Super-hydrophobic coating for oil-water separation and preparation method thereof

A super-hydrophobic coating, oil-water separation technology, applied in separation methods, filtration separation, liquid separation, etc., can solve the problems of increasing material processing costs, environmental hazards, etc., to promote the promotion of environmental friendliness, easy repair, and reduce waste disposal. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

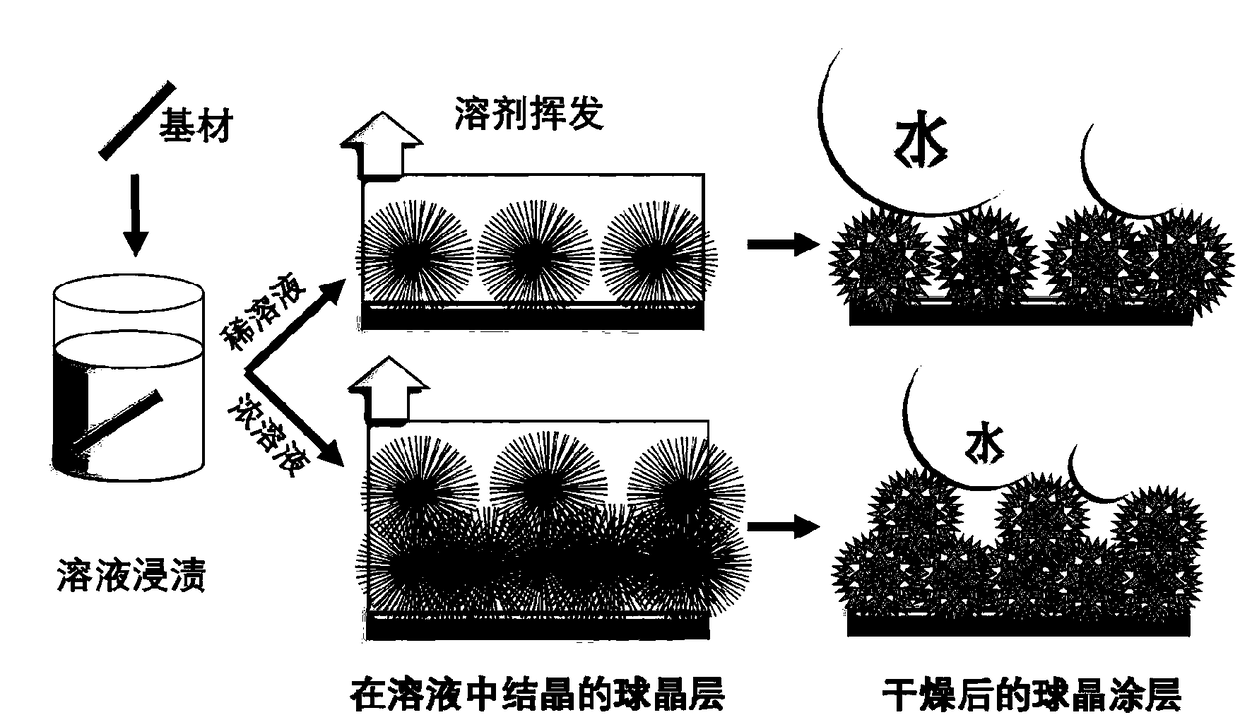

Method used

Image

Examples

Embodiment 1

[0025] A superhydrophobic coating for oil-water separation, its preparation process is as follows:

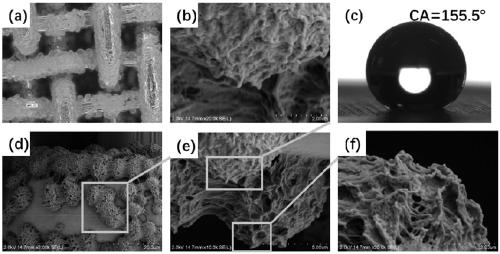

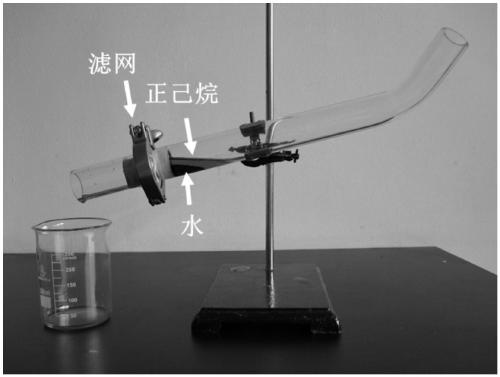

[0026] Weigh 5 grams of hydrogenated castor oil, heat and dissolve it in 95 grams of absolute ethanol to obtain a 5% hydrogenated castor oil ethanol solution, keep the solution temperature at 45 ° C, completely soak the 400-mesh stainless steel filter in the solution, take it out and place it in a clean Dry on a glass plate to obtain a stainless steel filter covered with a superhydrophobic coating. Filter surface topography visible figure 2 , the static contact angle of water droplets on the filter screen surface is 155.5°, and the contact angle of n-hexane on the filter screen surface is ~0°. The 20ml mixture of n-hexane and water can pass through image 3 The device completed the separation within 5 minutes, and the yield of n-hexane after separation was 99.6%. The mixture was separated fifty times, and the static contact angle of water droplets on the surface of the filte...

Embodiment 2

[0028] A superhydrophobic coating for oil-water separation, its preparation process is as follows:

[0029] Weigh 8 grams of hydrogenated castor oil, heat and dissolve it in 92 grams of absolute ethanol to obtain an 8% hydrogenated castor oil ethanol solution, keep the solution temperature at 50 ° C, completely soak the industrial 747 polyester fiber filter cloth in the solution, take it out and place it flat Dry it on a clean glass plate to obtain a filter cloth covered with a superhydrophobic coating. The surface morphology of the filter cloth is visible Figure 4 , the static contact angle of water droplets on the screen surface is 156.5°, and the contact angle of liquid paraffin on the filter cloth surface is ~0°. Each 20ml mixture of liquid paraffin and water can pass through the funnel ( Figure 5 ) separated in 5 minutes, and the yield of liquid paraffin after separation was 99.5%, and the mixture was repeatedly separated thirty times, and the static contact angle of ...

Embodiment 3

[0031] A superhydrophobic coating for oil-water separation, its preparation process is as follows:

[0032] Weigh 4 grams of hydrogenated castor oil, heat and dissolve it in 96 grams of absolute ethanol to obtain a 4% hydrogenated castor oil ethanol solution, keep the solution temperature at 40 ° C, completely soak the 200-mesh nylon filter in the solution, take it out and place it in a clean Dry on a glass plate to obtain a nylon filter covered with a superhydrophobic coating. Filter surface topography visible Image 6 , the static contact angle of water droplets on the surface of the filter is 155.6°, and the contact angle of edible oil on the surface of the nylon filter is ~0°. Separate 20ml mixture of edible oil and water through a funnel covered with a nylon filter. The separation is completed within 5 minutes. Contact angle, the contact angle is reduced to 152.5°, and the coating surface still maintains superhydrophobicity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com