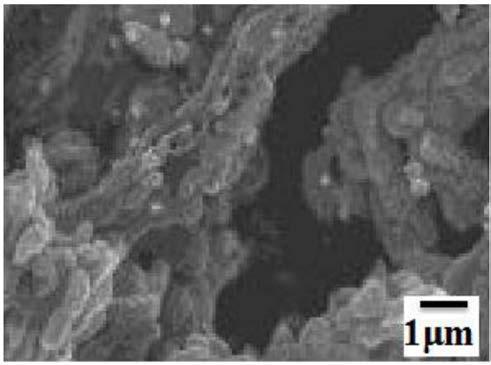

[0038] Take product a (4g) and KF (4g), K 2 CO 3 (12g) After mixing and ball milling for 6 hours, wash with water and absolute ethanol successively, and vacuum dry at 90°C for 24 hours to obtain polyaniline-coated biological carbon material loaded with alkali (hereinafter referred to as product A).

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap