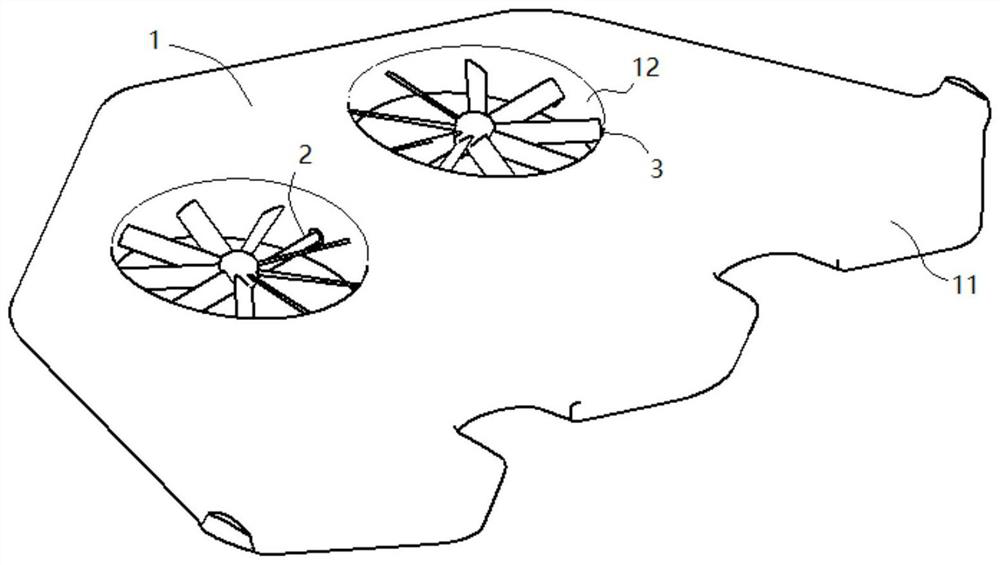

Skeletonless fuselage aircraft with ducted lifting body and design method of fuselage structure

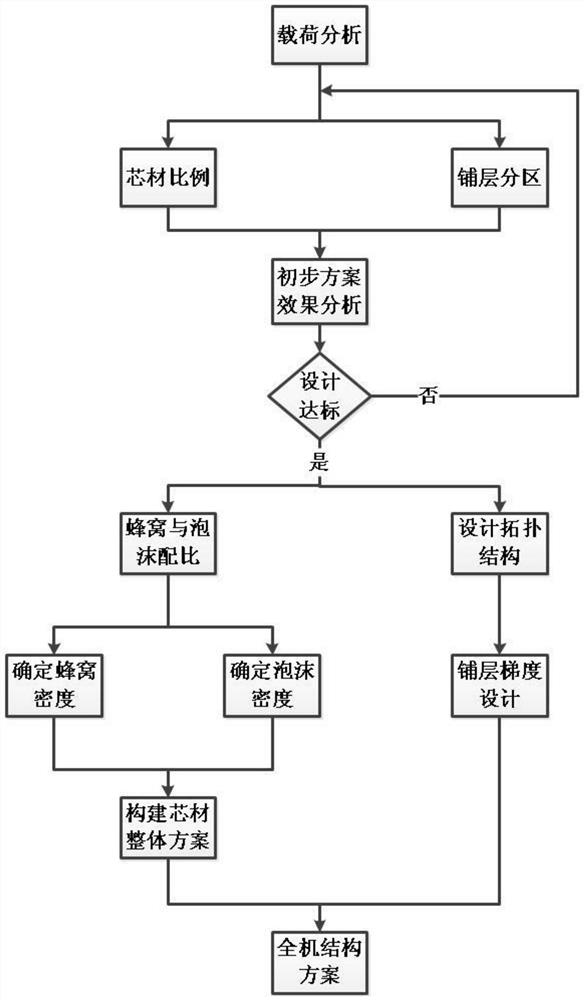

A structural design and aircraft technology, applied in the field of aircraft, can solve the problems of complex fuselage structure and heavy fuselage structure, and achieve the effects of increasing effective load, reducing structural weight, and improving weight efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0045] a) Making an integrated core material by machining or compression molding;

[0046] b) Use dry glass cloth or carbon cloth to glue to the core material at room temperature to form a skin;

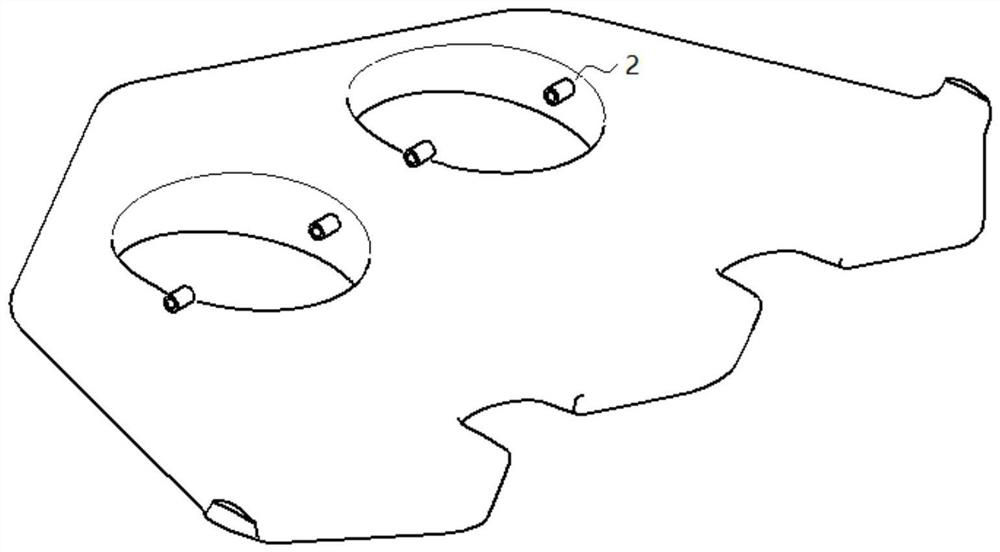

[0047] c) Embedded support structures embedded in rotor or equipment installations.

Embodiment approach 2

[0049] a) Making block core materials by machining or compression molding;

[0050] c) bonding the segmented core materials together by means of cementation to form a complete core material;

[0051] c) Glass cloth prepreg or carbon cloth prepreg is glued to the core material to form a skin under heating and pressure;

[0052] d) Embedded support structures embedded in rotor or equipment installations.

Embodiment approach 3

[0054] a) Making an integrated core material by machining or compression molding;

[0055] b) Glass cloth prepreg or carbon cloth prepreg is glued to the core material to form a skin under heating and pressure;

[0056] c) Embedded support structures embedded in rotor or equipment installations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com